Superhydrophobic fibrofelt and its preparation method

A fiber mat and super-hydrophobic technology, applied in fiber type, fiber treatment, plant fiber, etc., to achieve excellent weather resistance, improve binding force, reduce mold growth and even odor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

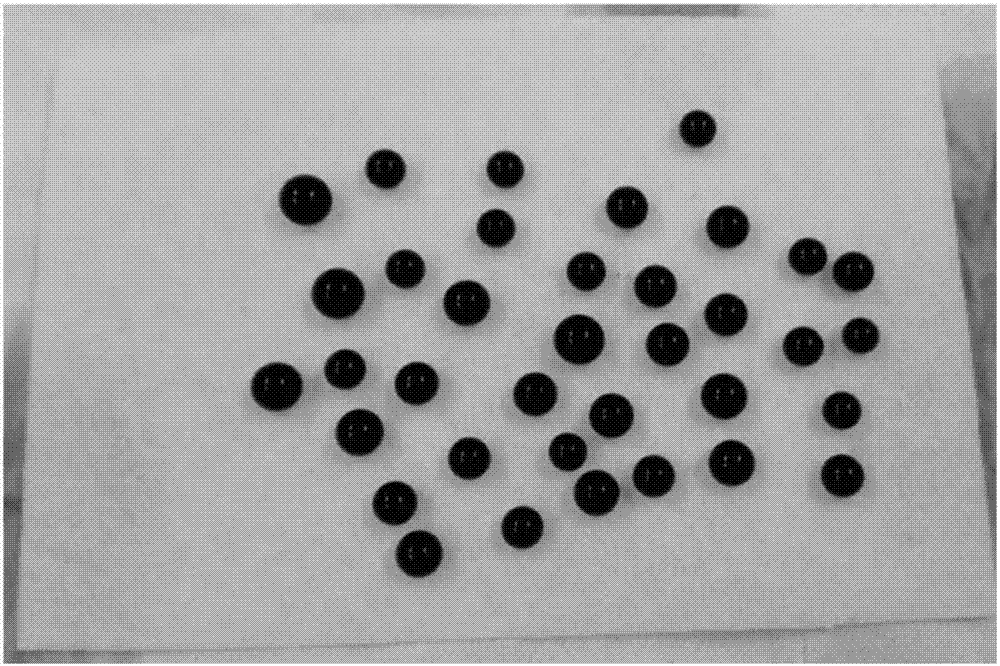

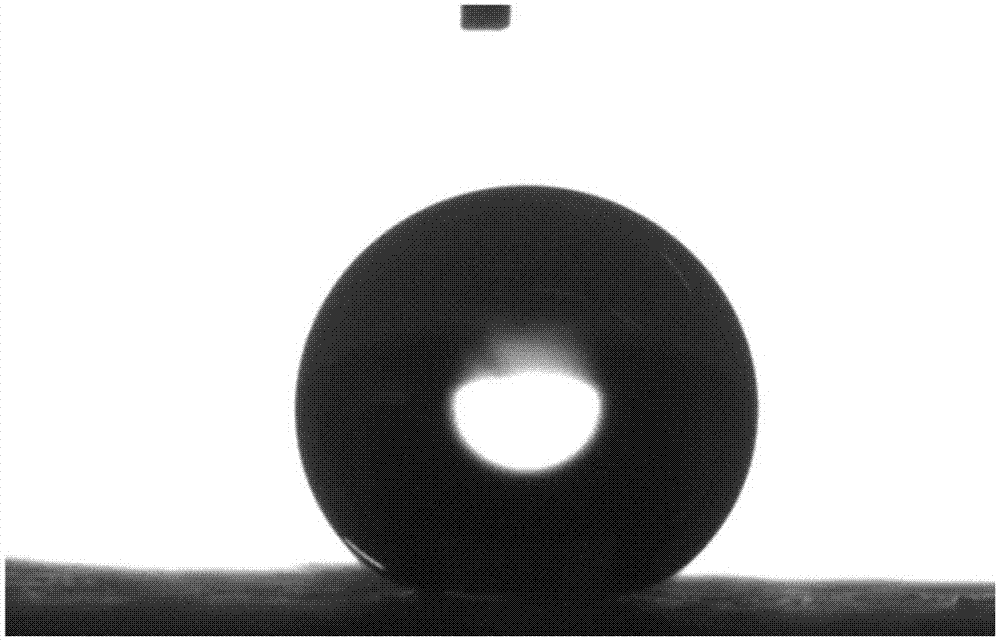

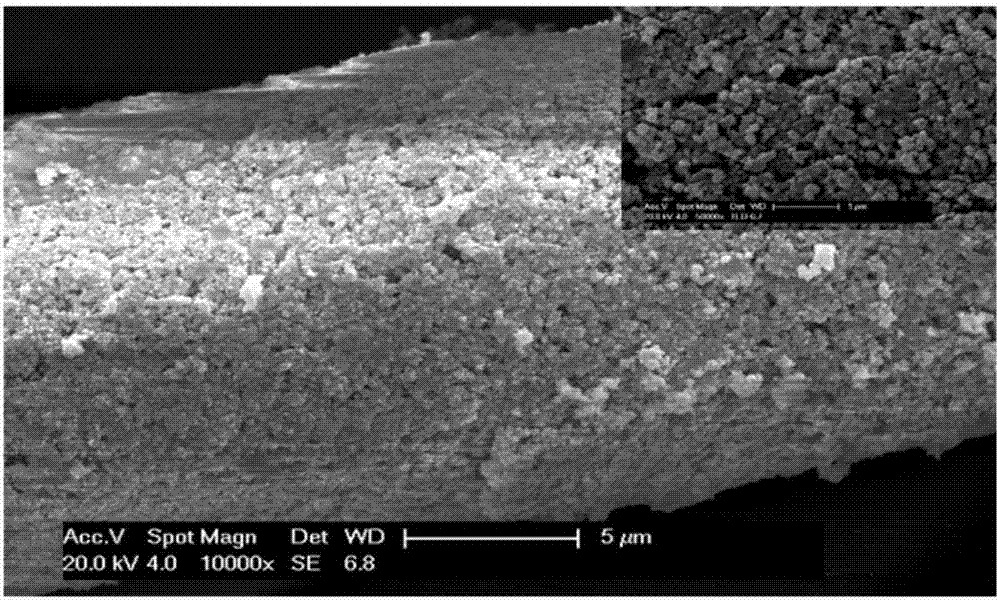

[0021] In this embodiment, the anti-fouling, moisture-proof and mildew-proof superhydrophobic fiber felt is prepared according to the following steps:

[0022] (1) Cleaning of the fiber mat: Place the fiber mat in acetone, absolute ethanol and deionized water in sequence, ultrasonically clean it with a 400w ultrasonic cleaner for 10 minutes, and dry it in an oven at 80°C for 10 minutes. Ester fiber;

[0023] (2) Primer resin solution preparation: add room temperature curing fluorocarbon resin and two-component rigid polyurethane resin into the solvent, and form a stable resin solution after 800r / min magnetic stirring for 3 minutes, wherein the mass fraction of the resin is 1%, the mass ratio of fluorocarbon resin to two-component rigid polyurethane resin is 0.5:1, and the solvent used is acetone;

[0024] (3) Preparation of superhydrophobic topcoat solution: in parts by mass, directly put 2 parts of hydrophobic fumed silica nanoparticles and 0.5 part of fluorosilane into 100 ...

Embodiment 2

[0028] In this embodiment, the anti-fouling, moisture-proof and mildew-proof superhydrophobic fiber felt is prepared according to the following steps:

[0029] (1) Cleaning of the fiber mat: place the fiber mat in acetone, absolute ethanol and deionized water in sequence, ultrasonically clean it with a 400w ultrasonic cleaner for 10 minutes, and dry it in an oven at 80°C for 10 minutes. The fiber mat used is paper Quality fiber;

[0030] (2) Primer resin solution preparation: add room temperature curing fluorocarbon resin and two-component rigid polyurethane resin into the solvent, and form a stable resin solution after 800r / min magnetic stirring for 3 minutes, wherein the mass fraction of the resin is 1%, the mass ratio of fluorocarbon resin to two-component rigid polyurethane resin is 0.5:1, and the solvent used is acetone;

[0031] (3) Preparation of superhydrophobic topcoat solution: in parts by mass, directly put 2 parts of hydrophobic fumed silica nanoparticles and 0.5 ...

Embodiment 3

[0034] In this embodiment, the anti-fouling, moisture-proof and mildew-proof superhydrophobic fiber felt is prepared according to the following steps:

[0035](1) Cleaning of the fiber felt: place the fiber felt in acetone, absolute ethanol and deionized water in turn, ultrasonically clean them with a 400w ultrasonic cleaner for 10 minutes, and dry them in an oven at 80°C for 10 minutes. The fiber felt used is cotton fiber;

[0036] (2) Primer resin solution preparation: add room temperature curing fluorocarbon resin and two-component rigid polyurethane resin into the solvent, and form a stable resin solution after 800r / min magnetic stirring for 3 minutes, wherein the mass fraction of the resin is 1%, the mass ratio of fluorocarbon resin to two-component rigid polyurethane resin is 2:1, and the solvent used is a mixed solvent of acetone and tetrahydrofuran;

[0037] (3) Preparation of superhydrophobic topcoat solution: in parts by mass, directly put 2 parts of hydrophobic fum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com