Low pour point diesel fuel lubricity improver composition

A composition and lubricity technology, applied in the field of additives, can solve problems such as high freezing point, high processing cost, and inconvenient use

Inactive Publication Date: 2014-09-17

ZHONGHAI YABAO BEIJING TECH DEV

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, mainstream lubricity improvers have been widely used in major oil refineries all over the world. The main defect is that these lubricity improvers have a high freezing point. Before use, they need to be heated on site to make them liquefied, which is very uncomfortable to use. Convenience, especially in southern refineries, many do not have the conditions for heating additives, and there is an urgent need to use low freezing point diesel lubricity additives

At present, there are many literatures and patent reports to reduce the lubricity of diesel oil through the process, but because of the huge processing cost, there are few applications at present.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Login to View More

Abstract

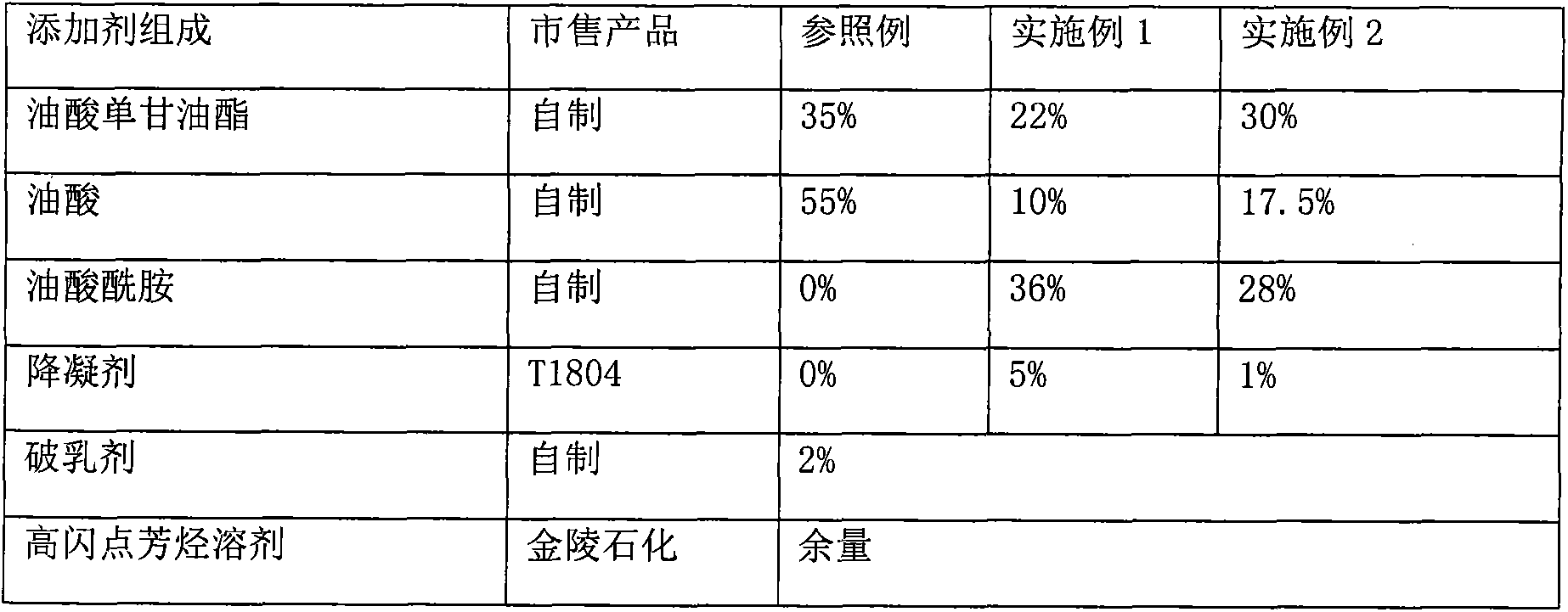

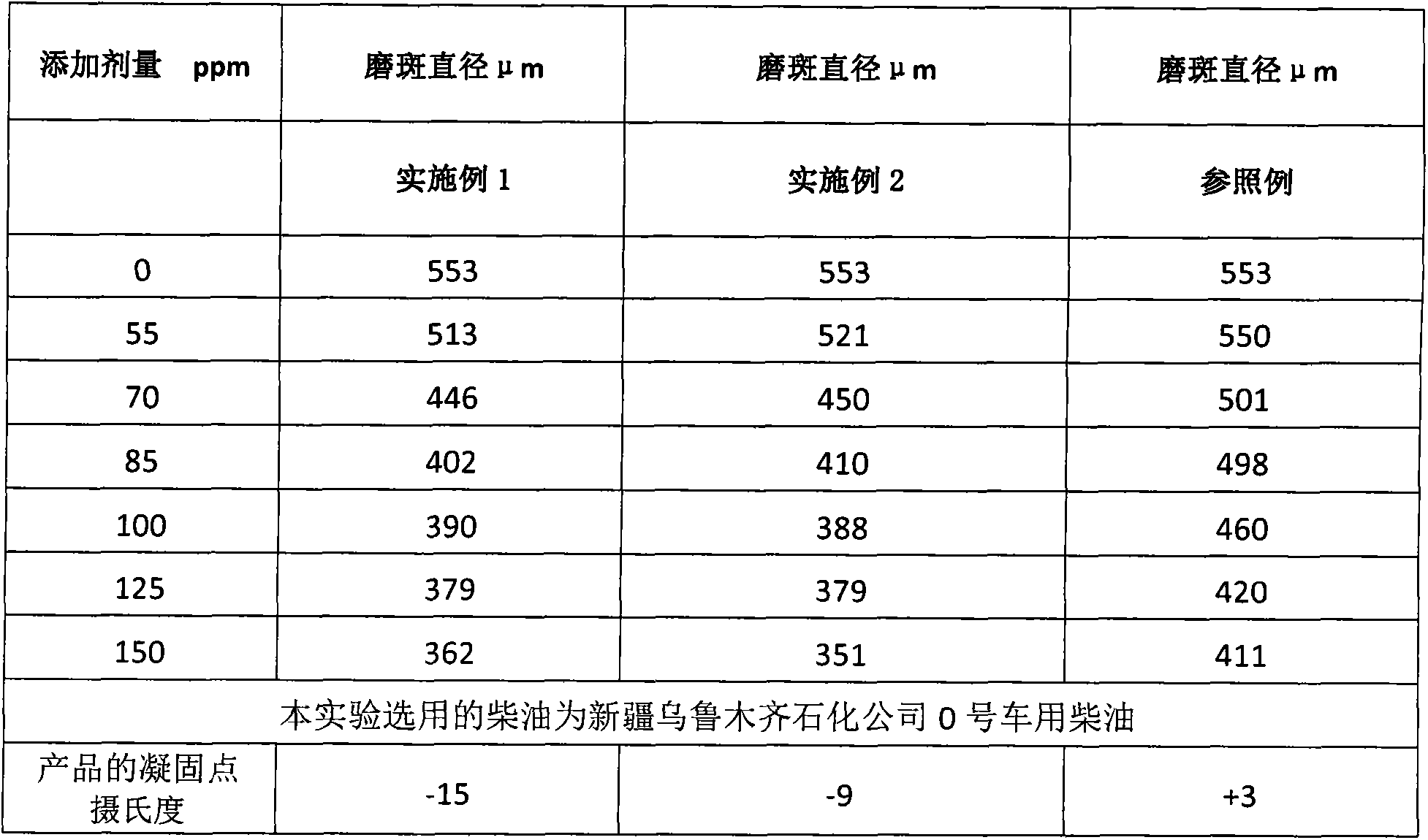

The invention discloses a low pour point diesel fuel lubricity improver composition prepared by compounding a pour point reducer with fatty acid, fatty acid ester and oleic acid amide and the like, and the solidifying point of the combination can be obviously reduced.

Description

technical field [0001] The invention belongs to the additive technology for improving the lubricity of low-sulfur diesel oil in the refining industry, in particular to a low-pour point diesel lubricity improver composition Background technique [0002] In order to further improve the atmospheric environment on which human beings depend and improve the quality of diesel engine exhaust emissions, domestic and foreign fuel oil production companies have begun to adopt deep processing and refining processes in recent years to produce low-sulfur diesel oil characterized by low sulfur content and low aromatic hydrocarbon content. Diesel engines burning low-sulfur diesel greatly reduce particulate matter (PM) emissions caused by sulfur elements and aromatic hydrocarbons, and greatly prolong the service life of exhaust gas catalysts. The ring form exists in aromatic hydrocarbons and polycyclic aromatic hydrocarbons, and the non-selective desulfurization process removes aromatic hydro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10L10/08

Inventor 张凯

Owner ZHONGHAI YABAO BEIJING TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com