Preparation method of scratch-resistant agent for polypropylene

A technology of scratch-resistant agent and polypropylene, which is applied in the field of polymers, can solve the problems of low toughness, large molding shrinkage, and poor creep resistance of polypropylene, and achieve low material loss rate, fewer process steps, and strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

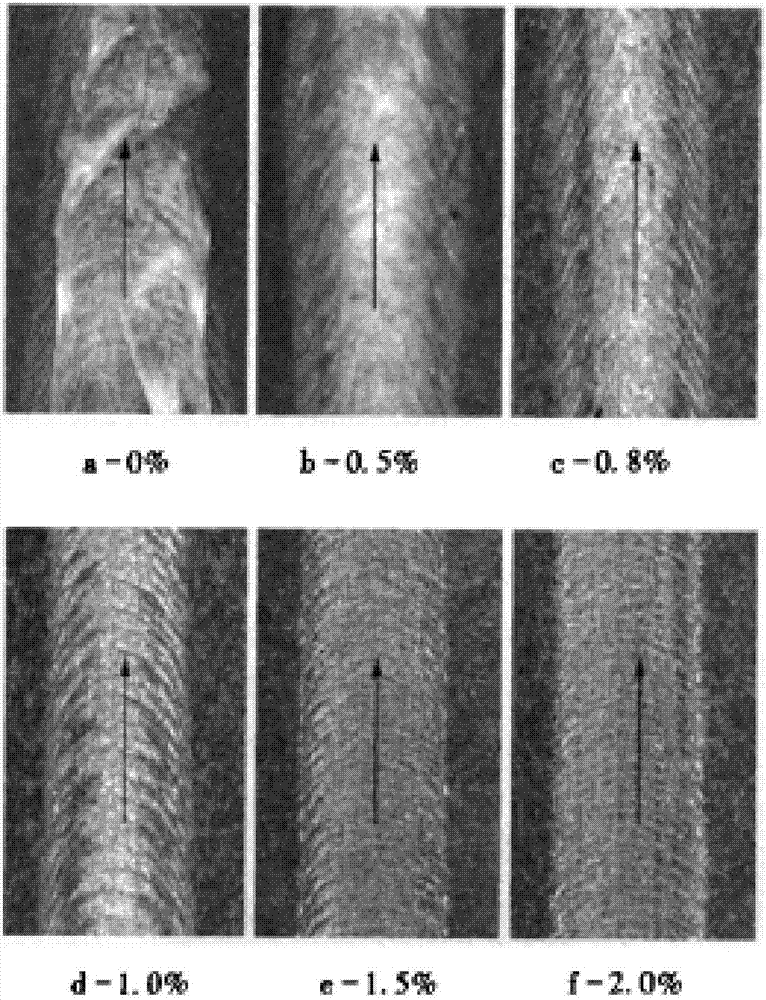

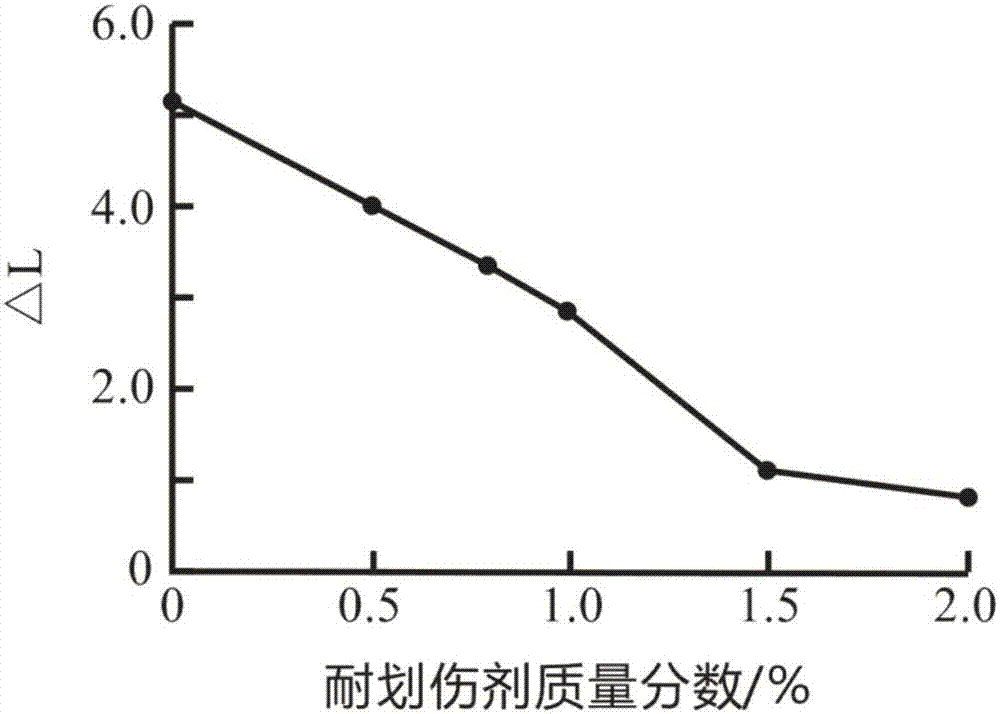

[0022] Weigh 60 parts of ethylene-ethyl acrylate copolymer, 20 parts of oleic acid amide, 10 parts of resorcinol type epoxy resin, 2 parts of light stabilizer (UV-770), 2,6-di-tert-butyl-4 - 2 parts of methyl phenol, mixed at high speed for 15 minutes with a high mixer, put the resulting material into the twin-screw extruder, and set 10 temperatures in the three areas of heating, constant temperature and heat preservation of the twin-screw extruder The temperature of the reference point is 60, 70, 90, 110, 130, 130, 130, 130, 130, and 130 degrees Celsius in turn, and the host speed of the twin-screw extruder is set to 450 rpm, the melt pressure is 1.9Mpa, and the outlet pressure 4MPa, extrusion granulation, cooling, pelletizing, to obtain pellets, collect the pellets and place them in an oven, set the drying temperature to 85 degrees Celsius, and last for 2 hours to obtain a polypropylene scratch-resistant Scratch agent, utilize ethylene-ethyl acrylate copolymer to have very g...

Embodiment 2

[0024] Weigh 62 parts of ethylene-ethyl acrylate copolymer, 22 parts of oleic acid amide, 12 parts of tetraphenol ethane type epoxy resin, 3 parts of light stabilizer (UV-770), 2,6-di-tert-butyl- 3 parts of 4-methylphenol, mixed at high speed for 20 minutes with a high mixer, put the resulting material into the twin-screw extruder, and set 10 heating, constant temperature, and heat preservation areas of the twin-screw extruder The temperature of the temperature reference point is 60, 70, 90, 110, 130, 130, 130, 130, 130, and 130 degrees Celsius in turn. Set the host speed of the twin-screw extruder to 500 rpm, the melt pressure to 2Mpa, and the outlet pressure 7MPa, extrusion granulation, cooling, pelletizing, to obtain pellets, collect the pellets and place them in an oven, set the drying temperature to 90 degrees Celsius, and last for 2 hours to obtain a polypropylene scratch-resistant Scratch agent, utilize ethylene-ethyl acrylate copolymer to have very good flexibility, he...

Embodiment 3

[0026] Weigh 65 parts of ethylene-ethyl acrylate copolymer, 25 parts of oleic acid amide, 13 parts of trishydroxyphenylmethane type epoxy resin, 5 parts of light stabilizer (UV-770), 2,6-di-tert-butyl- 5 parts of 4-methylphenol, mixed at high speed for 20 minutes with a high-mixer, put the obtained material into the twin-screw extruder, and set 10 heating, constant temperature, and heat preservation zones of the twin-screw extruder The temperature of the temperature reference point is 60, 70, 90, 110, 130, 130, 130, 130, 130, and 130 degrees Celsius in sequence. The pressure is 10 MPa, extrusion granulation, cooling, pelletizing, to obtain pellets, collect the pellets and place them in an oven, set the drying temperature to 95 degrees Celsius, and the duration is 2 hours to obtain a polypropylene resistant Scratch agent, utilize ethylene-ethyl acrylate copolymer to have good flexibility, thermal stability and processability characteristic, make the scratch resistance agent of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com