Low-temperature plasma multi-processing object experimental platform and processing method thereof

A low-temperature plasma and experimental platform technology, applied in the field of plasma processing platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

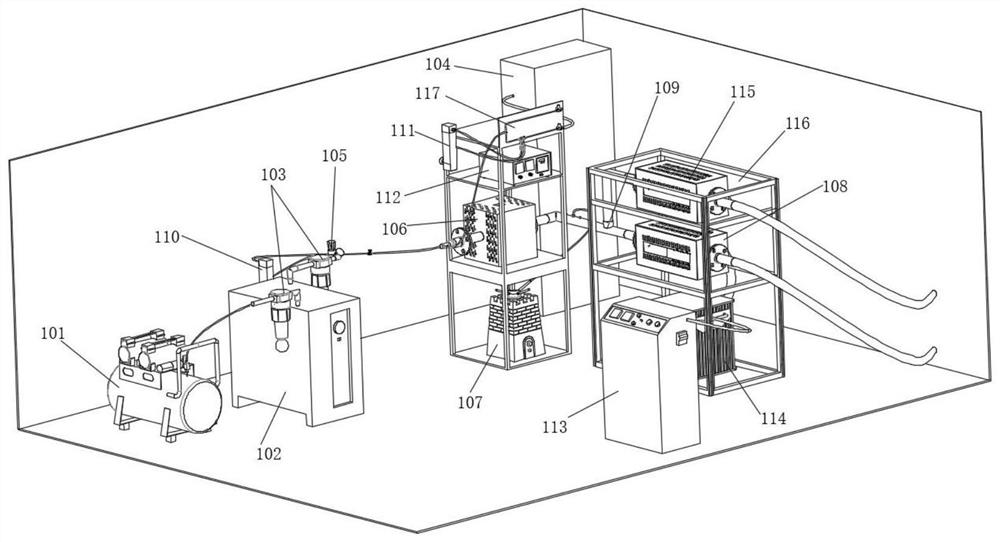

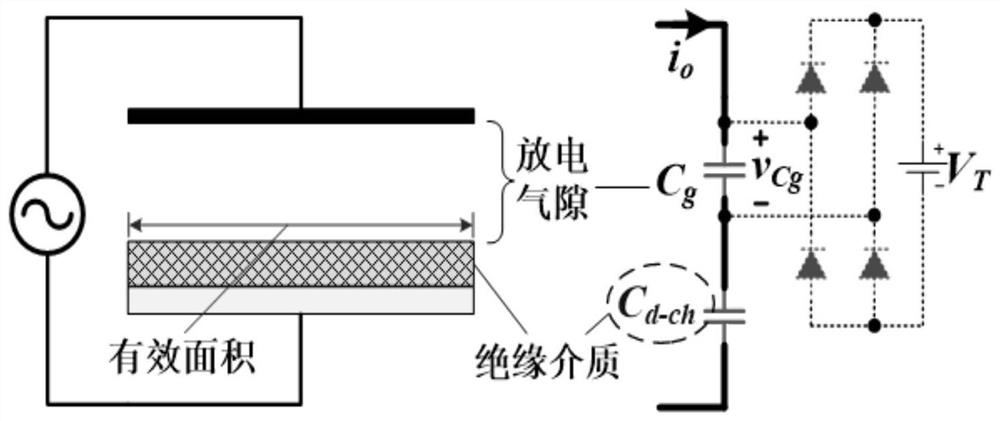

[0044] Embodiment 1: low temperature plasma multi-processing object experimental platform, such as figure 1 As shown, it includes an air compressor 101, a condensation dryer 102, a plurality of filters 103, an explosion-proof gas cylinder cabinet 104, a high-pressure pressure reducing valve 105, a tube furnace 106, a humidifier 107, a gas processing DBD reactor 108, a plate DBD The reactor 115, the high-voltage power supply 113 and the step-up transformer 114, the specification of the air compressor 101 is 750*2-50L, the voltage is 220V, the power is 1500W, 4 cylinders, the speed is 1400r / min, and the production volume is 120L / min. The working pressure is 0.5-0.8MPa; the model of the condensation dryer 102 is 7.5AC, the specification is HF-1, the inlet pressure is less than or equal to 1.02Mpa, the refrigerant type is R-12, the overall size is 700*400*595, and the gas processing capacity is 1.5m3 / min, the power of the matching air compressor 101 is 1.5KW-7.5KW; the model of t...

Embodiment 2

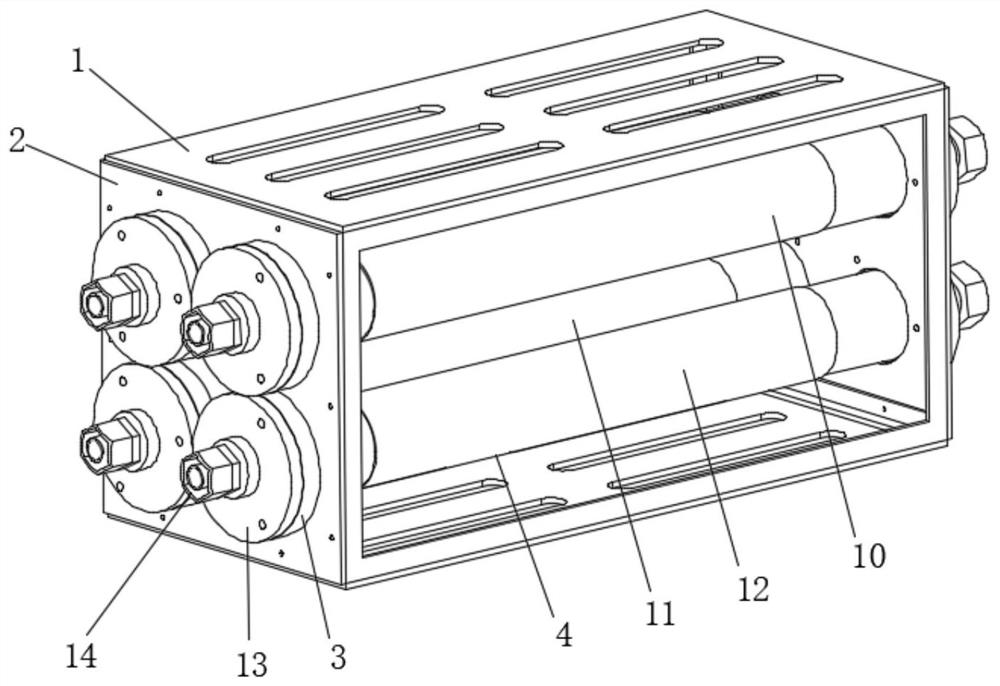

[0046] Embodiment 2: On the basis of embodiment 1, as Figure 3-4 As shown, it includes a frame body 1, the two ends of the frame body 1 are symmetrically provided with fixing plates 2, and a plurality of fixing covers 3 are arranged on the fixing plates 2; the frame body 1, the fixing plate 2 and the fixing cover 3 of the present invention are all Metal material, there is a DBD single tube 4 between the fixed covers 3 corresponding to both ends of the frame body 1, such as Figure 5As shown, the DBD single tube 4 includes a sleeve-shaped blocking medium layer 5 disposed between the fixed covers 3. The outer wall of the blocking medium layer 5 is sleeved with an external electrode 6, and the middle of the blocking medium layer 5 is provided with The inner electrode 7 whose end is fixed on the fixed cover 3, the gap between the inner electrode 7 and the barrier medium layer 5 forms a circulation pipe 8, and the gas in the circulation pipe 8 is purified under the negative ions g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com