Water-based fluoropolymer and silicon dioxide hybrid material and transparent super-amphiphobic coating prepared from same

A technology of silica and hybrid materials, applied in coating and other directions, can solve the problems of not very transparent super-amphiphobic materials, affecting the application of super-amphiphobic materials, easy agglomeration of silica, etc. The synthesis method is simple and the construction industry is environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

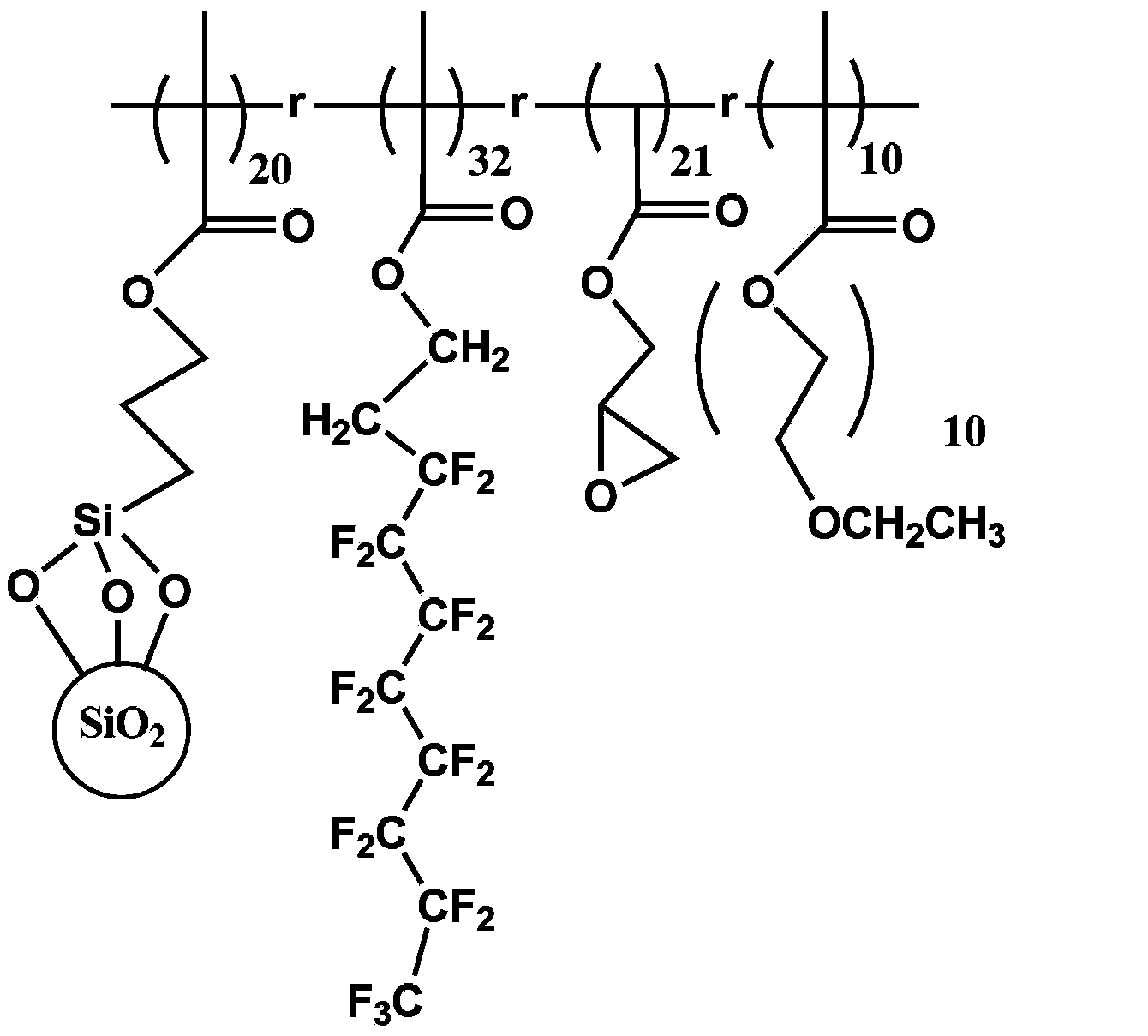

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

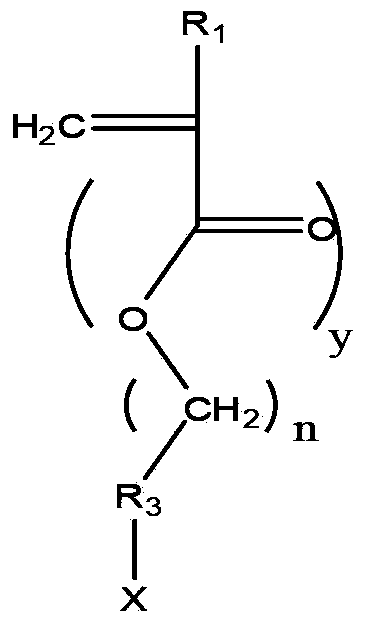

[0042] (1) Synthesize the cross-linkable water-dispersible fluoropolymer grafted on the surface by free radical polymerization. The specific synthesis process is: graft 0.1g of silica with double bonds on the surface (refer to the synthesis method: Research on Surface Modification of Nano-Silicon Dioxide by Silane Coupling Agent KH-570, Nanotechnology. Issue 3, 2009, Liu Qi, Cui Haixin, Gu Wei, Lin Chunmei, Li Ying), 1.2g monomer trimethacrylate Fluoroethyl ester, 0.8 glycidyl methacrylate, 1.01 polyethylene glycol methyl methacrylate, 0.0012g initiator (azobisisobutyronitrile AIBN) were added to 20mL toluene, after oxygen removal, the temperature was raised to After reacting for 24 hours at 80 degrees Celsius, the sample was taken out, centrifuged again, washed with ethanol for 3 times and then dried to finally obtain a water-based fluoropolymer and silicon dioxide hybrid material. Its structural formula is as follows:

[0043]

[0044] (2) Construction of transparent sup...

Embodiment 2

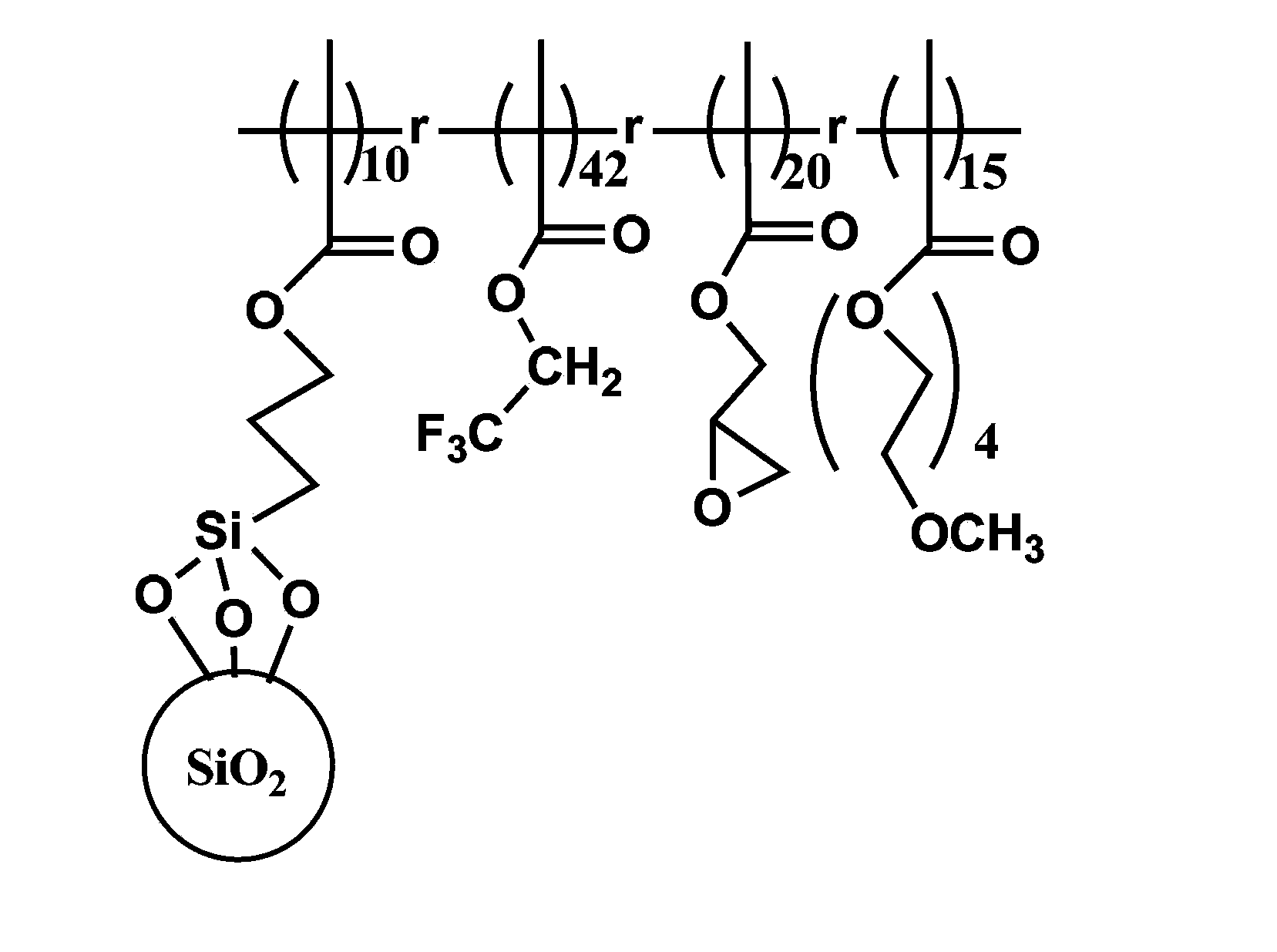

[0046] (1) Synthesize the cross-linkable water-dispersible fluoropolymer grafted on the surface by free radical polymerization. The specific synthesis process is: graft 0.25g of silica with double bonds on the surface (refer to the synthesis method: Research on Surface Modification of Nano-SiO2 by Silane Coupling Agent KH-570, Nanotechnology. Issue 3, 2009, Liu Qi, Cui Haixin, Gu Wei, Lin Chunmei, Li Ying), 5.2g perfluorooctylethyl Methacrylate, 2.01g propenyl glycidyl ether, 5.8g polyethylene glycol methyl methacrylate, 0.0032g initiator (azobisisobutyronitrile AIBN) were added to 50mL trifluorotoluene, after deoxygenation, After raising the temperature to 85 degrees Celsius and reacting for 20 hours, the sample was taken out, centrifuged again, washed with ethanol for 3 times, and then dried to finally obtain a water-based fluoropolymer and silica hybrid material. Its structural formula is as follows:

[0047]

[0048] (2) Construction of transparent super-amphiphobic co...

Embodiment 3

[0050] (1) Synthesize the cross-linkable water-dispersible fluoropolymer grafted on the surface by free radical polymerization. The specific synthesis process is: graft 0.25g of silica with double bonds on the surface (refer to the synthesis method: Research on Surface Modification of Nano-SiO2 by Silane Coupling Agent KH-570, Nanotechnology. Issue 3, 2009, Liu Qi, Cui Haixin, Gu Wei, Lin Chunmei, Li Ying), 3.2g perfluorooctylethyl Acrylates, 2.22 g 1,2-epoxy-5-hexene, 2.8 g polyethylene glycol methacrylate (n=6), 0.0032 g initiator (benzoyl peroxide BPO) were added to 50 mL trifluoro In toluene, after deoxygenation, the temperature was raised to 85 degrees Celsius, and after 18 hours of reaction, the sample was taken out, centrifuged, washed with ethanol three times, and then dried to finally obtain a water-based fluoropolymer and silica hybrid material. Its structural formula is as follows:

[0051]

[0052] (2) Construction of transparent super-amphiphobic coating: Diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com