Preparation method of anti-pollution hydrophilic polysulfone membrane modified by amphiphilic amino acid

A chloromethylated polysulfone membrane, polysulfone membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, can solve problems such as application limitations, difficult synthesis, lack of reactive groups, etc. Long service life, stable performance, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

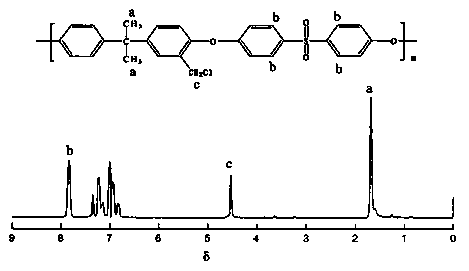

[0040] Embodiment 1: Preparation of chloromethylated polysulfone membrane

[0041] Weigh 1g anhydrous zinc chloride and dissolve in 15ml chloromethyl ether to make complex. Add 10g of polysulfone particles to a dry round bottom flask, then add 100ml of dichloromethane, stir at room temperature to dissolve. The complex was slowly added to the above solution under vigorous stirring, and stirred and refluxed at 40° C. for 5 h. After the reaction is over, pour the reactants in the bottle into a vigorously stirred solution of methanol and water (1:1, v / v), and colloidal chloromethylated polysulfone precipitates out, and repeat the process with hot water at about 70°C. Wash until no bubbles escape, and dry under vacuum at 60°C.

[0042] Dissolve the dried blocky solid in N,N-dimethylacetamide, pour it into distilled water to wash several times after it is completely dissolved, and dry it in vacuum at 65°C for 24 hours to obtain chloromethylated polysulfone.

[0043] The chlo...

Embodiment 2

[0044] Embodiment 2: the preparation of azide imidazole sulfonyl hydrochloride

[0045] 8.0 ml of sulfonyl chloride was added dropwise to a suspension of 6.4 g of sodium azide in 100 ml of anhydrous acetonitrile, and the mixture was stirred overnight at room temperature. 13.6g of imidazole was added to the above system in batches under ice bath, moved to room temperature and reacted for 3h, the mixture was diluted with 100ml of ethyl acetate, the organic layer was continuously extracted with 2×100ml of water and 2×100ml of saturated sodium bicarbonate solution, added Dry and filter over anhydrous sodium sulfate.

[0046] Preparation of ethanol solution of hydrochloric acid: add 10.8ml of acetyl chloride to 38ml of absolute ethanol under ice bath, and react for half an hour to obtain the product.

[0047] The ethanol solution of hydrochloric acid was added dropwise to the dried filtrate under an ice bath, and a white solid was precipitated, filtered, and the filter cake was wa...

Embodiment 3

[0048] Embodiment 3: the preparation of azide L-lysine

[0049] Weigh 5g of Boc-L-lysine, 6g of potassium carbonate, and 50mg of copper sulfate pentahydrate into 30ml of methanol, then add 5g of azidoimidazole sulfonyl hydrochloride, and react the mixture at room temperature for 16h , evaporate methanol to dryness, dilute with 30ml of water, and adjust the pH to 2 with 4mol / L hydrochloric acid. Extracted 3 times with 50 ml of ethyl acetate, dried the combined organic layer with anhydrous sodium sulfate, filtered and concentrated to obtain a light yellow viscous substance.

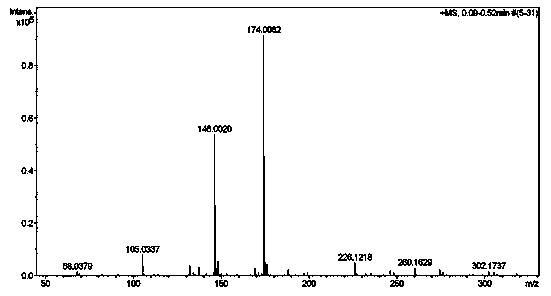

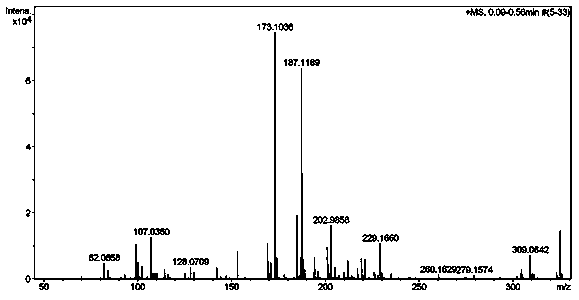

[0050] The light yellow viscous substance obtained in the previous step was moved into a flask equipped with 25ml of anhydrous dichloromethane, and 6.5ml of trifluoroacetic acid was added dropwise to the flask, reacted at room temperature for 4h, and then evaporated to dryness to obtain Azide L-Lysine. Calculated value of HRMS (FAB): C 6 h 13 N 4 o 2 [MH] + m / z173.1039, the measured value is 173....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com