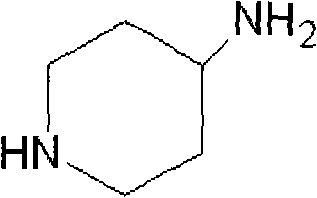

Preparation method for heterocyclic amine composite nanofiltration membrane

A composite nanofiltration membrane and heterocyclic amine technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of piperazine water pollution, non-conformity, etc. Transient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Using a polysulfone support membrane prepared by a DMAc solution containing 18% polysulfone, put it into a 1.2% aqueous solution of 4-aminopiperidine containing 0.05% sodium dodecylsulfonate for about two minutes (SDS), the mass concentration of sodium phosphate and sodium hydrogen phosphate mixture in 4-aminopiperidine aqueous solution is 0.3%, and the pH of 4-aminopiperidine aqueous solution is 10. After soaking in the 4-aminopiperidine solution, use a rubber roller to remove excess 4-aminopiperidine solution on the front and back sides. Then this support membrane was contacted with an organic solution containing 0.2% trimesoyl chloride for 30 seconds, and the organic solvent was trifluorotrichloroethane; an ultrathin polypiperidine amide layer was formed, and then the membrane was placed in a 60°C Keep it in a vacuum oven for 14 minutes to form polypiperidine amide composite nanofiltration

[0022] The initial performance of the membrane was tested under a pressure ...

Embodiment 2

[0025] Using a polysulfone support layer composed of 17% polysulfone in DMAc solution, put it into 1.5% 4-aminopiperidine aqueous solution containing 0.12% sodium dodecylsulfonate for about two minutes (SDS); the mass concentration of sodium phosphate and sodium hydrogen phosphate mixture in 4-aminopiperidine aqueous solution is 0.5%, and the pH of 4-aminopiperidine aqueous solution is 9. After soaking in the 4-aminopiperidine solution, use a rubber roller to remove excess solution on the front and back. Then this support membrane was contacted with an organic solution containing 0.4% trimesoyl chloride for 60 seconds, and the organic solvent was trifluorotrichloroethane; an ultrathin polypiperidine amide layer was formed, and then the membrane was placed in a 70°C Keep it in a vacuum oven for 12 minutes to form a polypiperidine amide composite nanofiltration membrane.

[0026] The initial performance of the membrane was tested under a pressure of 1 MPa with 2000 ppm Na2SO4 a...

Embodiment 3

[0029] Using a polysulfone support layer composed of 15% polysulfone in DMAc solution, put in 1.8% 4-aminopiperidine aqueous solution containing 0.2% sodium dodecylsulfonate for about four minutes (SDS); the mass concentration of sodium phosphate and sodium hydrogen phosphate mixture in 4-aminopiperidine aqueous solution is 0.8%, and the pH of 4-aminopiperidine aqueous solution is 11. After soaking in the 4-aminopiperidine aqueous solution, the excess solution on the front and back of the support membrane was removed with a rubber roller. Then this supporting membrane was contacted with an organic solution containing 0.4% trimesoyl chloride for 150 seconds, the organic solvent heptane; an ultrathin polypiperidine amide layer was formed through interfacial polymerization, and then the membrane was placed in a 75°C Keep it in a vacuum oven for 12 minutes to form a polypiperidine amide composite nanofiltration membrane.

[0030] With 2000ppm (one millionth of the mass concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com