Bismuth and silicon doped nano titanium dioxide photocatalyst, its preparation and its application

A nano-titanium dioxide and photocatalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of easy recombination of photogenerated electrons and holes, and low photon efficiency. , instability and other problems, to achieve the effect of easy industrial production, easy availability of raw materials, simple synthesis process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Measure 50ml of 0.02 mol / L bismuth nitrate and 50ml of 0.1 mol / L ethyl orthosilicate in absolute ethanol in the reactor, add nitric acid solution to adjust the pH to 2, stir well to obtain a mixed solution; stir at room temperature 100ml 2mol / L tetrabutyl titanate solution in absolute ethanol is slowly added dropwise to the above mixed solution, a white precipitate will appear at the beginning, after the dropwise addition, continue to stir for 10 hours to make the tetrabutyl titanate further Hydrolyze to obtain a monodisperse sol; then dry the sol at 90°C for 8 hours to remove ethanol and water to obtain a xerogel, and calcinate at 450°C for 1.5 hours to obtain a light yellow bismuth and silicon co-doped nano-titanium dioxide photocatalyst, in mole fraction Calculated, the doping amount of bismuth is 0.4%, and the doping amount of silicon is 4.8%.

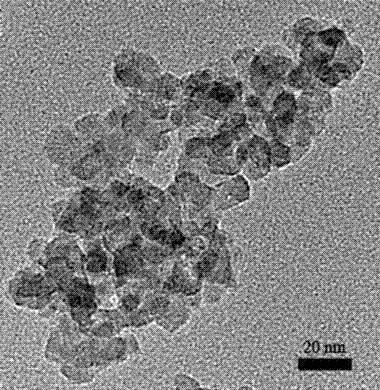

[0029] figure 1 It is the transmission electron microscope photograph of this sample, it can be seen that the sample par...

Embodiment 2

[0031] Measure 50ml of 0.04 mol / L bismuth nitrate and 50ml of 0.2 mol / L ethyl orthosilicate in absolute ethanol in the reactor, add nitric acid solution to adjust the pH to 1.5, stir well to obtain a mixed solution; stir at room temperature Add 200ml of 1mol / L tetrabutyl titanate solution in absolute ethanol dropwise to the above mixed solution, and continue stirring for 8 hours after the dropwise addition to obtain a monodisperse sol; dry the obtained sol at 90°C for 9 hours to dry The gel was calcined at 500°C for 2 hours to obtain a light yellow bismuth-silicon co-doped nano-titanium dioxide photocatalyst. In terms of mole fraction, the doping amount of bismuth was 0.9%, and the doping amount of silicon was 7.6%.

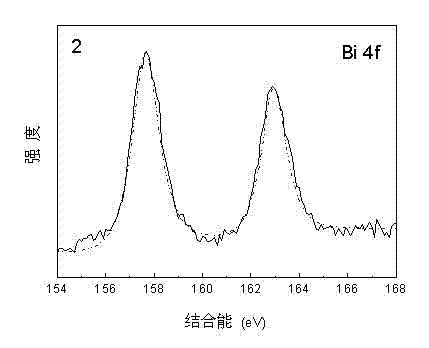

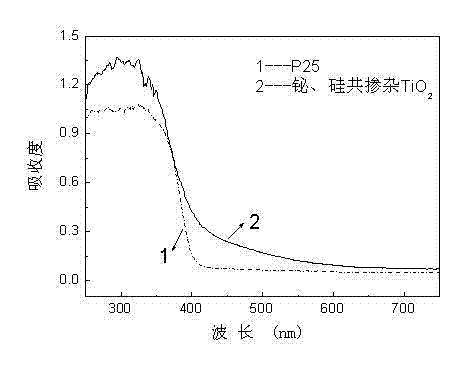

[0032] The X-ray diffraction pattern of the bismuth and silicon co-doped nano-titanium dioxide photocatalyst synthesized in this embodiment shows that its crystal phase is anatase phase, and a certain red shift has taken place in the ultraviolet-visible absorption...

Embodiment 3

[0035] Measure 50ml of 0.01 mol / L bismuth acetate and 50ml of 0.3 mol / L sodium silicate in absolute ethanol in the reactor, add nitric acid solution to it to adjust the pH to 2.5, and stir to obtain a mixed solution; stir 100ml at room temperature Add 2 mol / L isopropyl titanate absolute ethanol solution dropwise to the above mixed solution, and continue stirring for 10 hours after the dropwise addition to obtain a monodisperse sol; dry the obtained sol at 100°C for 8 hours to obtain a xerogel , Calcined at 500°C for 2 hours to obtain a light yellow bismuth and silicon co-doped nano-titanium dioxide photocatalyst, in terms of mole fraction, the doping amount of bismuth was 0.2%, and the doping amount of silicon was 12.1%.

[0036] The X-ray diffraction pattern of the bismuth and silicon co-doped nano-titanium dioxide photocatalyst synthesized in this embodiment shows that its crystal phase is anatase phase, and the ultraviolet-visible absorption spectrum has a red shift to a cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com