A grading and screening device for intelligent packaging design

A technology of grading screening and intelligent packaging, applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problems of reduced classification fineness, high production line cost, affecting processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

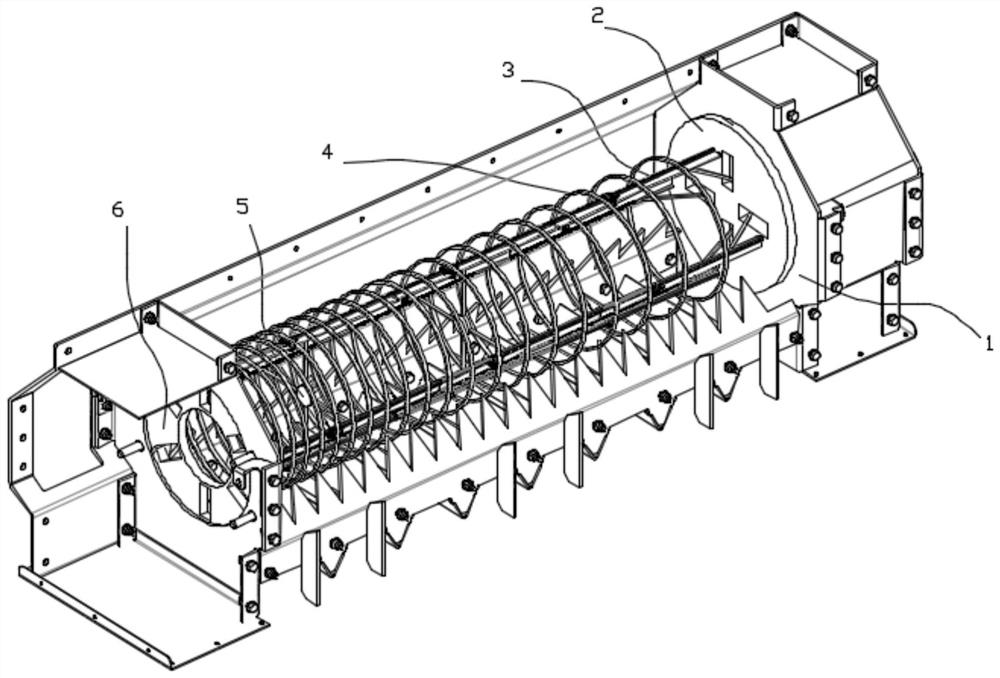

[0028] see figure 1 , in an embodiment of the present invention, a grading and screening device for intelligent packaging design, including a casing 1 and a guide rail assembly 3, the casing 1 has a long cylindrical cavity, and the bottom of the cavity is hollowed out, and the cavity The two ends are respectively rotatably provided with a concentric driving turntable 2 and a driven turntable 6, and the driven turntable 6 is vertically higher than the drive turntable 2;

[0029] There are many guide rail assemblies 3 whose two ends are respectively fixed on the surface of the active turntable 2 and the driven turntable 6, and the circumference of the drive turntable 2 and the driven turntable 6 is distributed. Each guide rail assembly 3 surrounds the inner spacer ring 4 , and the distance between the spacer rings 4 increases along the direction from the driven turntable 6 to the driving turntable 2 .

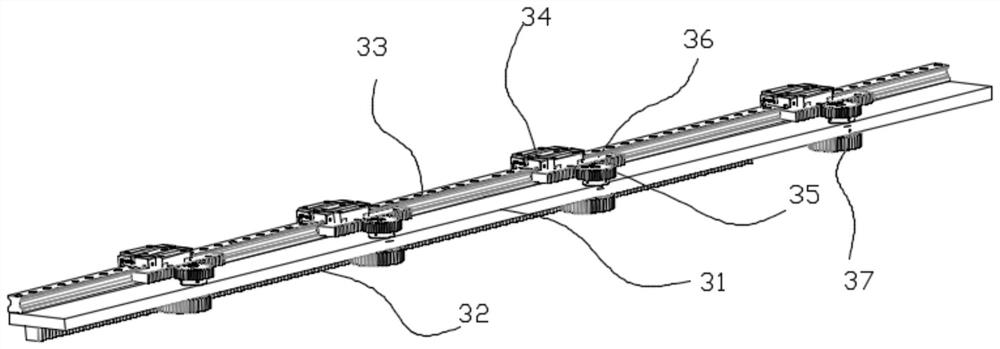

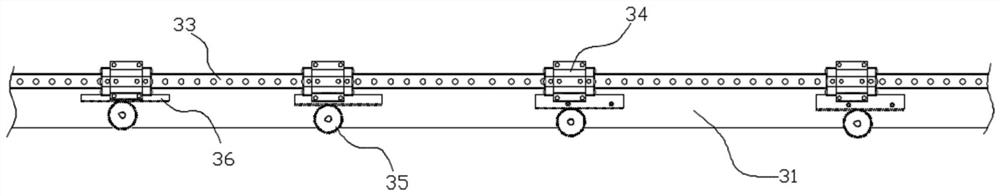

[0030] see figure 2 with image 3 , in this embodiment, the guide rail a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com