Spacecraft shell material as well as RTM (Resin Transfer Molding) molding technology and injection molding system thereof

A shell material and injection system technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems that cannot be effectively solved, the porosity of composite material products is large, and the reliability of the overall structure is reduced. problem, to achieve the effect of improving reliability and comprehensive performance, reducing preparation cost, and enhancing multifunctionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

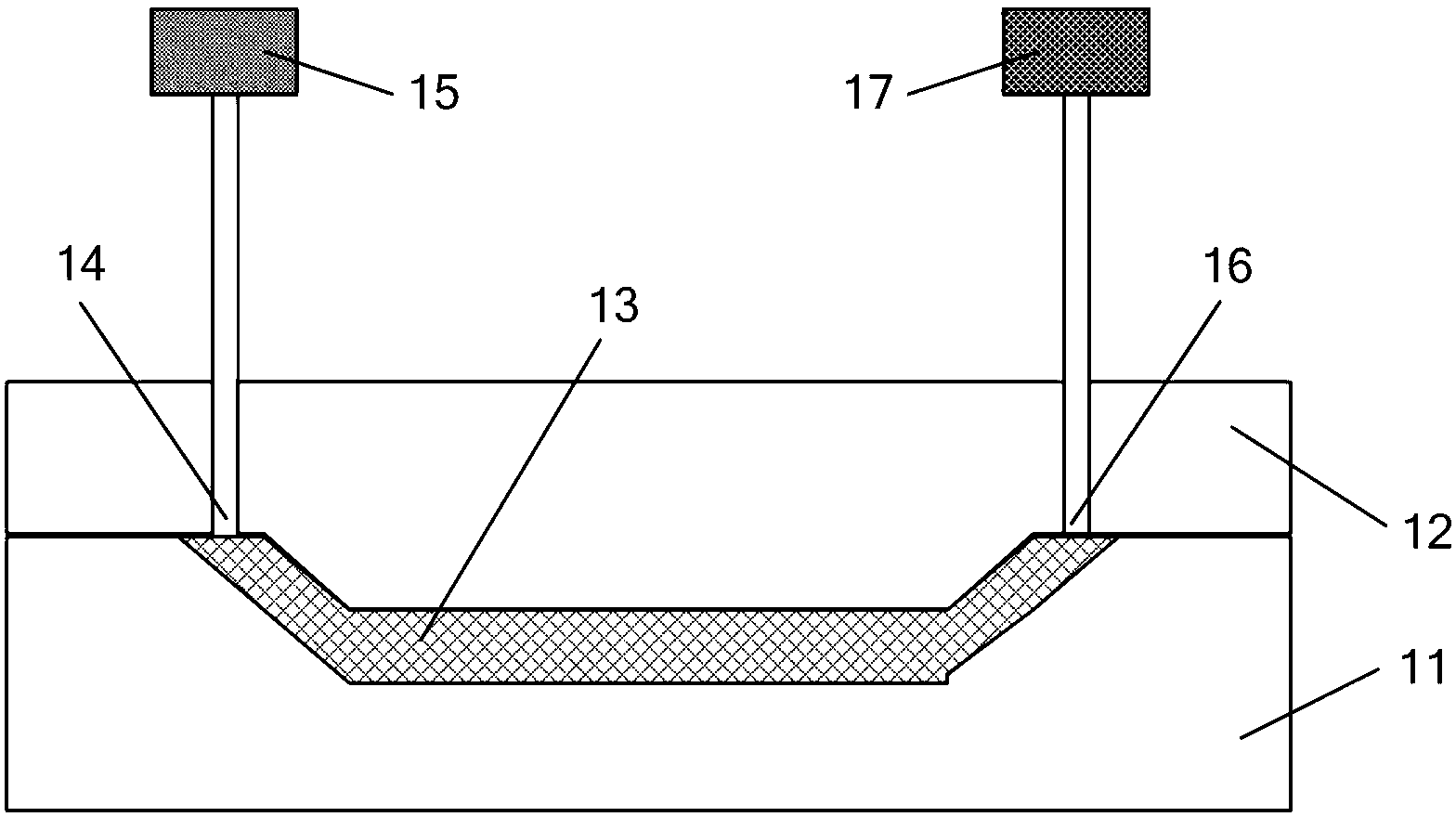

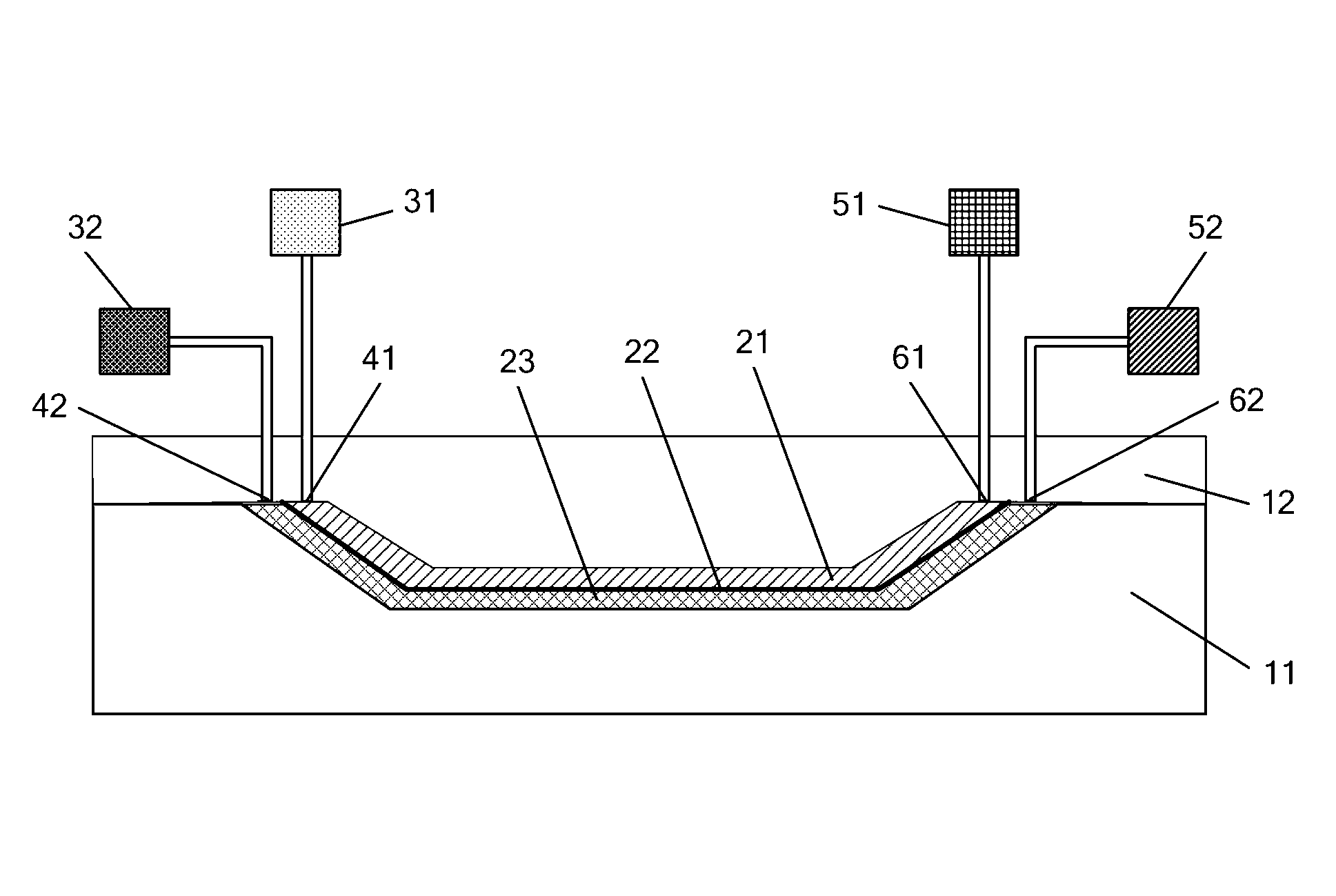

[0033] Embodiment: spacecraft cabin shell and RTM molding thereof.

[0034] a kind of like image 3 As shown in the spacecraft cabin shell of the present invention, the outer layer of the spacecraft cabin shell needs to bear aerodynamic heat, and needs to have functions such as heat resistance, high temperature resistance, and ablation resistance, and the inner layer is mainly used for carrying and receiving Force, must have good mechanical properties. The shell material in this embodiment is mainly composed of an inner layer composite material and an outer layer composite material. The inner layer composite material is made of E-44 epoxy resin (purchased from Yueyang Baling Petrochemical Co., Ltd.) and aromatic amine GA-327 The curing agent (purchased from Jiangsu Yixing Jiangnan Medical Chemical Factory) system is the inner matrix, in which, the viscosity of E-44 epoxy resin is lower than 800mPa·s in the temperature range of 60℃~90℃, and the viscosity is below 800mPa·s T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com