Centrifugal screening and grading device

A grading device and centrifugal technology, which is applied in the field of centrifugal screening and grading devices, can solve the problems of inaccurate screening, low application range of screening devices, and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

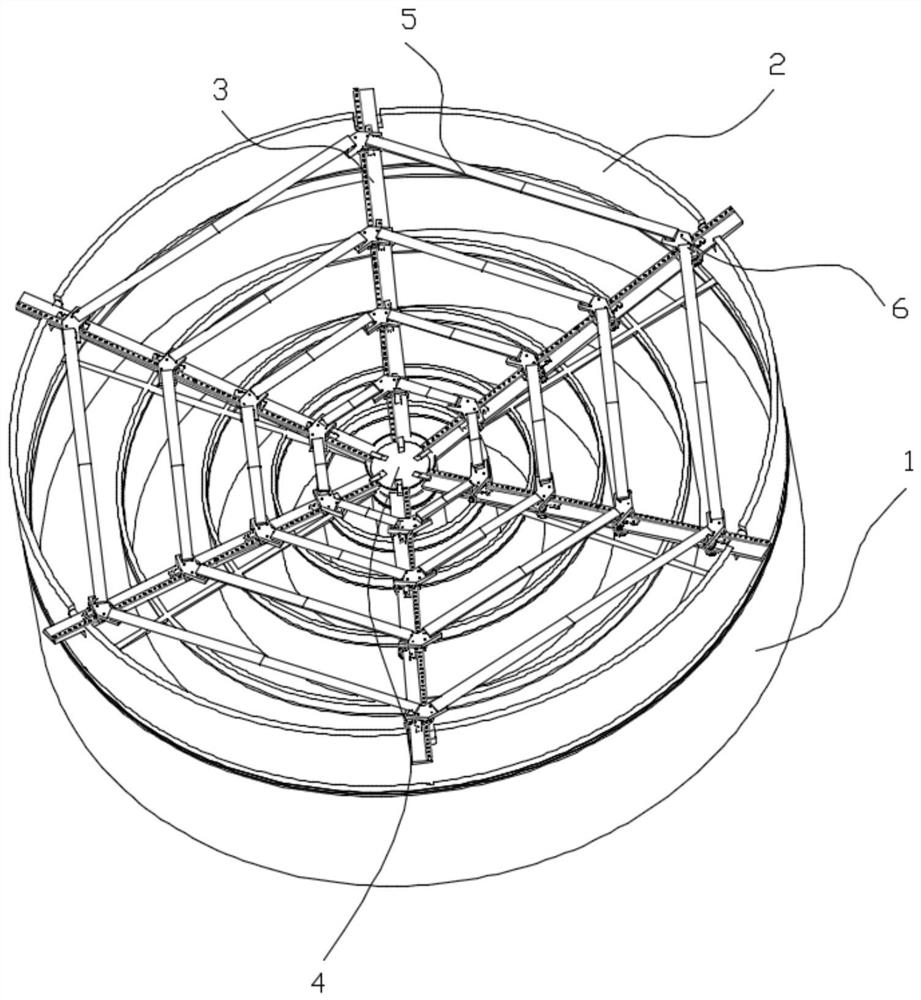

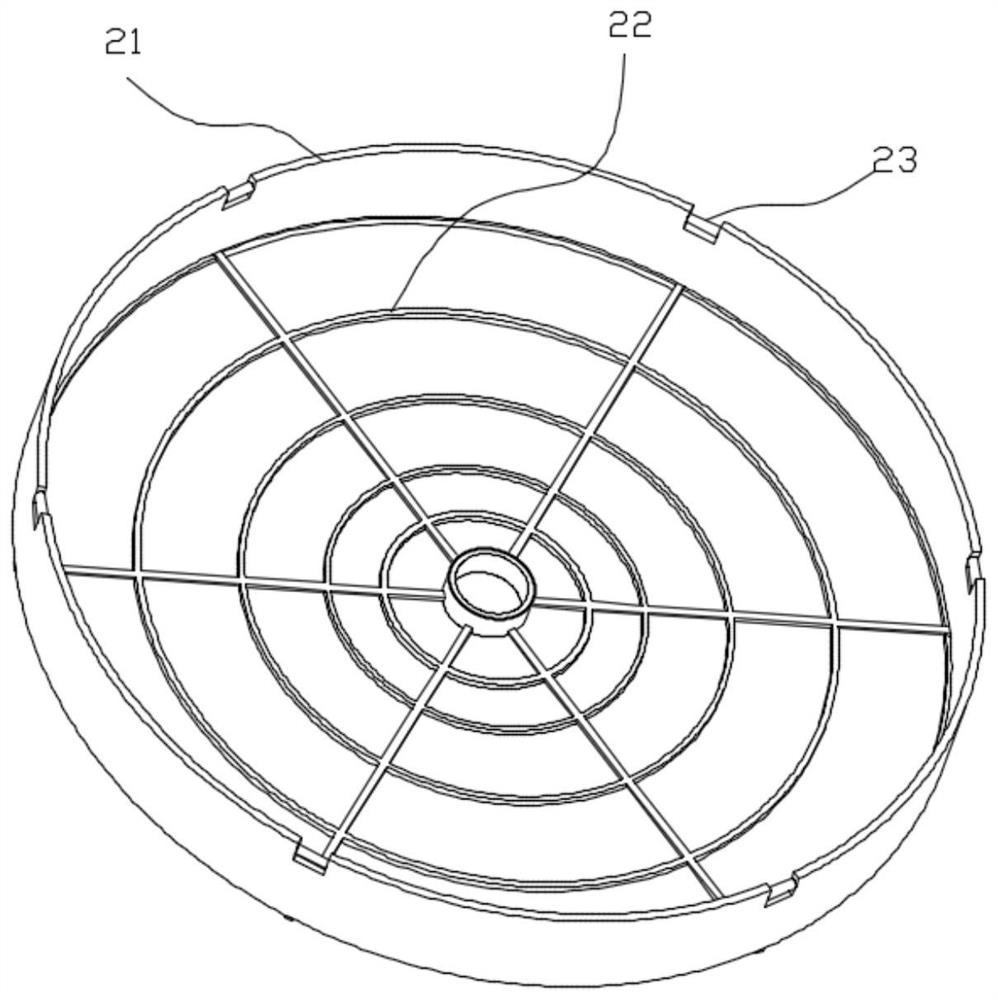

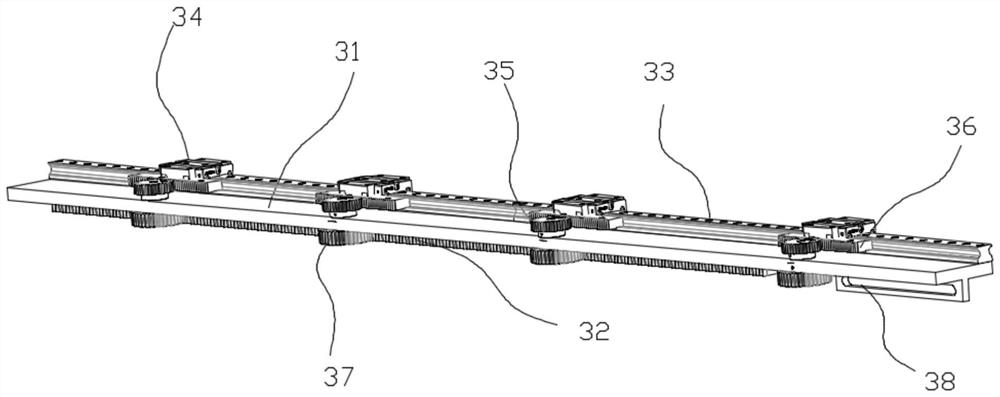

[0030] see figure 1 , in an embodiment of the present invention, a centrifugal screening and grading device includes a base 1 and a spoke rail assembly 3, wherein a turntable 2 is rotatably provided on the base 1, and a hinged disc 4 is provided at the center of the turntable 2, The edge of the articulated disc 4 is articulated with a plurality of spoke guide rail assemblies 3 along the diameter direction, each of the spoke guide rail assemblies 3 is movably provided with a plurality of spacer connecting seats 6, and the spacer bars on the same spoke guide rail assembly 3 are connected The distance between the seats 6 increases proportionally from the center of the circle to the outside;

[0031] Two adjacent spoke guide rail assemblies 3 are connected between spacer connecting seats 6 with the same distance from the center of the circle, and telescopic spacers 5 that can be changed in length are connected. 5 surrounded by a circle of polygons;

[0032] The base 1 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com