Polyvinyl alcohol composite nanofiltration membrane preparation method

A composite nanofiltration membrane and polyvinyl alcohol technology, which is applied in the field of filtration membranes, can solve the problems of easy shedding of surface inorganic materials, high retention rate of divalent ions, affecting the service life of membranes, etc., and achieves easy industrial production, simple process and low cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

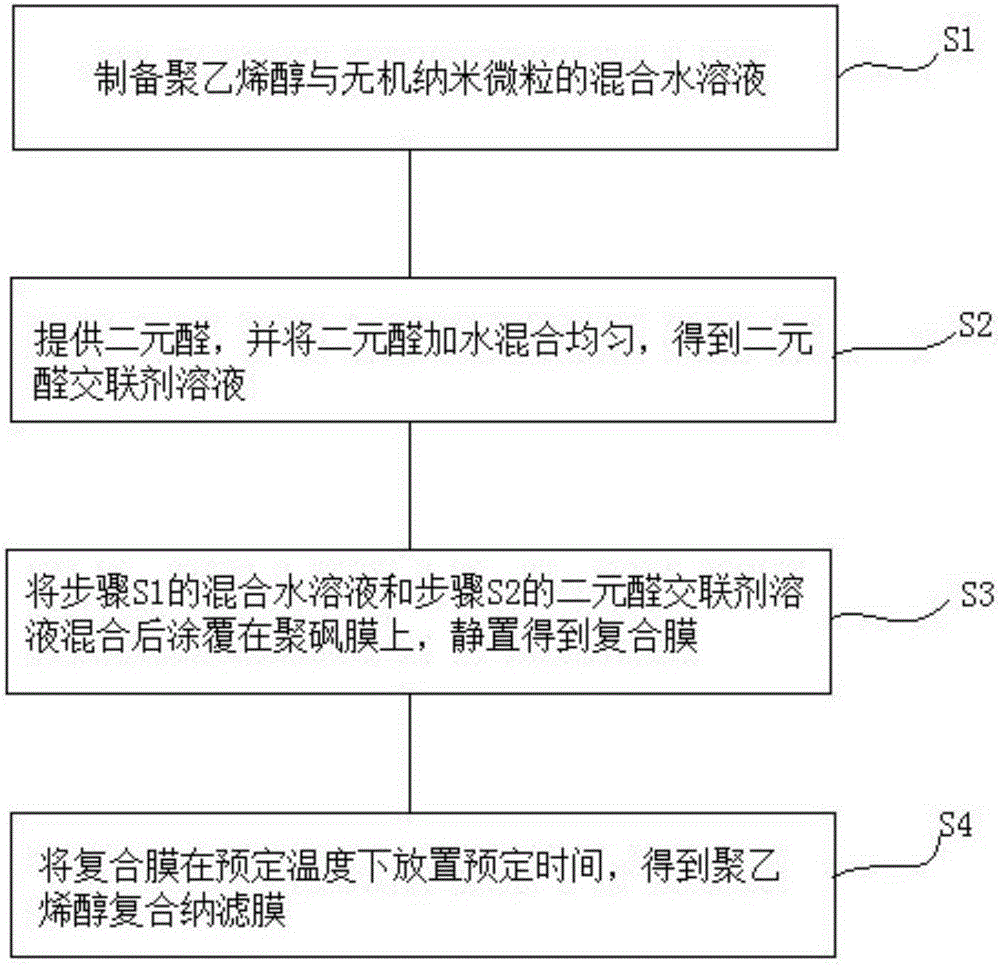

[0026] Such as figure 1 As shown, the preparation method of the polyvinyl alcohol composite nanofiltration membrane according to the embodiment of the present invention comprises the following steps:

[0027] S1. Prepare a mixed aqueous solution of polyvinyl alcohol and inorganic nanoparticles.

[0028] S2. Providing a dialdehyde, and mixing the dialdehyde with water to obtain a dialdehyde crosslinking agent solution.

[0029] S3. Mix the mixed aqueous solution in step S1 and the binary aldehyde crosslinking agent solution in step S2, and then coat it on the polysulfone membrane, and leave it to stand to obtain a composite membrane.

[0030] S4, placing the composite membrane at a predetermined temperature for a predetermined time to obtain a polyvinyl alcohol composite nanofiltration membrane.

[0031] Therefore, according to the preparation method of the polyvinyl alcohol composite nanofiltration membrane of the embodiment of the present invention, the method has simple pr...

Embodiment 1

[0053] Mix 5% polyvinyl alcohol PVA-GH-20 and 0.5% titanium dioxide with a particle size of 50-150 nanometers, add 30% glycerin, dispersant is n-butanol, add 0.4% sulfuric acid after stirring, and then mix with the prepared Mix the 1.8% glutaraldehyde aqueous solution evenly and put it into the feed liquid tank of a small slit extrusion coater, place the wetted polysulfone base film on the coater, and control the coater to mix polyvinyl alcohol and dialdehyde The mixed solution was evenly coated on the polysulfone-based membrane and left to stand for 2 minutes; then the composite membrane was treated at 100°C for 5 minutes to form the polyvinyl alcohol nanofiltration membrane; the molecular weight cut-off of the polysulfone-based membrane was between 4-6 Ten thousand.

[0054] The polyvinyl alcohol composite nanofiltration membrane prepared by the above method has a rejection rate of 2.91% to 200ppmNaCl solution under 0.41MPA, a rejection rate of 10.96% to magnesium sulfate, a...

Embodiment 2

[0056] The preparation method of this example is substantially the same as that of Example 1 above, except that in this example, the polyvinyl alcohol is 4% Selvol540, the inorganic nanoparticles are 0.05% nano-MOF-5, and the heating temperature is adjusted to 100°C.

[0057] The polyvinyl alcohol composite nanofiltration membrane prepared by this method has a rejection rate of 1.54% to 200ppmNaCl solution under 0.41MPA, a rejection rate of 5.8% to magnesium sulfate, a rejection rate of 90.3% to PEG600, and a rejection rate of 80.1% to PEG400. %, the flux is 78LMH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com