Large crystal grain niobium material superconducting cavity and its manufacturing method

A superconducting cavity, large grain technology, applied in accelerators, electrical components, etc., can solve the problems of complex manufacturing process and high cost, and achieve the effect of improving microwave performance, ensuring quality, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The large-grain niobium material superconducting cavity proposed by the present invention and its manufacturing method are described in detail in conjunction with the accompanying drawings and embodiments as follows:

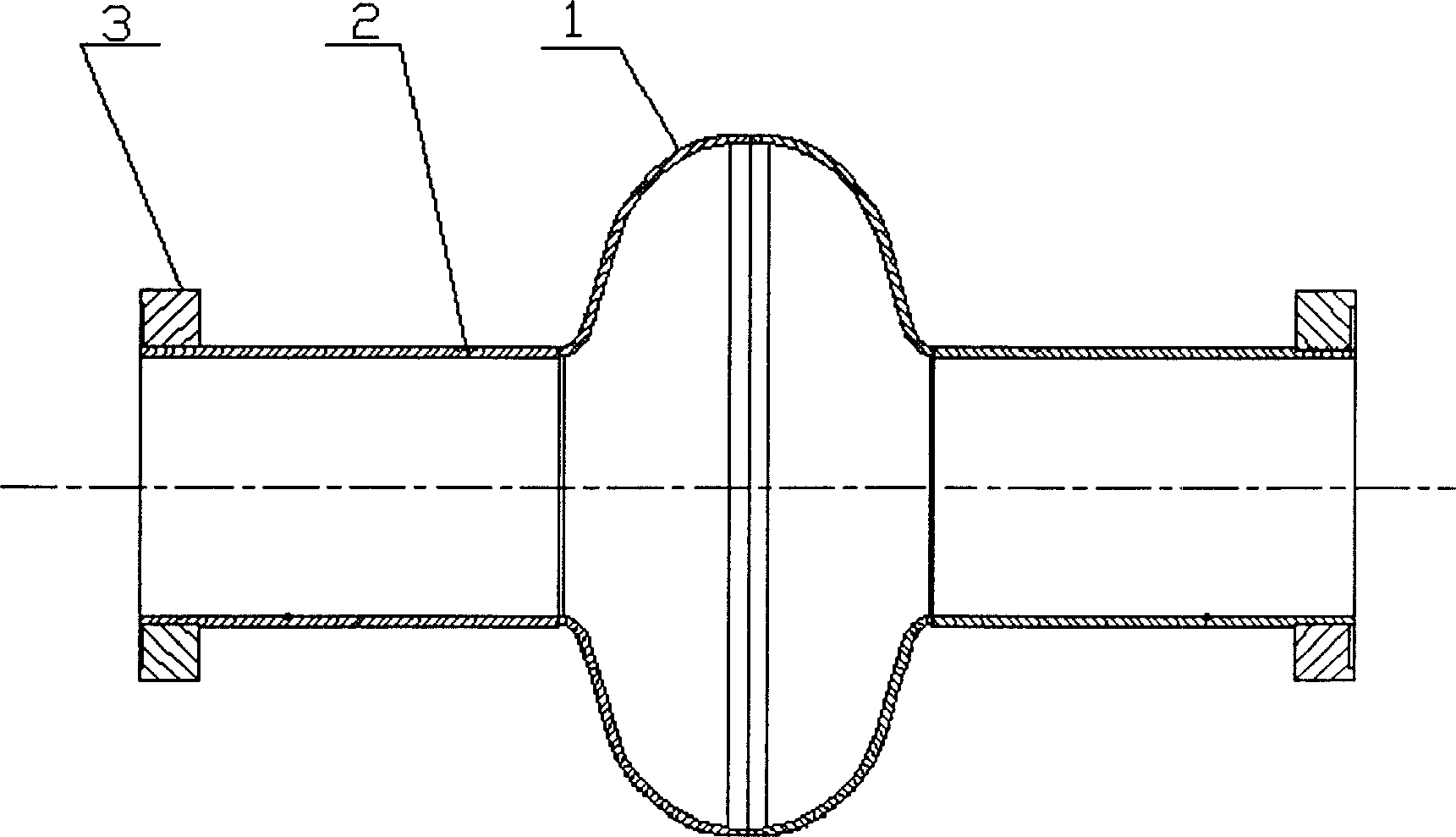

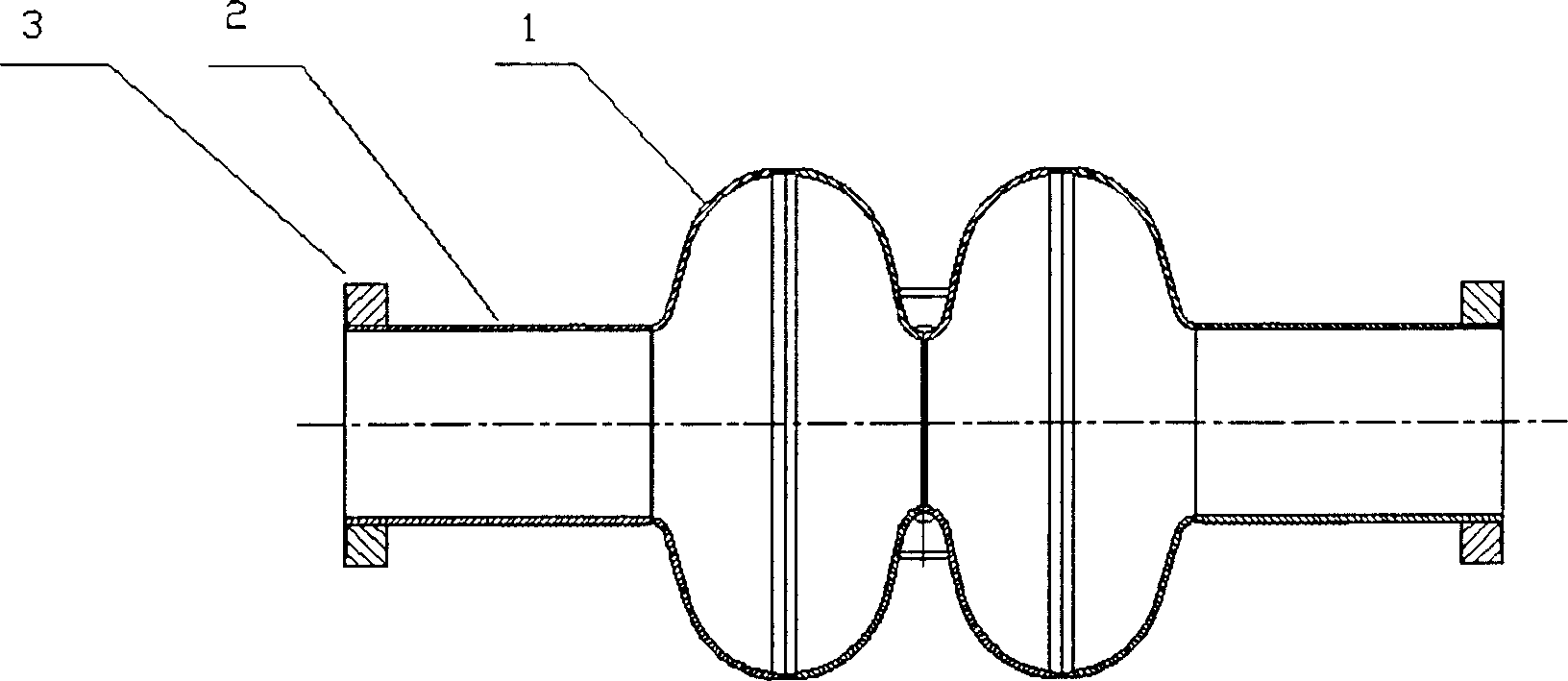

[0046] The present invention adopts the superconducting cavity embodiment with a frequency of 1.5ZHz made of large-grain niobium material, and its structure is as follows figure 1 shown. It includes an elliptical cavity 1 with a long diameter of 210mm and a short diameter of 114mm, and the opening diameter at both ends of the short diameter is 70mm. There are many large crystal grains distributed in the niobium wall plate of the oval niobium cavity, each Each grain diameter ranges between 5-7cm. A niobium round tube (bundle tube) 2 with a diameter of 70mm and a length of 110mm is connected to the two ports of the cavity, and the other end of each round tube is connected with a niobium-titanium alloy flange. The inner hole of the flange is 70mm, and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com