Anti-aging polystyrene plastic product

A polystyrene plastic, polystyrene technology, applied in the field of daily necessities, can solve the problems of shortened service life, failure to meet the requirements of actual use, aging and brittleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

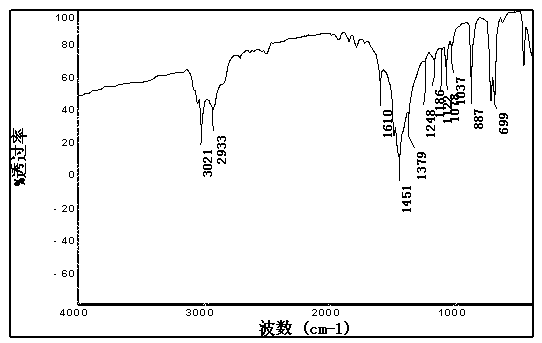

Image

Examples

Embodiment 1

[0024] The components of an anti-aging polystyrene plastic product include: 100Kg polystyrene, 10Kg ethyl methacrylate, 3Kg polyethylene terephthalate, 0.5Kg organic rare earth composite stabilizer, 2Kg stearyl benzene Formylmethane, 0.1Kg 4-acetylphenyl potassium sulfate, 4Kg silicon carbide fiber, 3Kg titanium dioxide, 1Kg calcium carbonate, 0.1Kg coupling agent, 4Kg toughening agent, 2Kg lubricant.

[0025] Described a kind of anti-aging polystyrene plastic product is processed according to the following method:

[0026] Add silicon carbide fiber, titanium dioxide, and calcium carbonate into the mixing kettle, mix evenly, then add organic rare earth composite stabilizer, coupling agent, toughening agent and lubricant, continue to stir and mix evenly; then add other materials, stir 10 minutes to mix well and evenly to obtain the mixture; then use a twin-screw extruder to extrude and granulate, and use an injection molding machine to form the particles at an injection molding...

Embodiment 2

[0035] The components of an anti-aging polystyrene plastic product include: 110Kg polystyrene, 13Kg ethyl methacrylate, 8Kg polyethylene terephthalate, 2Kg organic rare earth composite stabilizer, 5Kg stearoyl benzo Acyl methane, 0.4Kg 4-acetylphenyl potassium sulfate, 6Kg silicon carbide fiber, 7Kg titanium dioxide, 3Kg calcium carbonate, 0.3Kg coupling agent, 7Kg toughening agent, 5Kg lubricant.

[0036] Described a kind of anti-aging polystyrene plastic product is processed according to the following method:

[0037] Add silicon carbide fiber, titanium dioxide, and calcium carbonate into the mixing kettle, mix evenly, then add organic rare earth composite stabilizer, coupling agent, toughening agent and lubricant, continue to stir and mix evenly; then add other materials, stir Mix well for 15 minutes to obtain a mixture; then use a twin-screw extruder to extrude and granulate, and use an injection molding machine to process the resulting particles at an injection molding te...

Embodiment 3

[0046] The components of an anti-aging polystyrene plastic product include: 120Kg polystyrene, 15Kg ethyl methacrylate, 12Kg polyethylene terephthalate, 4Kg organic rare earth composite stabilizer, 7Kg stearoyl benzoate Acyl methane, 0.8Kg 4-acetylphenyl potassium sulfate, 8Kg silicon carbide fiber, 10Kg titanium dioxide, 5Kg calcium carbonate, 0.5Kg coupling agent, 9Kg toughening agent, 7Kg lubricant.

[0047] Described a kind of anti-aging polystyrene plastic product is processed according to the following method:

[0048] Add silicon carbide fiber, titanium dioxide, and calcium carbonate into the mixing kettle, mix evenly, then add organic rare earth composite stabilizer, coupling agent, toughening agent and lubricant, continue to stir and mix evenly; then add other materials, stir After 20 minutes, mix thoroughly and evenly to obtain the mixture; then use a twin-screw extruder to extrude and granulate, and use an injection molding machine to process the resulting particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com