Automatic resetting multi-level-cylinder type track raising or shifting device

An automatic reset, multi-stage cylinder technology, used in roads, tracks, laying tracks, etc., can solve problems such as reducing the bearing capacity of hydraulic cylinders, and achieve the effect of improving work efficiency, reducing ownership and cost investment, and saving time intervals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

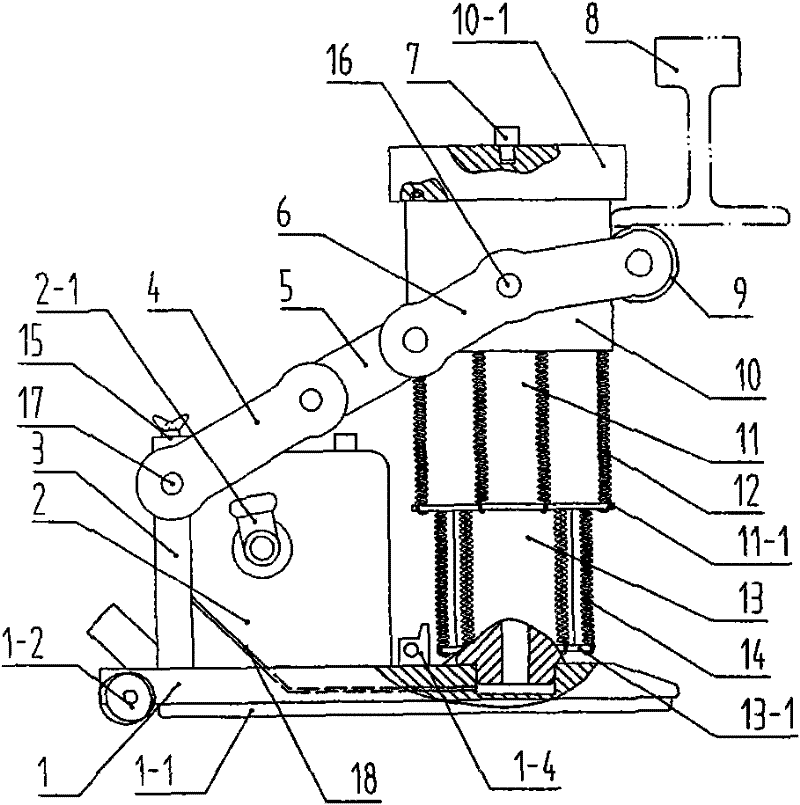

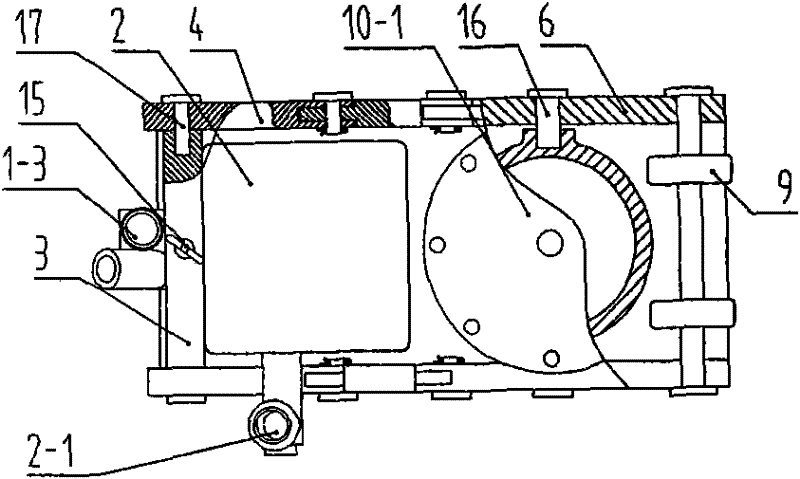

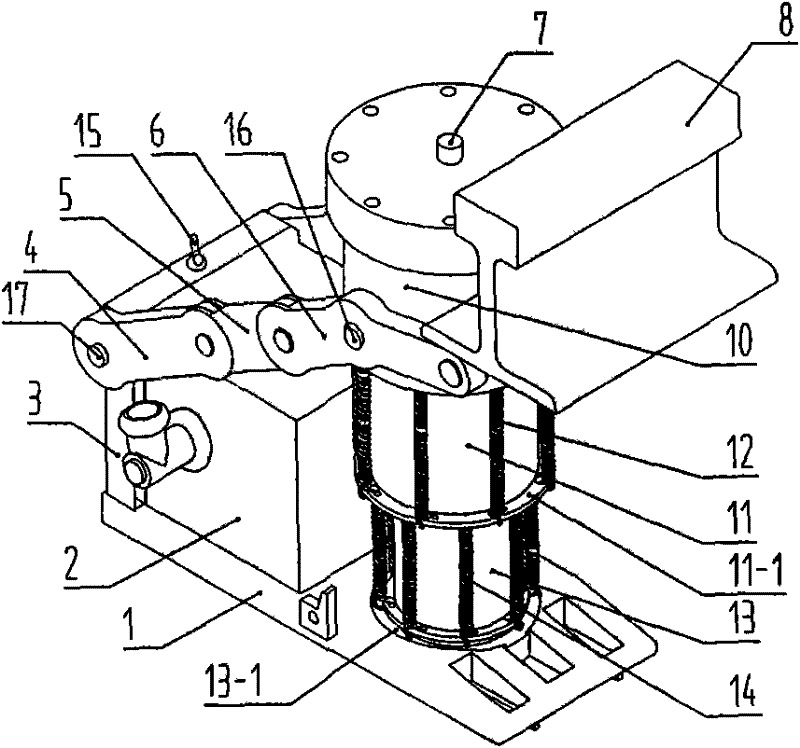

[0024] Such as figure 1 , figure 2 , image 3 As shown: an automatic reset multi-stage cylinder lifting device includes: a base 1, a hand pump assembly 2, a hydraulic cylinder, a lifting wheel 9 and a balance force frame connecting the hydraulic cylinder and the base 1; A pressure rod seat 2-1 is arranged on one side of the pump assembly 2; the characteristic is that the hydraulic cylinder is a multi-stage cylinder, and this embodiment is a two-stage cylinder, and a three-stage cylinder can also be used. The multi-stage cylinder is composed of a primary cylinder block 10, a secondary cylinder block 11, a piston rod 13 and a cylinder head 10-1, wherein the secondary cylinder block 11 doubles as the piston rod of the primary cylinder block 10, and the lower end of the piston rod 13 It is vertically fixed on the base 1; the upper end of the cylinder head 10-1 is provided with a channel stopper 7.

[0025] Two groups of reset tension springs are arranged between the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com