A method for preparing a modified anion-exchange membrane with monovalent selectivity and antibacterial properties

An anion exchange membrane, modification technology, applied in anion exchange, organic anion exchanger, ion exchange and other directions, can solve the problems of anion exchange membrane fouling, precipitation, membrane performance impact, etc., to achieve non-toxic and environmentally friendly preparation process, improve Antibacterial properties, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for preparing an anion exchange membrane with antibacterial surface and monovalent selectivity, comprising the following steps:

[0058] Using a homogeneous Japanese FUJIFILM commercialized anion exchange membrane as the base membrane, rinse the original commercial membrane with 0.2mol / L HCl and 0.2mol / L NaOH solution in sequence, and wash away the impurities on the surface of the membrane and the protective substances attached to the surface of the commercial membrane with deionized water. The membrane was stored in 0.5mol / L NaCl solution for preservation.

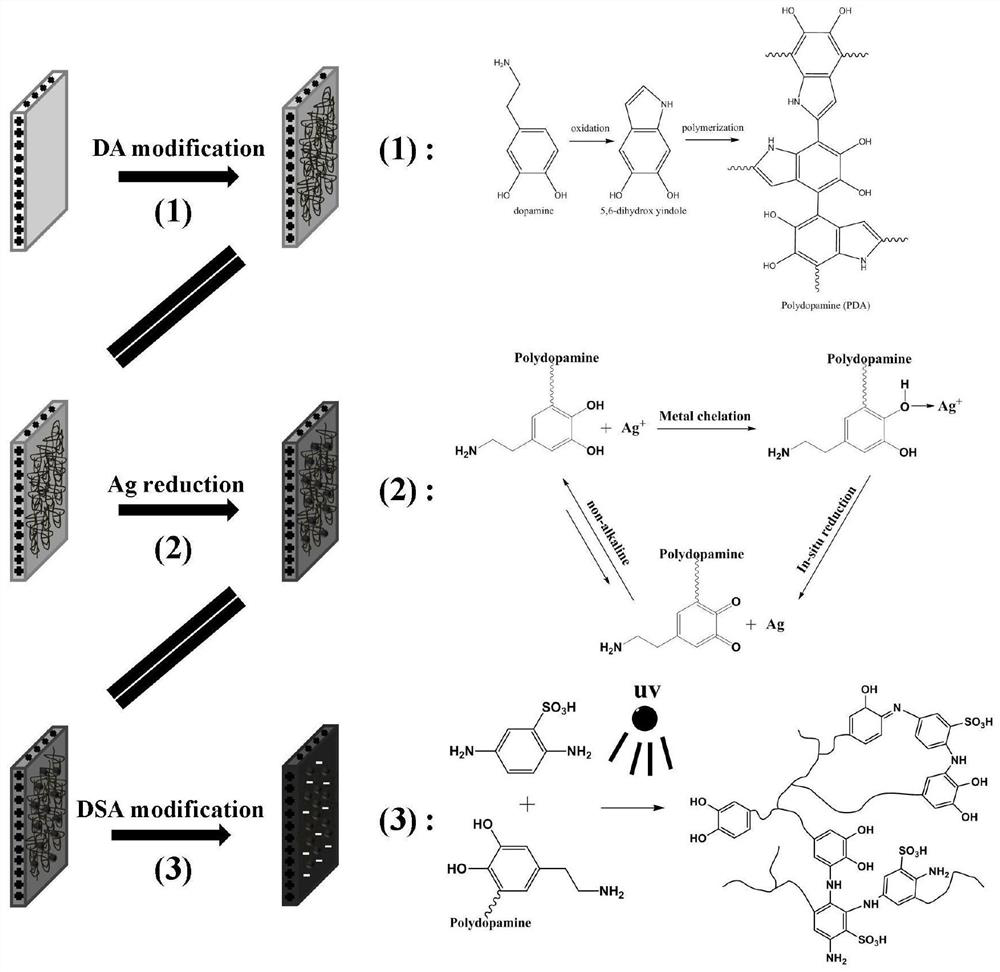

[0059] The preparation process of anion exchange membrane with antibacterial surface and monovalent selectivity is as follows: figure 1 shown.

[0060] Dopamine is dissolved in a Tris buffer solution with a pH of 8.5 to 8.8 to obtain a dopamine Tris mixed solution; the concentration of the Tris buffer solution is 0.01mol / L; the amount of the dopamine added is the volume of the Tris buffer solution Calcul...

Embodiment 2

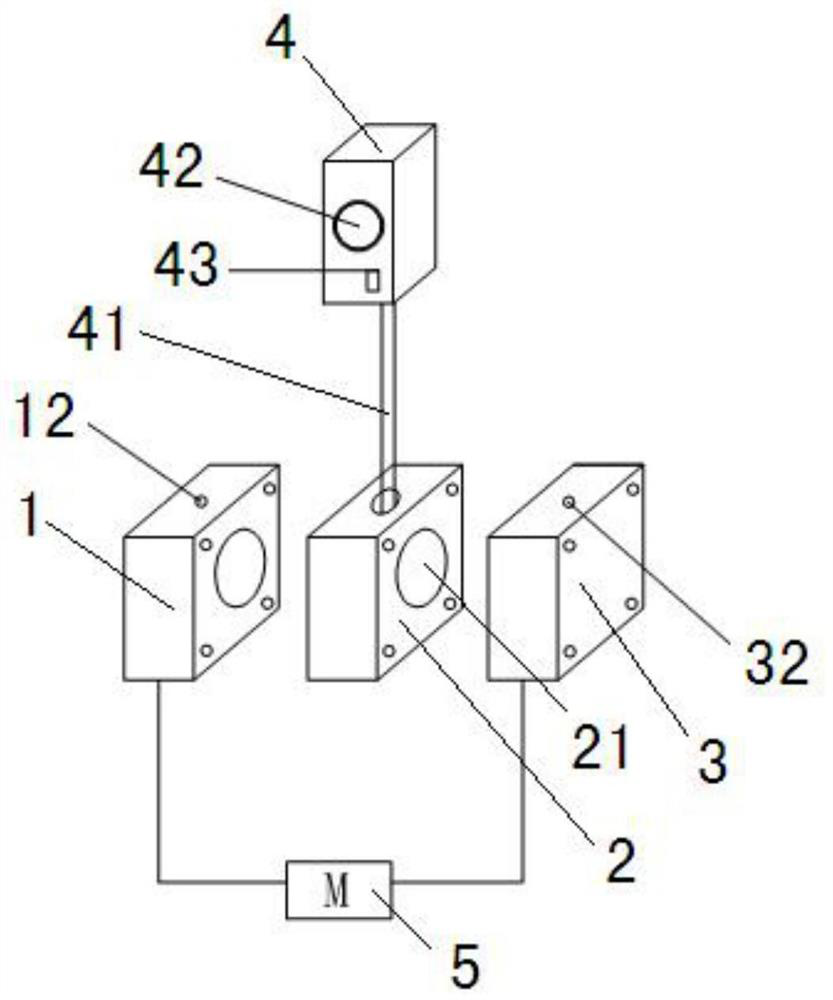

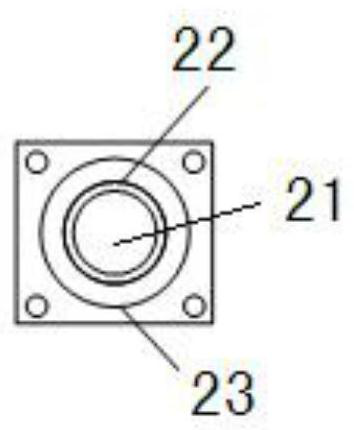

[0065] Example 2: Selectivity Test for Modified Anion Exchange Membrane

[0066] Taking the modified membrane in different modification steps in Example 1 as an example, the membrane was placed in an electrodialysis device for testing. The schematic diagram of the selectivity test of the membrane is shown in image 3 shown. Each chamber has a volume of 100mL and an effective area of 19.625cm 2 . The two middle chambers are the dilute chamber and the concentrated chamber, in which 100mL of 0.05M Na 2 SO 4 Mix the solution with NaCl, add 0.2M Na to the two electrode chambers next to it 2 SO 4 solution as electrolyte. At 5.1mA·cm -2 Operate under the current density, the electrodialysis time is controlled as 120min, and every 30min, the side feed liquid of the dilute chamber is taken to measure its Cl by ion chromatography. - and SO 4 2- concentration. Selective size is given by Indicates that the calculation formula is as follows:

[0067]

[0068] where J i...

Embodiment 3

[0071] Embodiment 3: For the selective stability test of modified anion exchange membrane

[0072] Taking the DA / Ag / DSA modified membrane prepared in Example 1 as an example, the membrane was placed in an electrodialysis device for testing, and the membrane to be tested was stored in 0.5M NaCl solution for one month before testing. The test schematic is as image 3 As shown, the volume of each chamber is 100mL and the effective area is 19.625cm 2 . The two middle chambers are the dilute chamber and the concentrated chamber, in which 100mL of 0.05M Na 2 SO 4 Mix the solution with NaCl, add 0.2M Na to the two electrode chambers next to it 2 SO 4 solution as electrolyte. At 5.1mA·cm -2 Run under the current density, the test time is 80 hours in total, every 2 hours, take the side feed liquid of the dilute chamber and measure Cl by ion chromatography - and SO 4 2- concentration. The feed solution was replaced after each sampling.

[0073] For the selective stability te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com