Production and filling treatment method of antibacterial whitening active peptide toothpaste

A treatment method and technology of active peptides, applied in the directions of packaging, packaging protection, packaging sterilization, etc., can solve the problems of impact, cleaning out impurities in toothpaste tubes, cumbersome sterilization process of toothpaste tubes, etc., so as to avoid cumbersome processes, fix them conveniently, Avoid the effect of extrusion deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

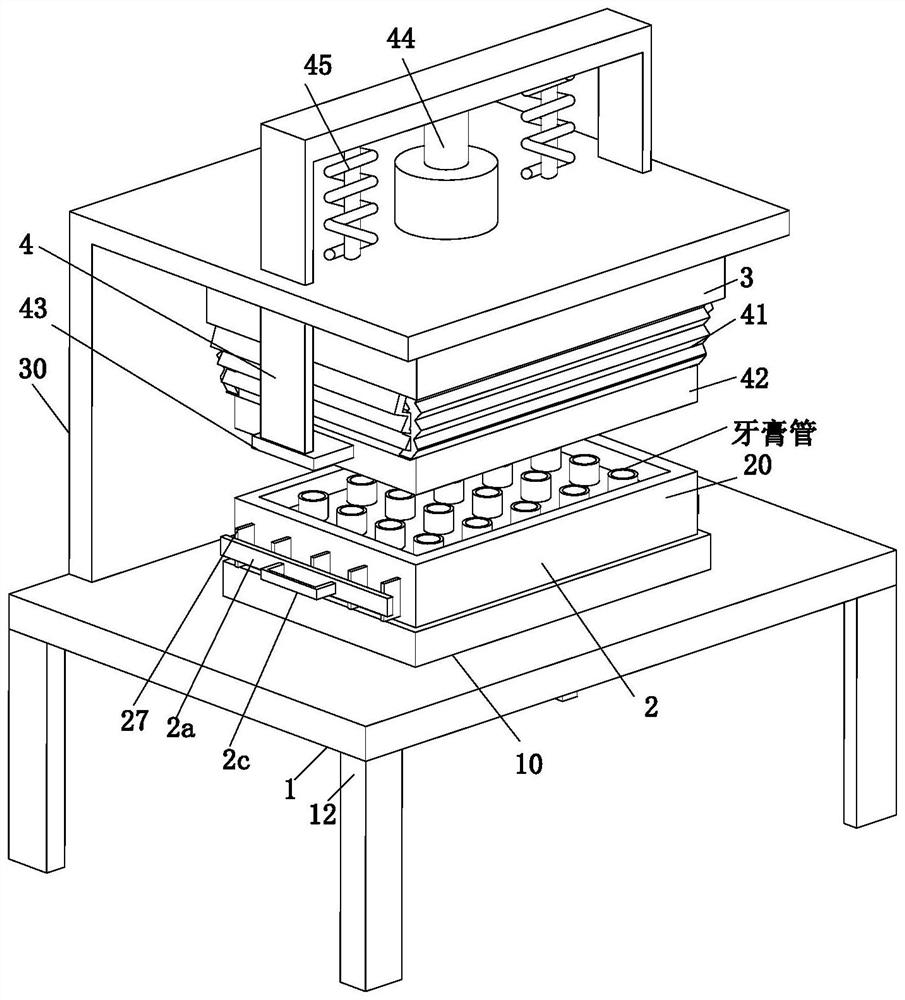

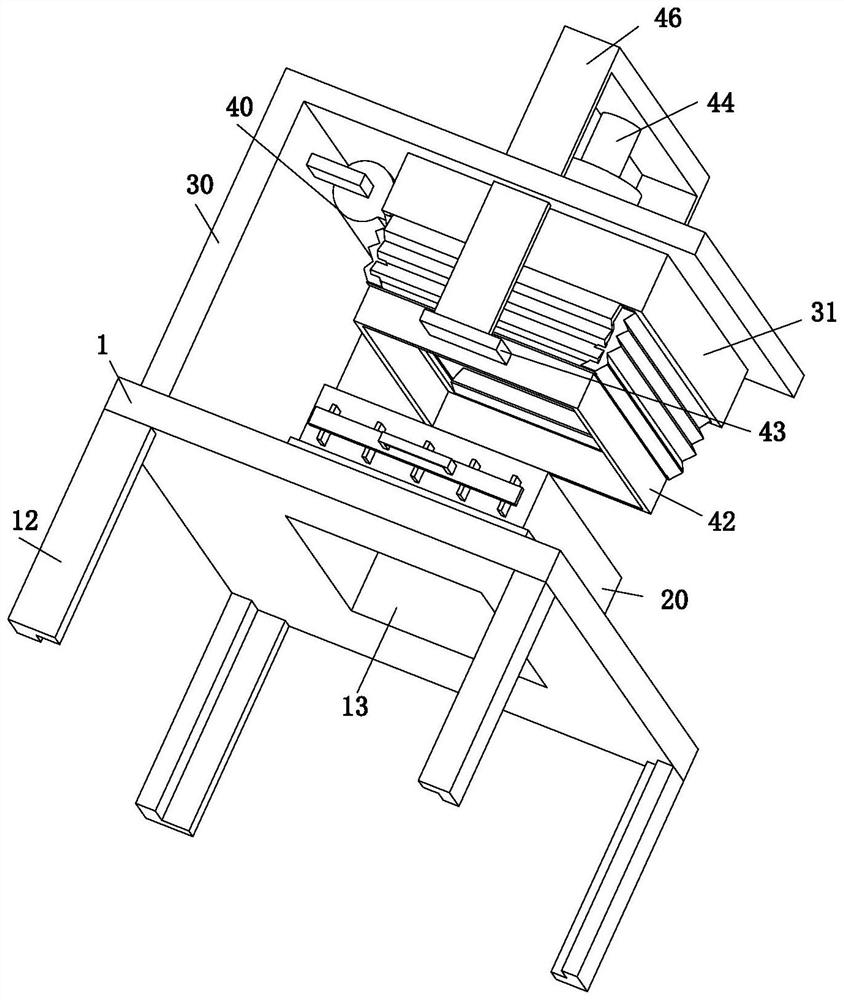

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

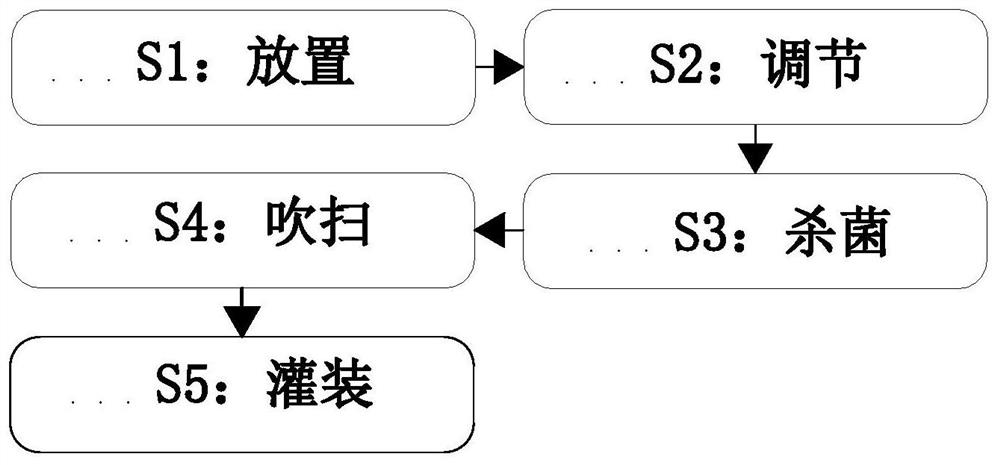

[0035] Such as Figure 1 to Figure 10Shown, a kind of antibacterial whitening active peptide toothpaste production filling processing method, it has used a kind of antibacterial whitening active peptide toothpaste production filling processing device, this antibacterial whitening active peptide toothpaste production filling processing device includes workbench 1 , fixed adjustment mechanism 2, sterilizing mechanism 3 and purging mechanism 4, adopt the above-mentioned antibacterial whitening active peptide toothpaste production filling treatment device to carry out the toothpaste production filling treatment method as follows:

[0036] S1. Placement: put the toothpaste tube after production into the storage box 20, and insert the outlet end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com