Multifunctional corrosion inhibitor and preparing method thereof

A corrosion inhibitor, multifunctional technology, used in additives, petroleum industry, lubricating compositions, etc., can solve the problem of single function of corrosion inhibitor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for preparing iron, aluminum, copper and alloy corrosion inhibitor thereof:

[0038] Based on the total volume of the multifunctional buffer, add successively 9% by mass percent of tall oleic acid diethanolamide phosphate, 36% by mass percent of dodecenyl succinic anhydride diethanolamide lithium salt, and 38% by mass Tall oleic acid diethanolamide borate, 16% isomeric oleic acid amide by mass, 0.3% benzotriazole by mass, 0.5% sodium benzoate by mass, 0.2% by mass The sodium molybdate is fully stirred with a stirrer until uniformly mixed, and is marked as Example 1.

Embodiment 2

[0040] The method for preparing iron, aluminum, copper and alloy corrosion inhibitor thereof:

[0041] Based on the total volume of the multifunctional buffer, add successively 7% by mass of tall oleic acid diethanolamide phosphate, 35% by mass of dodecenyl succinic anhydride lithium salt of diethanolamide, and 40% by mass Tall oleic acid diethanolamide borate, isomeric oleic acid amide of 17% by mass, benzotriazole of 0.4% by mass, sodium benzoate of 0.4% by mass, 0.2% by mass The sodium molybdate is fully stirred with a stirrer until it is evenly mixed, and it is marked as Example 2.

Embodiment 3

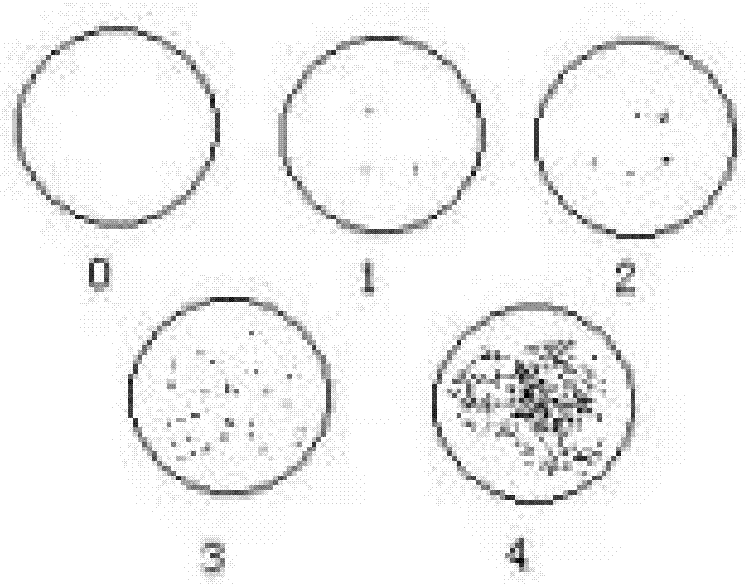

[0046] Referring to the corrosion test method in "GB6144-2010 Synthetic Cutting Fluid", the rust prevention and corrosion inhibition properties of cast iron, LY12 aluminum, red copper and brass H62 in Example 1, Example 2, Comparative Example 1 and Comparative Example 2 were tested.

[0047] 1. Configure working solution: respectively configure Example 1, Example 2, Comparative Example 1 and Comparative Example 2 (conventional corrosion inhibitor sodium silicate) into 0.5% corresponding working solution, wherein the solute in the working solution is the embodiment 1, embodiment 2, comparative example 1 and comparative example 2, solvent is tap water; Blank comparative example is tap water.

[0048] 2. Set the incubator to 55°C and preheat;

[0049] 3. After taking out the metal test piece, wash the anti-rust oil with absolute ethanol;

[0050] 4. After the metal test piece is dry, polish the surface with 400 mesh sandpaper so that there are no pits, scratches or rust on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com