Nano-silver inkjet conductive ink subjected to low-temperature post-treatment and stabilization, and preparation method

A conductive ink and nano-silver technology, used in inks, household appliances, applications, etc., can solve the problems of increasing the temperature of ink post-processing, and achieve the effect of simplifying the post-processing process, overcoming the low stability and improving the dispersion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

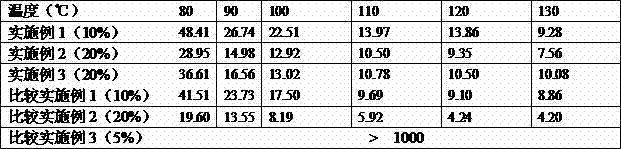

Examples

Embodiment 1

[0019] 1. Preparation of nano-silver particles coated with organic protective agent on the surface

[0020] Dissolve 4.175g of silver acetate in 40 mL of toluene, heat up to 60°C and add 10.175g of dodecylamine under stirring, and add 0.0506g of dodecylmercaptan to the system after 5 minutes; Add 11.35g of 12% phenylhydrazine toluene solution to the system; stir at 60°C for 60min, then cool down to below 40°C, add 10mL of acetone and stir for 15min, then add 100mL of a mixture of acetone and methanol in equal volume , continue to stir for 15 minutes, and filter; the filter cake is repeatedly washed with acetone, and dried naturally, which is nano-silver particles coated with dodecylamine and dodecylmercaptan on the surface, and the particle size is 5nm.

[0021] Second, the modulation of nano-silver conductive ink

[0022] Add 0.5 g of silver nanoparticles coated with dodecylamine and dodecylmercaptan on the surface prepared in step 1 into a mixed solution of 1 mL of cyclohex...

Embodiment 2

[0024] 1. Preparation of nano-silver particles coated with organic protective agent on the surface

[0025] Dissolve 4.175g of silver acetate in 40 mL of toluene, heat up to 60°C and add 12.425g of tetradecylamine under stirring, and add 0.0506g of dodecyl mercaptan to the system after 5 minutes; Add 8.59g of 12% phenylhydrazine toluene solution to the system; stir and react at a constant temperature of 60°C for 90min, then cool down to below 40°C, add 10mL of acetone and stir for 30min, then add 100mL of a mixture of acetone and methanol in equal volume , continue to stir for 30 minutes, and filter; the filter cake is repeatedly washed with acetone, and dried naturally, which is nano-silver particles coated with dodecyl mercaptan and tetradecylamine, and the particle size is 5nm.

[0026] Second, the modulation of nano-silver conductive ink

[0027] Add 1.0 g of silver nanoparticles coated with dodecylmercaptan and tetradecylamine on the surface prepared in step 1 into a mix...

Embodiment 3

[0029] 1. Preparation of nano-silver particles coated with organic protective agent on the surface

[0030] Dissolve 4.175g of silver acetate in 40 mL of toluene, heat up to 60°C and add 10.175g of dodecylamine while stirring, add 0.0753g of hexanethiol to the system after 5 minutes; continue to add to the system after 5 minutes 15.68g of phenylhydrazine toluene solution with a concentration of 8% by mass; Stir and react at a constant temperature of 60°C for 90min, then cool down to below 40°C, add 10mL of acetone and stir for 15min, then add 100mL of a mixture of acetone and methanol in equal volume, and continue stirring After 15 minutes, filter; the filter cake was repeatedly washed with acetone, and dried naturally, which was nano-silver particles coated with hexanethiol and dodecylamine on the surface, with a particle size of 5 nm.

[0031] Second, the modulation of nano-silver conductive ink

[0032] Add 1mL cyclohexane, the mixed solution of 0.5mL n-dodecane and 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com