Preparation method of membrane material used for adsorbing alkaloid

A membrane material, alkaloid technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problem of filter membrane permeability or low permeability, base membrane adsorption affinity lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

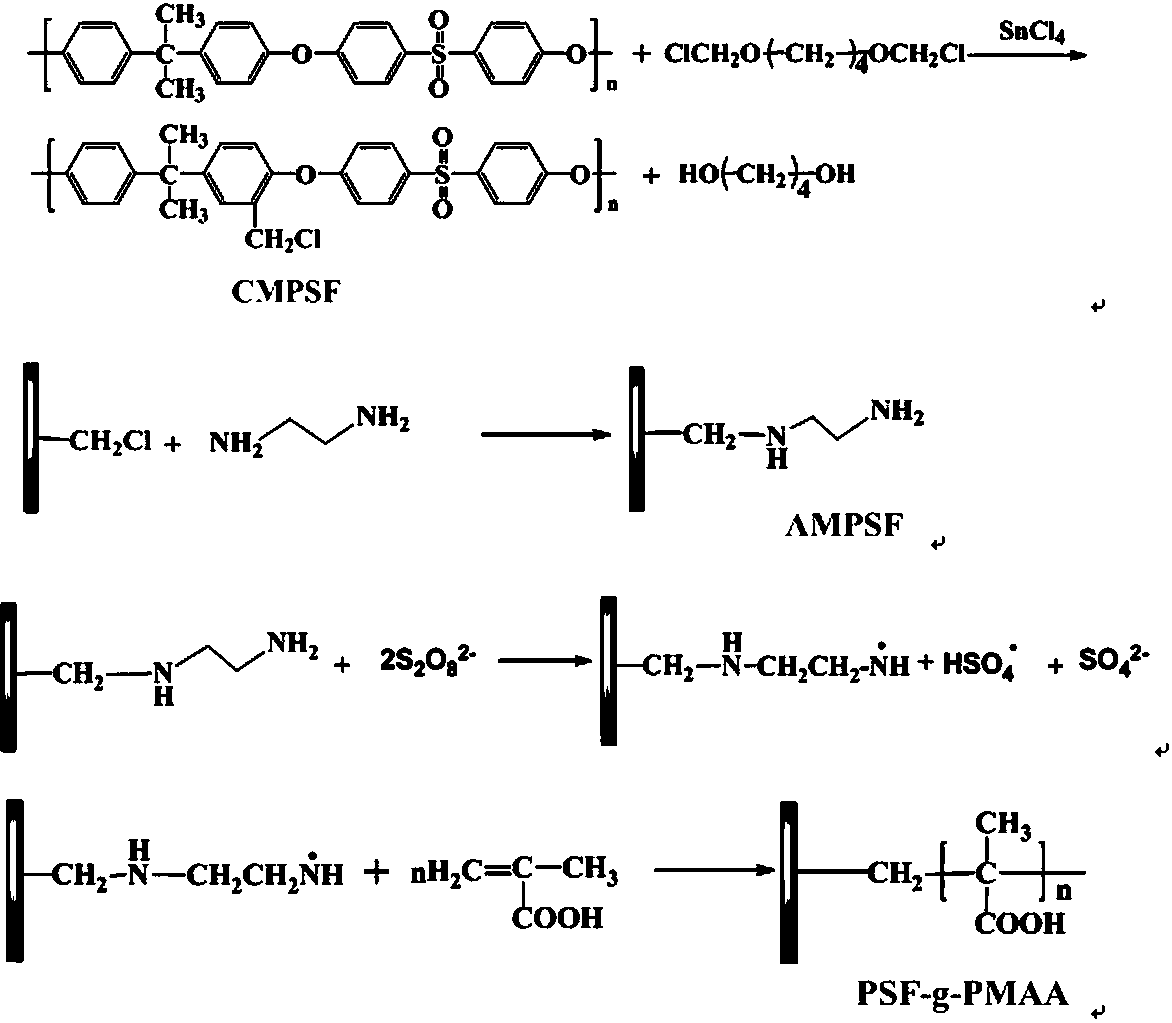

[0038] A method for preparing a membrane material for adsorbing alkaloids, the steps are:

[0039] (1) Preparation of chloromethylated polysulfone casting film:

[0040] Put 2 g of polysulfone into a four-necked flask equipped with a stirrer and a thermometer, add 10 mL of dichloromethane to completely dissolve the polysulfone, then add 2.8 mLd of 1,4-dichloromethoxybutane and 0.26 mL Lewis acid catalyst SnCl 4 , react at 25°C for 3 h, use ethanol as a precipitant to precipitate the product polymer, wash and dry in vacuum to obtain chloromethylated polysulfone CMPSF, then take 0.8g CMPSF and dissolve it in 50mL chloroform, pour it into the culture cast in a dish to form a film, and place it in a vacuum oven to remove the solvent to obtain a chloromethylated polysulfone cast film CMPSF film with a film thickness of about 50 μm;

[0041] (2) Preparation of aminated polysulfone membrane: Soak the CMPSF membrane in ethylenediamine to cause a nucleophilic substitution reaction be...

Embodiment 2

[0046] A method for preparing a membrane material for adsorbing alkaloids, the steps are:

[0047] (1) Preparation of chloromethylated polysulfone casting film:

[0048] Put 2 g of polysulfone into a four-necked flask equipped with a stirrer and a thermometer, add 10 mL of dichloromethane to completely dissolve the polysulfone, then add 2.8 mLd of 1,4-dichloromethoxybutane and 0.26 mL Lewis acid catalyst SnCl 4 , react at 25°C for 3 h, use ethanol as a precipitant to precipitate the product polymer, wash and dry in vacuum to obtain chloromethylated polysulfone CMPSF, then take 0.8g CMPSF and dissolve it in 50mL chloroform, pour it into the culture cast in a dish to form a film, and place it in a vacuum oven to remove the solvent to obtain a chloromethylated polysulfone cast film CMPSF film with a film thickness of about 50 μm;

[0049] (2) Preparation of aminated polysulfone membrane: Soak the CMPSF membrane in ethylenediamine at 25°C to cause a nucleophilic substitution rea...

Embodiment 3

[0053] A method for preparing a membrane material for adsorbing alkaloids, the steps are:

[0054] (1) Preparation of chloromethylated polysulfone casting film:

[0055] Put 2 g of polysulfone into a four-necked flask equipped with a stirrer and a thermometer, add 10 mL of dichloromethane to completely dissolve the polysulfone, then add 2.8 mLd of 1,4-dichloromethoxybutane and 0.26 mL Lewis acid catalyst SnCl 4 , react at 25°C for 3 h, use ethanol as a precipitant to precipitate the product polymer, wash and dry in vacuum to obtain chloromethylated polysulfone CMPSF, then take 0.8g CMPSF and dissolve it in 50mL chloroform, pour it into the culture cast in a dish to form a film, and place it in a vacuum oven to remove the solvent to obtain a chloromethylated polysulfone cast film CMPSF film with a film thickness of about 50 μm;

[0056] (2) Preparation of aminated polysulfone membrane: Soak the CMPSF membrane in ethylenediamine at 25°C to cause a nucleophilic substitution rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com