Anti-oxidation polyethylene heat shrinkable film with high tensile strength and preparing method thereof

A technology of high tensile strength and heat-shrinkable film, which is applied in the field of heat-shrinkable film, can solve problems such as easy aging and cracking, low tensile strength, and failure to meet requirements, and achieve good anti-aging performance, good formability, and improved heat shrinkage. The effect of sealing and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

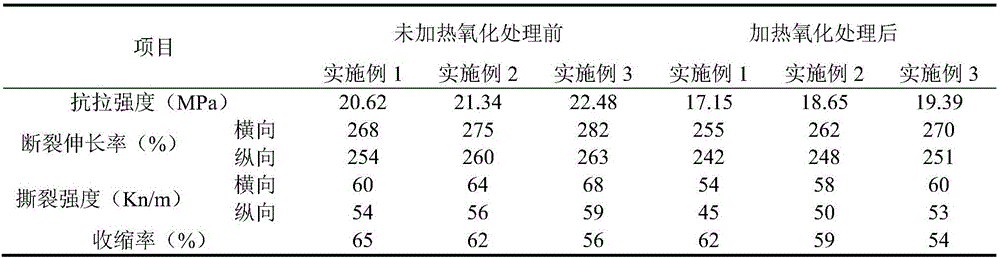

Examples

Embodiment 1

[0021] An anti-oxidation high tensile strength polyethylene heat-shrinkable film, which consists of the following components in parts by weight: 60 parts of metallocene linear low-density polyethylene, 30 parts of ethylene-octene copolymer, 10 parts of nano-titanium dioxide, epoxy sunflower 6 parts of seed oil, 4 parts of oleic acid amide, 3 parts of magnesium hydroxide, 2 parts of licorice, 2 parts of antioxidant 1010, 1 part of heat stabilizer.

[0022] Preferably, the nano titanium dioxide is rutile nano titanium dioxide with a diameter of 50nm;

[0023] A kind of anti-oxidation high tensile strength polyethylene heat-shrinkable film of the present invention, its preparation method comprises the following steps:

[0024] (1) take each raw material according to the formula weight part;

[0025] (2) 100 parts of licorice are pulverized to 80 mesh with a pulverizer, and then 200 parts of deionized water are added, stirred and mixed evenly to obtain a mixed solution, which is ...

Embodiment 2

[0030] An anti-oxidation high tensile strength polyethylene heat-shrinkable film, which consists of the following components in parts by weight: 80 parts of metallocene linear low-density polyethylene, 40 parts of ethylene-octene copolymer, 35 parts of licorice, and 20 parts of nano-titanium dioxide , 10 parts of epoxy soybean oil, 6 parts of oleic acid amide, 5 parts of magnesium hydroxide, 3 parts of antioxidant 168, 2 parts of heat stabilizer;

[0031] Preferably, the nano titanium dioxide is rutile nano titanium dioxide with a diameter of 50nm;

[0032] A kind of anti-oxidation high tensile strength polyethylene heat-shrinkable film of the present invention, its preparation method comprises the following steps:

[0033] (1) take each raw material according to the formula weight part;

[0034] (2) 100 parts of licorice are pulverized to 80 mesh with a pulverizer, and then 200 parts of deionized water are added, stirred and mixed evenly to obtain a mixed solution, which is ...

Embodiment 3

[0039] An anti-oxidation high tensile strength polyethylene heat-shrinkable film, which is composed of the following components in parts by weight: 70 parts of metallocene linear low-density polyethylene, 35 parts of ethylene-octene copolymer, 30 parts of licorice, and 15 parts of nano-titanium dioxide , 8 parts of epoxy soybean oil, 5 parts of oleic acid amide, 4 parts of magnesium hydroxide, 2.5 parts of antioxidant, 1.5 parts of heat stabilizer;

[0040] Preferably, the nano titanium dioxide is rutile nano titanium dioxide with a diameter of 50nm;

[0041] Preferably, the antioxidant is a composite antioxidant of antioxidant 1010 and antioxidant 168, with a weight ratio of 1:1;

[0042] A kind of anti-oxidation high tensile strength polyethylene heat-shrinkable film of the present invention, its preparation method comprises the following steps:

[0043] (1) take each raw material according to the formula weight part;

[0044] (2) 100 parts of licorice are pulverized to 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com