A preparation method of modified polyester and its application in polyester film for dry film resist

A technology for modifying polyester and polyester film, which is applied in the field of polyester modification to achieve the effects of excellent antistatic properties, good mechanical strength and excellent antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

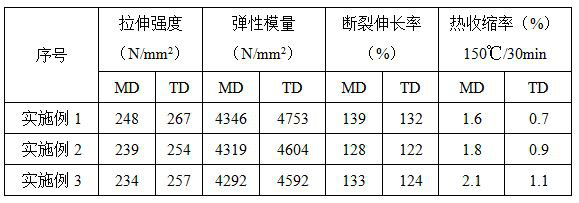

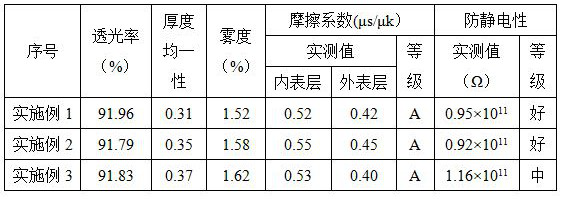

Embodiment 1

[0048] Example 1: A preparation method of modified polyester and its application in polyester film for dry film resist

[0049] Include the following steps:

[0050] 1. Preparation of polyester modified nano silica

[0051] Add 90 kg of titanate coupling agent ZJ-38S to 1000 kg of silica sol, stir at 18,000 rpm at high speed, heat to 55°C and react at a constant temperature for 2.5 hours. Wash with water and ethanol for 3 times, vacuum dry at 50°C and grind into 700-mesh white powder, slowly add 900 kg of white powder to 1620 kg of phenoxyethanol at a stirring rate of 23,000 rpm, stir for 40 minutes to disperse the powder evenly, and then Add 630 kg of hydroxyl-terminated hyperbranched polyester and 333 kg of p-toluenesulfonic acid, heat up to 110°C and react at a constant temperature for 1.2 hours. After the reaction is completed, high-speed centrifugation separates and obtains a white precipitate. After washing with water for 3 times, vacuum-dry at 80°C for 2 hours to obtai...

Embodiment 2

[0058] Example 2: A preparation method of modified polyester and its application in polyester film for dry film resist

[0059] Include the following steps:

[0060] 1. Preparation of polyester modified nano silica

[0061] Add 70 kg of titanate coupling agent ZJ-38S to 1000 kg of silica sol, stir at 15,000 rpm at high speed, heat to 50°C for 2 hours at a constant temperature and react for 2 hours. Wash with water and ethanol for 3 times, vacuum dry at 50°C and grind into 600-mesh white powder, slowly add 900 kg of white powder to 1440 kg of phenoxyethanol at a stirring rate of 20,000 rpm, stir for 30 minutes to disperse the powder evenly, and then Add 540 kg of hydroxyl-terminated hyperbranched polyester and 270 kg of p-toluenesulfonic acid, raise the temperature to 100°C and react at a constant temperature for 1 hour. After the reaction is completed, high-speed centrifugation separates and obtains a white precipitate. After washing 3 times with water, vacuum-dry at 80°C for...

Embodiment 3

[0068] Example 3: A preparation method of modified polyester and its application in polyester film for dry film resist

[0069] Include the following steps:

[0070] 1. Preparation of polyester modified nano silica

[0071] Add 110 kg of titanate coupling agent ZJ-38S to 1,000 kg of silica sol, stir at 20,000 rpm at high speed, heat to 65°C for 3 hours, and react at a constant temperature for 3 hours. Wash with water and ethanol for 3 times, vacuum dry at 50°C, and grind into 800-mesh white powder. Slowly add 900 kg of white powder to 1,800 kg of phenoxyethanol at a stirring rate of 25,000 rpm, stir for 45 minutes to disperse the powder evenly, and then Add 720 kg of hydroxyl-terminated hyperbranched polyester and 405 kg of p-toluenesulfonic acid, heat up to 120°C and react at a constant temperature for 1.5 hours. After the reaction is completed, high-speed centrifugation separates and obtains a white precipitate. After washing 3 times with water, dry at 80°C for 2 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com