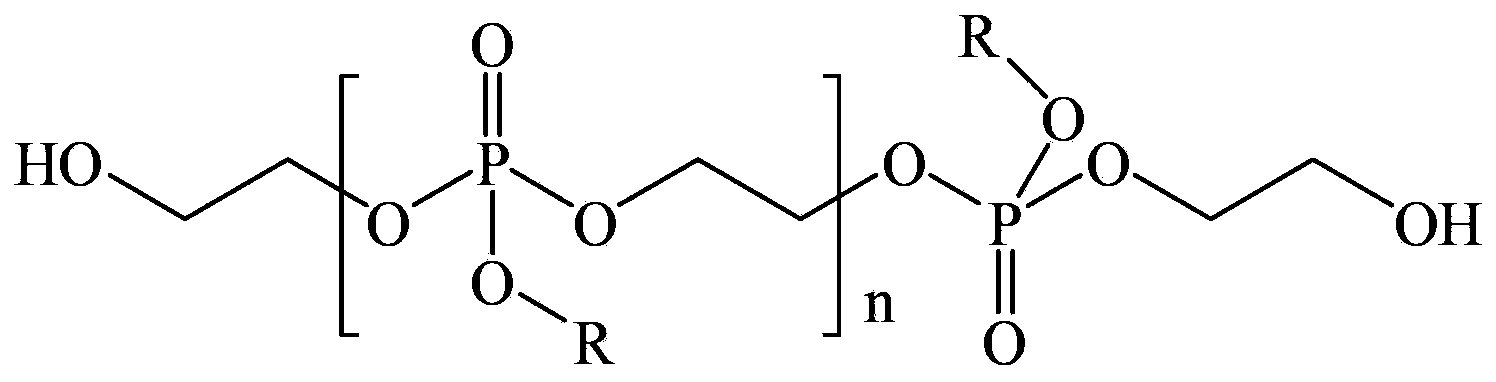

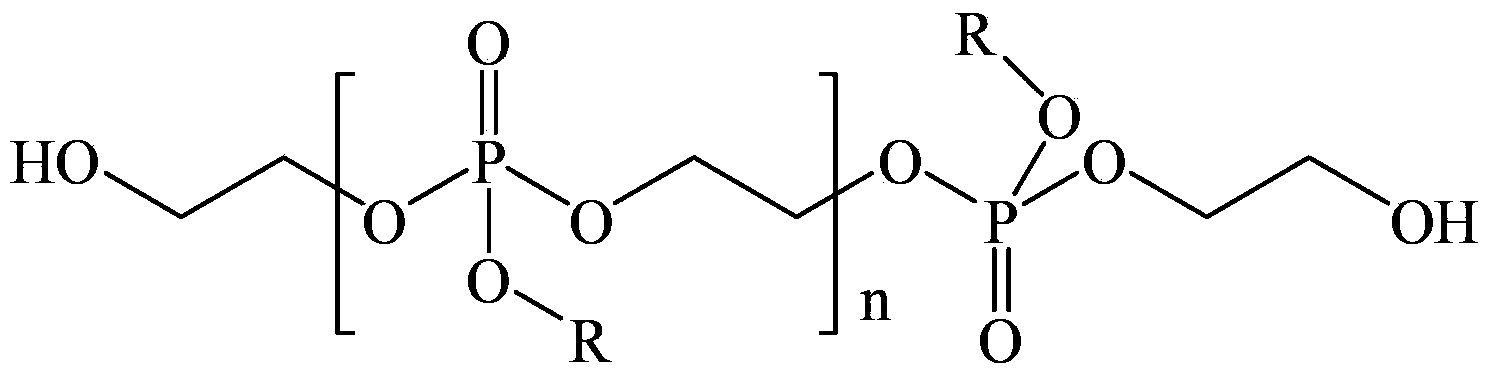

Halogen-free organophosphate fire retardant and its preparation method

A technology of organic phosphate and flame retardant, which is applied in the field of flame-retardant polyurethane foam, can solve problems such as toxic residues, and achieve the effect of environmental protection and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

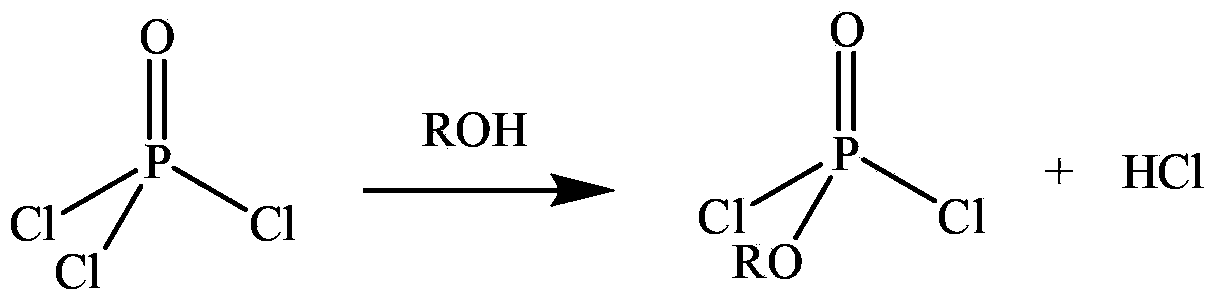

[0045] Embodiment 1: the preparation of organophosphate of the present invention

[0046] ① Add 153.5 grams (1 mole) of phosphorus oxychloride to the reaction device (mainly including reaction bottle, stirring device, dropping device, heating temperature control and gas absorption device), and then dropwise add 94 grams of pre-melted phenol (1 mole ), the total dropping time is about 1 hour. After the dropping is completed, react at 70-80°C for 2 hours. During this period, introduce the generated hydrogen chloride into the absorption device equipped with water until the concentration of hydrochloric acid no longer increases;

[0047] ② Slowly add 68.2 grams of ethylene glycol (1.1 moles) into the kettle, dropwise for 0.25 hours, control the temperature of the material at 80-90°C and continue the reaction for 2 hours, during which the generated hydrogen chloride is introduced into the absorption device filled with water , until the concentration of hydrochloric acid no longer i...

Embodiment 2

[0050] Embodiment 2: the preparation of organophosphate of the present invention

[0051]① Add 153.5 grams (1 mole) of phosphorus oxychloride to the reaction device (mainly including reaction bottle, stirring device, dropping device, heating and temperature control temperature gas absorption device), and dropwise add 108.1 grams of benzyl alcohol (1 mole). The dropping time is 2 hours. After the dropping is completed, react at 30-40°C for 1 hour, and introduce the generated hydrogen chloride into an absorption device equipped with water until the concentration of hydrochloric acid does not increase any more;

[0052] ② Slowly add 68.2 grams of ethylene glycol (1.1 moles) into the kettle, dropwise for 0.5 hours, control the temperature of the material at 80-90°C and continue the reaction for 2 hours, during which the generated hydrogen chloride is introduced into the absorption device filled with water , until the concentration of hydrochloric acid no longer increases;

[0053...

Embodiment 3

[0055] Embodiment 3: the preparation of organophosphate of the present invention

[0056] ① First add 153.5 grams (1 mole) of phosphorus oxychloride to the reaction device (mainly including reaction flask, stirring device, dropping device, heating and temperature control and gas absorption device), and drop 130.2 grams of octanol (1 mole), The total dropping time is 3 hours. After the dropping is completed, react at 30-40°C for 1.5 hours. During this period, introduce the generated hydrogen chloride into the absorption device equipped with water until the concentration of hydrochloric acid no longer increases;

[0057] ② Then slowly add 152.2 grams of 1,2-propanediol (2 moles) into the kettle, dropwise for 0.75 hours, control the temperature of the material at 80-90°C and continue the reaction for 1 hour, during which time the generated hydrogen chloride is introduced into the tank filled with water absorption device until the concentration of hydrochloric acid no longer incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com