Sulfonated polyethersulfone membrane, preparation method thereof and sulfonated polysulfone membrane as well as preparation method and application thereof

A technology of sulfonated polyethersulfone membrane and sulfonated polysulfone membrane, applied in the fields of sulfonated polyethersulfone membrane and its preparation, bipolar membrane electrodialysis device and separation of amino acid mixture, sulfonated polysulfone membrane and its preparation , can solve the problems of low separation efficiency, reduce the degree of separation of amino acids, and high resistance to macromolecular transmission, and achieve the effects of easy migration through the membrane, improved separation efficiency and current efficiency, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Specifically, the application also provides a method for preparing a sulfonated polyethersulfone membrane, including:

[0045] The sulfonated polyethersulfone is subjected to phase inversion in water to obtain a sulfonated polyethersulfone membrane.

[0046] In the process of preparing the sulfonated polyethersulfone membrane, the preparation of the sulfonated polyethersulfone has been described in detail above, and will not be repeated here. The phase inversion process is carried out in water, and the preparation of the sulfonated polyethersulfone membrane is specifically as follows:

[0047] mixing sulfonated polyethersulfone with an organic solvent to obtain a coating solution;

[0048] Coating the coating solution on the substrate, and soaking in water to obtain a sulfonated polyethersulfone membrane; the organic solvent is N-methylpyrrolidone or a mixed solution of N-methylpyrrolidone and dichloromethane; The temperature of the water is 0-35°C.

[0049] In the p...

Embodiment 1

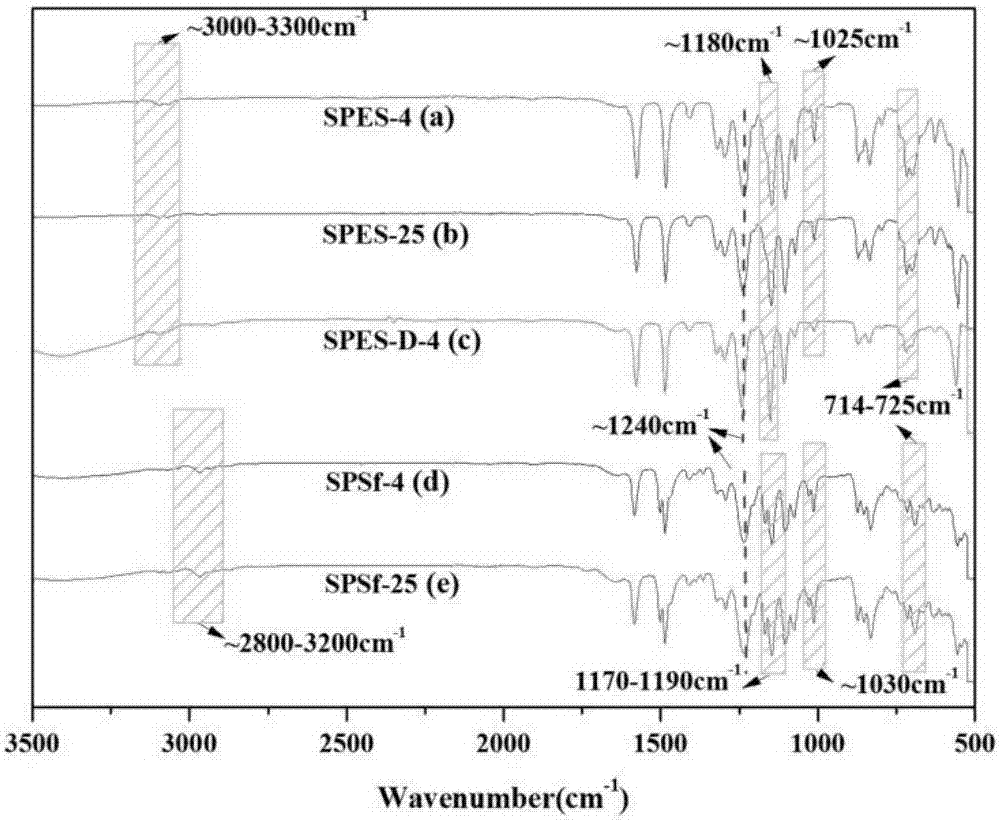

[0089] Example 1 Preparation of Porous Sulfonated Polyethersulfone Membrane SPES-4 by Phase Inversion at Low Temperature

[0090] (1) Preparation of sulfonated polyethersulfone: 2kg polyethersulfone and 6.7L dichloromethane are mixed and added to the reaction kettle, and 6.8L dichloromethane solution is added while stirring to completely dissolve the polyethersulfone; then 1.5L Dichloromethane and 0.5L chlorosulfonic acid were mixed and added to the reaction kettle in two batches, stirred while adding, and reacted at 40°C for 20h; then the mixed solution was discharged from the bottom of the reaction kettle, put into 45°C water for precipitation, and obtained The solid was crushed with a crusher to obtain sulfonated polyethersulfone powder, which was washed with water until the cleaning solution was neutral, then filtered and dried at 90°C for 24 hours to obtain a finished sulfonated polyethersulfone product. The ion exchange capacity of sulfonated polyethersulfone was tested ...

Embodiment 2

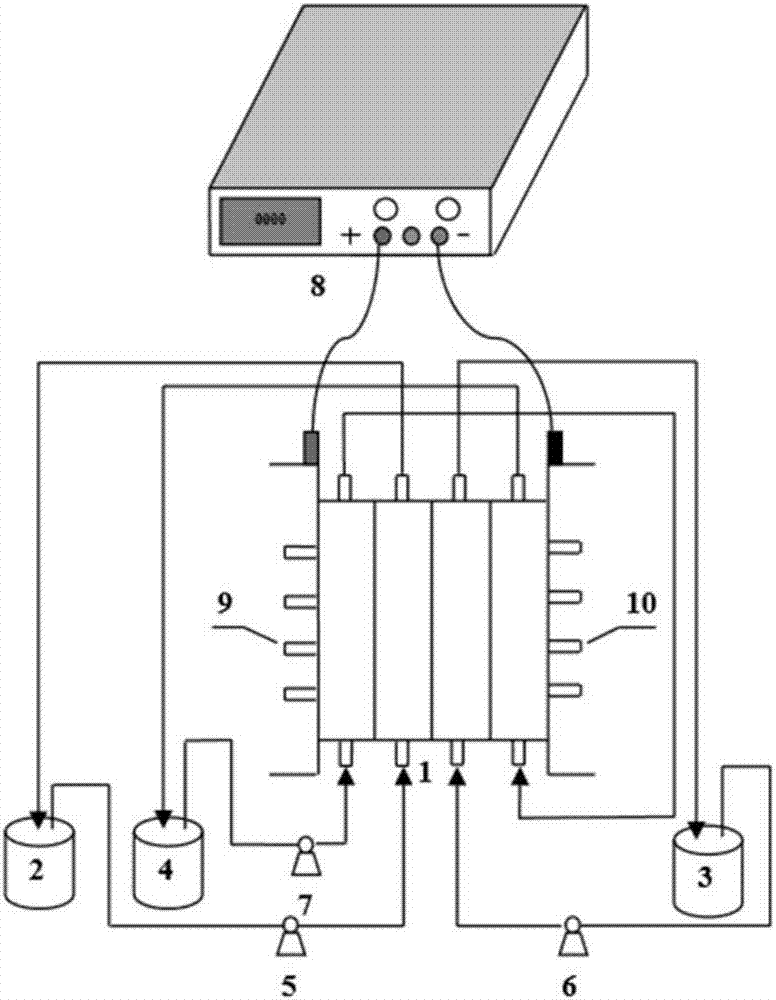

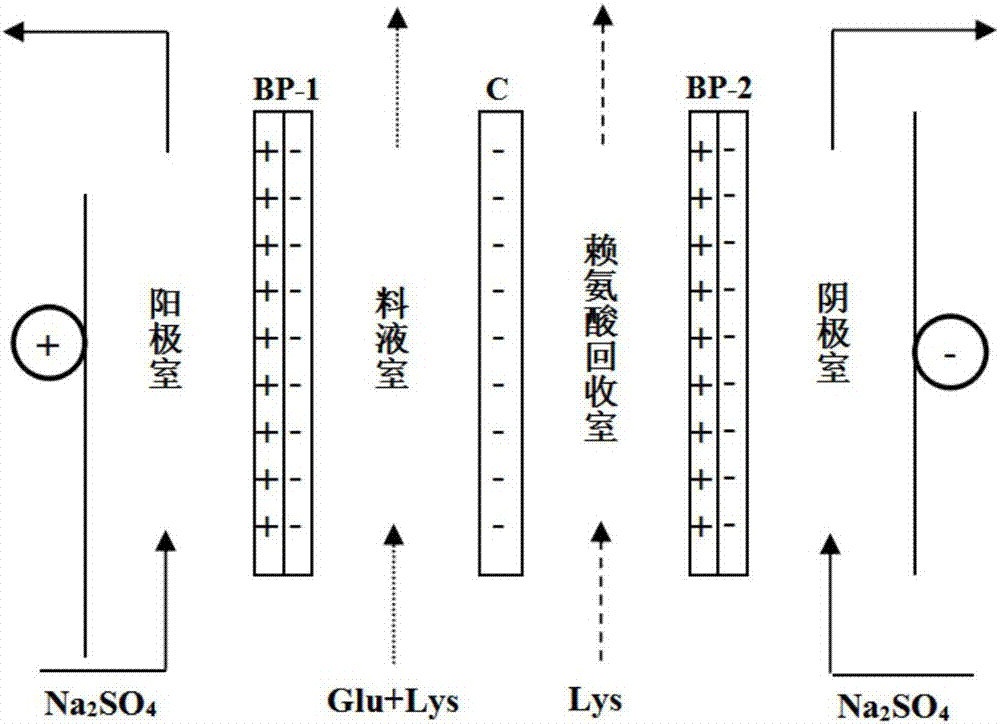

[0098] Example 2 Porous Sulfonated Polyethersulfone Membrane SPES-4 Separation of Amino Acids by Bipolar Membrane Electrodialysis (BMED)

[0099] Carry out BMED experiment to the SPES-4 film that embodiment 1 obtains, and BMED device schematic diagram is as figure 1 , The BMED device consists of a membrane stack device (1), a feed liquid tank (2), a recovery tank (3), an electrode liquid tank (4), a first peristaltic pump (5), a second peristaltic pump (6), a third peristaltic pump Pump (7), DC power supply (8), anode plate (9) and cathode plate (10); the bipolar membranes (BP-1) and (BP-2) used in the membrane stack device (1) are German Fumatech The FBM membrane provided by the company, the cation exchange membrane (C) is the SPES-4 membrane prepared in Example 1; the placement sequence of different membranes is as follows figure 2 As shown, from the anode to the cathode, the bipolar membrane (BP-1), cation exchange membrane (C), bipolar membrane (BP-2), plexiglass separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com