Three-layer ethylene vinyl acetate copolymer negative pressure casting film and preparation method thereof

A technology of ethylene vinyl acetate copolymer and ethylene vinyl acetate, which can be used in casting and molding equipment, chemical instruments and methods, layered products, etc., and can solve problems such as easy breakage and stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

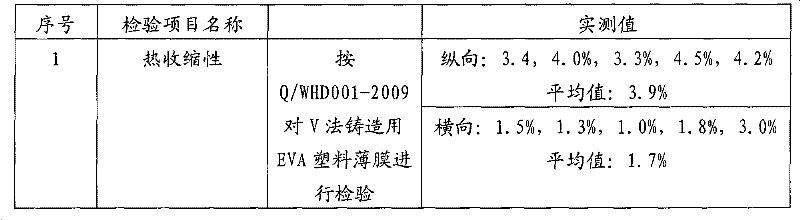

Image

Examples

Embodiment 1

[0015] Add 60Kg of ethylene vinyl acetate copolymer with a molecular weight of 20,000 to 500,000, 13Kg of low-density polyethylene with a molecular weight of 200,000, and 60g of oleic acid amide into three mixing bodies according to the materials used in the upper, middle, and lower layers. Add the ethylene vinyl acetate copolymer of 6.5Kg low-density polyethylene, 30g oleic acid amide and 5Kg respectively in the stirring body of the lower layer of materials, and the remaining 50Kg of ethylene vinyl acetate copolymer is added into the stirring body of the middle layer of materials, Fully mix, and then suck it into the discharge port of the extruder through the suction machine, the three extruders move in the same direction, and gather at the upper end of the die in three different flow channels to form a three-layer affinity The integrated liquefied body is blown by air, shaped, cooled and shaped to produce a three-layer composite negative pressure casting film of ethylene viny...

Embodiment 2

[0017] Add 80Kg of vinyl acetate copolymer with a molecular weight of 20,000 to 500,000, 10Kg of low-density polyethylene with a molecular weight of 200,000, and 50g of oleic acid amide into three mixing bodies according to the materials used in the upper, middle and lower layers. Add 5Kg of low-density polyethylene, 25g of oleic acid amide and 5Kg of vinyl acetate copolymer to the mixing body of the material for the lower layer, and add the remaining 70Kg of ethylene vinyl acetate copolymer to the mixing body of the material for the middle layer, and fully stir Then they are sucked into the discharge port of the extruder through the suction machine respectively. The three extruders move in the same direction and gather at the upper end of the die in three different flow channels to form a three-layer affinity integrated liquefaction The body is blown by air, shaped, cooled, and formed to obtain a three-layer composite negative pressure casting film of ethylene vinyl acetate co...

Embodiment 3

[0019] Add 70Kg of ethylene vinyl acetate copolymer with a molecular weight of 20,000 to 500,000, 15Kg of low-density polyethylene with a molecular weight of 200,000, and 15g of oleic acid amide into three mixing bodies according to the materials used in the upper, middle and lower layers. Add 7.5Kg of low-density polyethylene, 7.5g of oleic acid amide and 7.5Kg of ethylene vinyl acetate copolymer to the mixing body of the material for the lower layer, and add the remaining 55Kg of ethylene vinyl acetate copolymer to the mixing body of the material for the middle layer Fully mixed, and then sucked into the discharge port of the extruder through the suction machine, the three extruders move in the same direction, and gather at the upper end of the die in three different flow channels to form three layers Affinity integrated liquefied body, after air inflation, shaping, cooling and forming, the three-layer composite negative pressure casting film of ethylene vinyl acetate copolym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com