Method of preparing composite micro-ecological powder for feed through flash evaporation and drying

A compound micro-ecology, flash drying technology, applied in animal feed, animal feed, application, etc., can solve the problems of large investment in equipment, affecting compounding effect, uneven mixing, etc., to reduce production costs, improve compounding effect, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

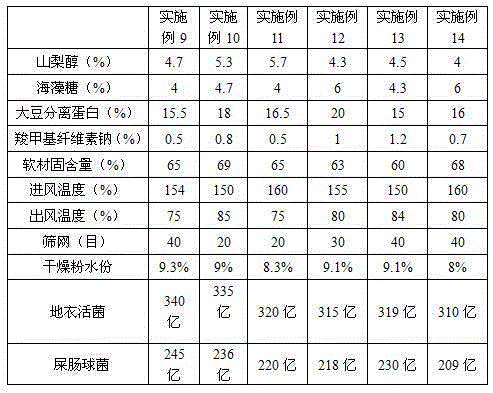

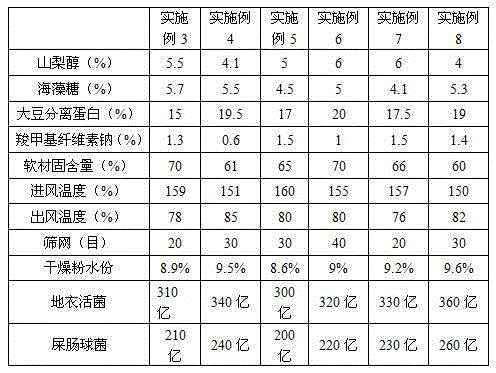

Examples

Embodiment 1

[0015] A method for flash drying and preparing compound microecological powder for feed, comprising the following steps:

[0016] (1) Prepare Bacillus licheniformis and Enterococcus faecium concentrates by liquid fermentation according to conventional methods;

[0017] (2) Mix the bacterial concentrate in step (1) according to the quality of 1:1; the solid content of the mixed bacterial concentrate is about 10%;

[0018] (3) Add the mixed bacterial solution obtained in step (2) to 4-6% sorbitol, 4-6% trehalose, 15-20% soybean protein isolate, 0.5-1.5% carboxymethyl cellulose Sodium plain, plus 16-36% corn starch to make a soft material with a solid content of 60-70%;

[0019] (4) Install the 20-40 mesh screen of the flash drying equipment as required, turn on the flash drying equipment, adjust the inlet air temperature to 150-160°C, and the outlet air temperature to 75-85°C; (3) The obtained soft material is added to a flash drying tower to obtain a composite microecological...

Embodiment 2

[0022] A method for flash drying and preparing compound microecological powder for feed, comprising the following steps:

[0023] (1) Prepare Bacillus licheniformis and Enterococcus faecium concentrates by liquid fermentation according to conventional methods;

[0024] (2) Mix the bacterial concentrate in step (1) evenly at a mass ratio of 1:1; the solid content in the mixed bacterial concentrate is 11%;

[0025] (3) Add 5% sorbitol, 5% trehalose, 18% soybean protein isolate, 1% sodium carboxymethyl cellulose, and 25% corn starch to the mixed bacterial solution obtained in step (2) to make a solid content 65% soft material;

[0026] (4) Install the 30-mesh screen of the flash drying equipment as required, turn on the flash drying equipment, adjust the inlet air temperature to 150°C, and the outlet air temperature to 80°C; use the screw feeder to feed the soft materials into the flash drying tower to obtain composite micro-ecological powder.

[0027] The moisture content of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com