Composite hollow fiber membrane and its preparation and application

A fiber composite, hollow technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as large influence and difficulty, and achieve the effect of easy operation, easy control of conditions, and improved selective separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

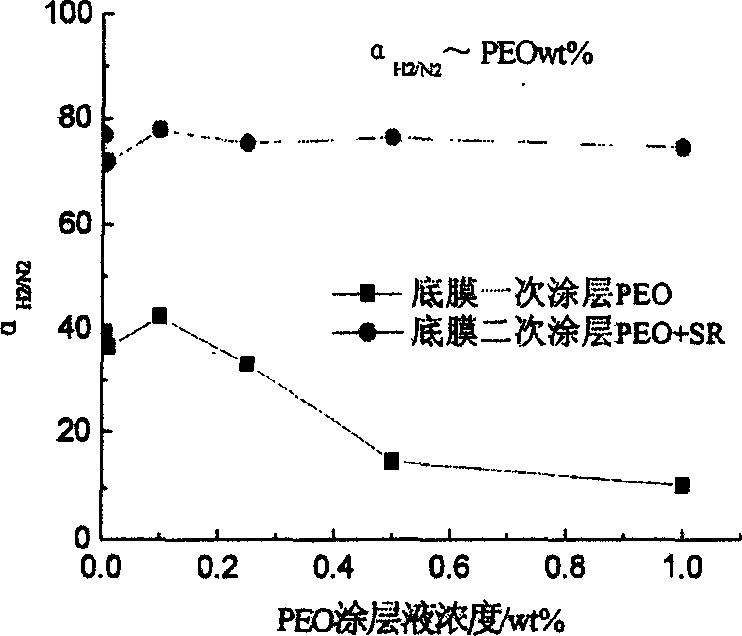

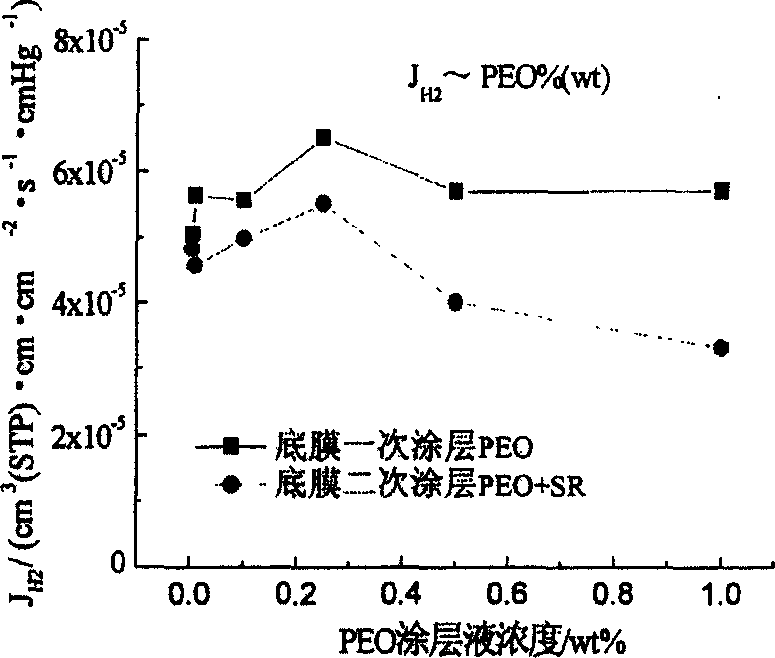

Embodiment 1

[0033] Collect 25 polysulfone hollow fiber asymmetric basement membranes with a monofilament size of 450 μm in outer diameter and 150 μm in inner diameter and 700 mm in length by dry-wet spinning into a bundle, fold them into a “U” shape, and cast the open end with epoxy resin basement membrane. Immerse the filaments in 150mL of PEO coating solution for 15 minutes to complete a coating process, and then dry and solidify naturally for 24 hours after the filaments are taken out. The composition of the PEO coating solution is 0.1wt% PEO, 0.5mL organosilane coupling agent γ-aminopropyltriethoxysilane KH-550, 0.4mL polymer plasticizer dioctyl phthalate DOP, and the rest for H 2 O. Under the conditions of 30°C and 0.5MPa raw material gas, pure H was measured on a self-made evaluation device 2 , pure N 2 The gas permeation rate J through the membrane H2 、J N2 , and calculate the gas ideal separation coefficient α H2 / N2 =J H2 / J N2 . Measured J H2 5.57×10 -5 cm 3 (STP) / cm...

Embodiment 2

[0035] The production and testing methods of the base film are the same as in Example 1. The tow is immersed in 150 mL of polyvinylpyrrolidone PVP coating liquid for 30 minutes to complete a coating process. The composition of the PVP coating solution is 0.5wt% PVP, 0.5mL γ-aminopropyltriethoxysilane KH-550, 0.4mL polymer plasticizer dioctyl phthalate DOP, and the rest is H 2 O. After the silk was taken out, it was naturally dried and solidified for 24 hours, and the measured J H2 7.85×10 -5 cm 3 (STP) / cm 2 s cmHg, α H2 / N2 is 16.1, relative to the basement membrane α H2 / N2 There is improvement.

Embodiment 3

[0037] The production and testing methods of the base film are the same as in Example 1. The tow is immersed in 150 mL of polyvinyl alcohol PVA coating liquid for 30 minutes to complete a coating process. The composition of PVA coating liquid is 0.5wt%PVA, 0.5mLγ-aminopropyltriethoxysilane KH-550, 0.4mL polymer plasticizer dioctyl phthalate DOP, and the rest is H 2 O. After the silk was taken out, it was naturally dried and solidified for 24 hours, and the measured J H2 is 6.09×10 -5 cm 3 (STP) / cm 2 s cmHg, α H2 / N2 is 19.9, relative to the basement membrane α H2 / N2 There is improvement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com