Preparation and application of nano zinc oxide photocatalyst

A technology of nano-zinc oxide and photocatalyst, applied in the field of chemistry, can solve the problems of long period of nano-zinc oxide, cumbersome post-treatment process, many components in solution system, etc. Good photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Preparation of Nano ZnO Photocatalyst

[0063] Weigh 1.756g (8mmol) of zinc acetate dihydrate into a beaker, add 40mL of diethylene glycol, and add 80mL of water, then place the beaker in an ultrasonic instrument, adjust the ultrasonic frequency to 100KHz, and ultrasonicate for 2.0h to produce a white precipitate;

[0064] Transfer the obtained white precipitate to a centrifuge tube, use the ultrasonic sedimentation method to settle the white precipitate in the centrifuge tube, and centrifuge at 10000r / min with a centrifuge, wash with absolute alcohol once, wash with distilled water 4 times, and finally The white precipitate was placed in a vacuum drying oven and dried under vacuum at 80°C to obtain a nano-ZnO photocatalyst.

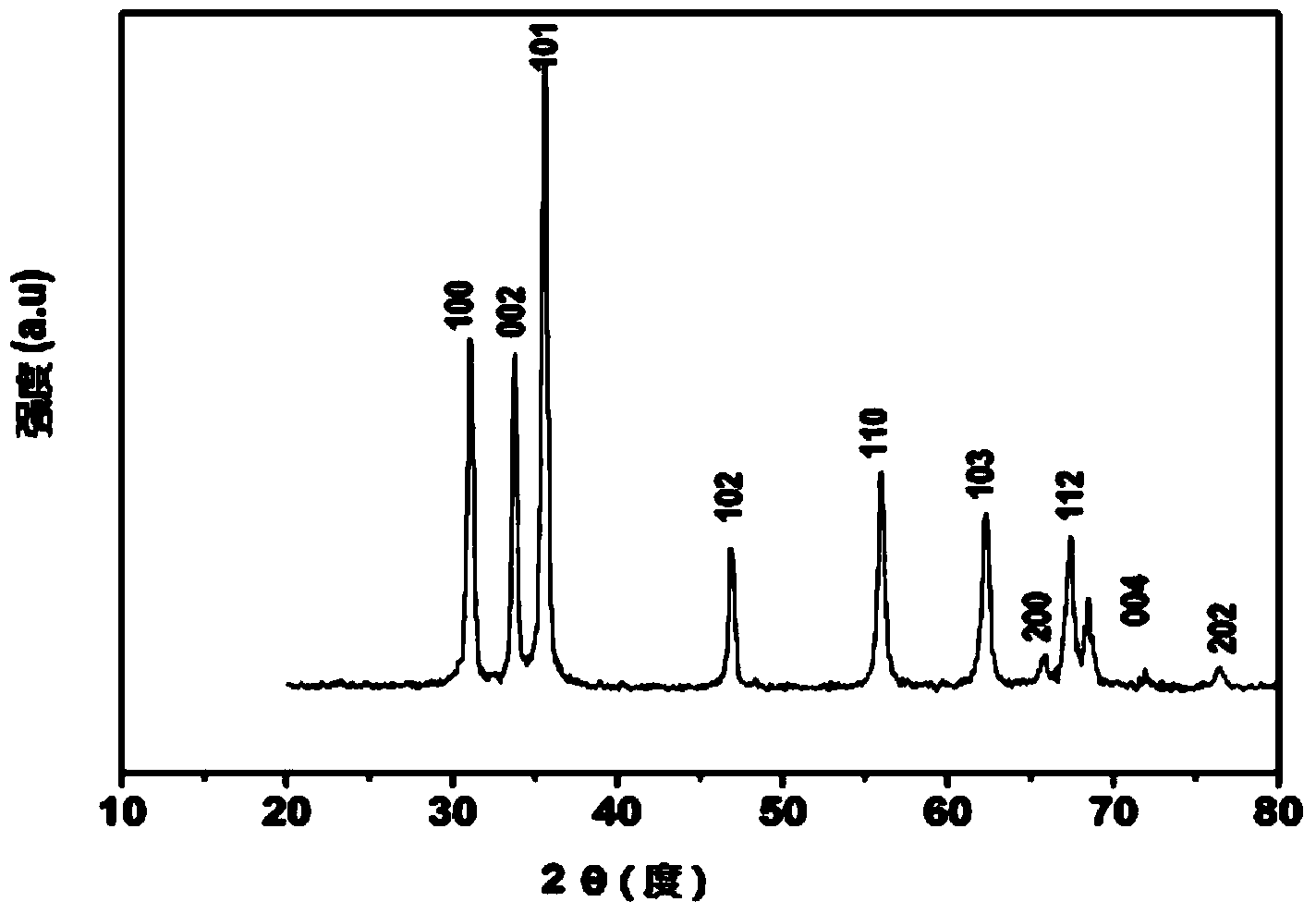

[0065] XRD characterization

[0066] Weigh 0.5g of the above nano-ZnO photocatalyst powder and use the method (1) to perform XRD characterization, and obtain the XRD spectrum of the nano-ZnO photocatalyst, as shown in figure 1 shown.

[0067] A...

Embodiment 2

[0074] Preparation of Nano ZnO Photocatalyst

[0075] Weigh 1.00g of zinc acetate dihydrate into a beaker, and completely dissolve it in 120mL of diethylene glycol, and add 240mL of water, then place the beaker in an ultrasonic instrument, adjust the ultrasonic frequency to 120KHz, ultrasonic 5.0h, in the system Dispersed with white precipitate;

[0076] Transfer the obtained white precipitate to a centrifuge tube, use the ultrasonic sedimentation method to settle the white precipitate in the centrifuge tube, and centrifuge at 12000r / min with a centrifuge, wash it twice with 95% alcohol, wash it five times with distilled water, and finally wash the white The precipitate was placed in a vacuum drying oven and dried under vacuum at 200° C. to obtain a nanometer ZnO photocatalyst.

[0077] XRD characterization

[0078] Weigh 0.5g of the above-mentioned nano-ZnO photocatalyst powder and perform XRD characterization by the method (1), and obtain the XRD spectrum of the nano-ZnO p...

Embodiment 3

[0082] Preparation of Nano ZnO Photocatalyst

[0083] Weigh 5.00g of zinc acetate dihydrate into a beaker, add 40.0mL of water, and completely dissolve it in 20.0mL of diethylene glycol, then place the beaker in an ultrasonic instrument, adjust the ultrasonic frequency to 130KHz, ultrasonic 1.0h, the system Dispersed with white precipitate;

[0084] Transfer the obtained white precipitate to a centrifuge tube, use the ultrasonic sedimentation method to settle the white precipitate in the centrifuge tube, and centrifuge with a centrifuge at 8000r / min, wash it twice with absolute alcohol, wash it five times with distilled water, and finally The white precipitate was placed in a vacuum oven and dried under vacuum at 40°C to obtain a nano-ZnO photocatalyst.

[0085] XRD characterization

[0086] Weigh 0.5g of the above-mentioned nano-ZnO photocatalyst powder and perform XRD characterization by the method (1), and obtain the XRD spectrum of the nano-ZnO photocatalyst, which is si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com