High-flux and reverse-osmosis composite membrane from eurelon

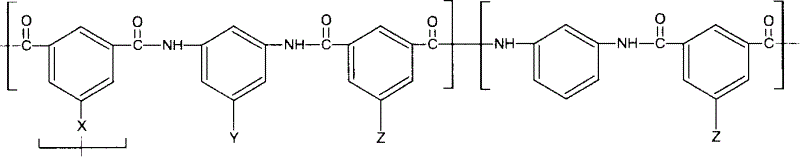

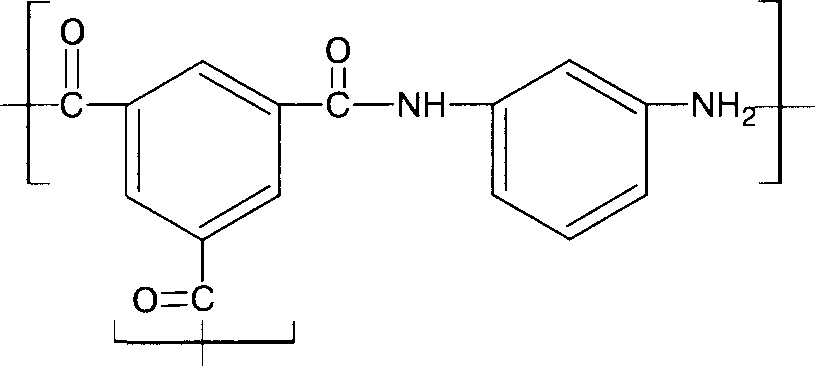

A technology of reverse osmosis composite membrane and polyamide, which is applied in the field of water separation, can solve the problems such as the difficulty of obtaining phenylenediamine, and achieve the effect of increasing water flux and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through examples.

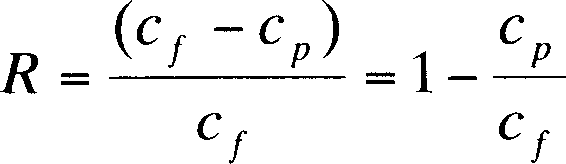

[0021] The operating conditions adopted in the present invention are: 2000ppm sodium chloride aqueous solution, the operating pressure is 225psi, and the operating temperature is 25°C. The following examples give a description of the novel reverse osmosis composite membranes and their desalination performance. However, these examples are provided only by way of illustration and not limitation of the present invention.

[0022] The present invention is to dissolve N,N-dimethylacetamide with 16% Udel P3500 polysulfone, 0.3% water and 0.1% surfactant, apply and scrape on the polyester non-woven fabric, then immerse in water to remove solvent Finally, a supported membrane with a molecular weight cut off (MWCO) of about 20,000 was obtained. Wherein the surfactant includes at least one of alkylphenol polyoxyethyl ester phosphate, sodium dodecylsulfonate and alky...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com