Aurum-ferric oxide/titanium dioxide nano-catalyst and preparation method thereof

A nano-catalyst, titanium dioxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc. The size and shape are easy to control, and the effect of reducing the variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

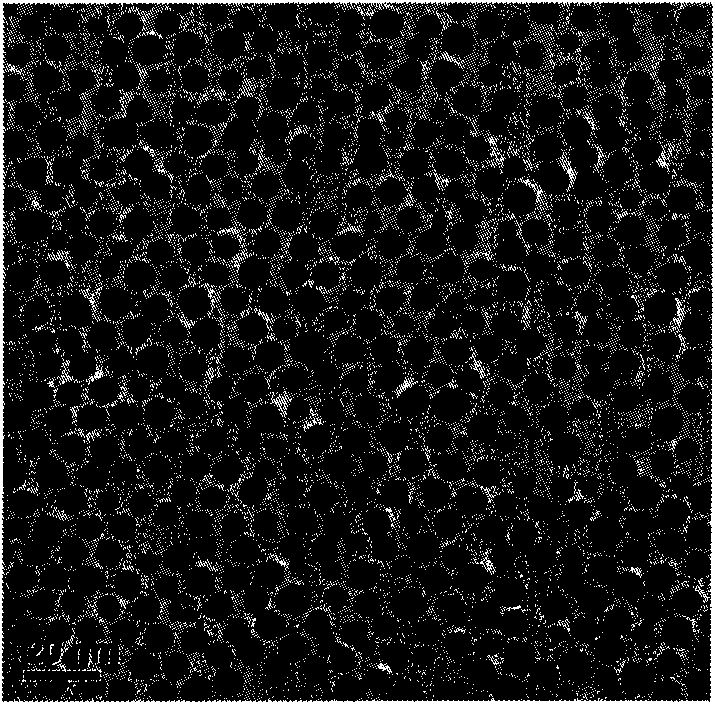

[0026] Embodiment 1: Preparation of 2% Au-Fe 3 o 4 (spherical) / TiO 2 nanocatalyst

[0027] Take 1.00g HAuCl 4 In a 250ml double-necked flask, quickly add 100ml CHCl 3 , then add 20ml oleylamine, shake and sonicate until the solution is a clear orange-red transparent solution. Under nitrogen protection, 0.50 g of tert-butylamine borane was added dropwise to the orange-red transparent solution under the condition of magnetic stirring at 30° C., and stirred for 15 min. After the reaction, add 400ml ethanol, centrifuge at 8000rpm for 5min, and disperse in 100ml CHCl 3 middle. (Such as figure 1 ) then get 70.0mg iron acetylacetonate and add 4ml oleylamine and 2.67ml oleic acid in a 25ml three-necked flask, vacuumize, fill with nitrogen repeatedly 3 times, get the CHCl of Au prepared above 3 Add 5ml of ethanol to 1ml of the solution (5mgAu), centrifuge at 4000rpm, and disperse the obtained precipitate in 2ml of oleylamine. Heat the solution in the three-necked flask to 180°...

Embodiment 2

[0028] Embodiment 2: Preparation of 5% Au-Fe 3 o 4 (square) / TiO 2 Nano catalyst:

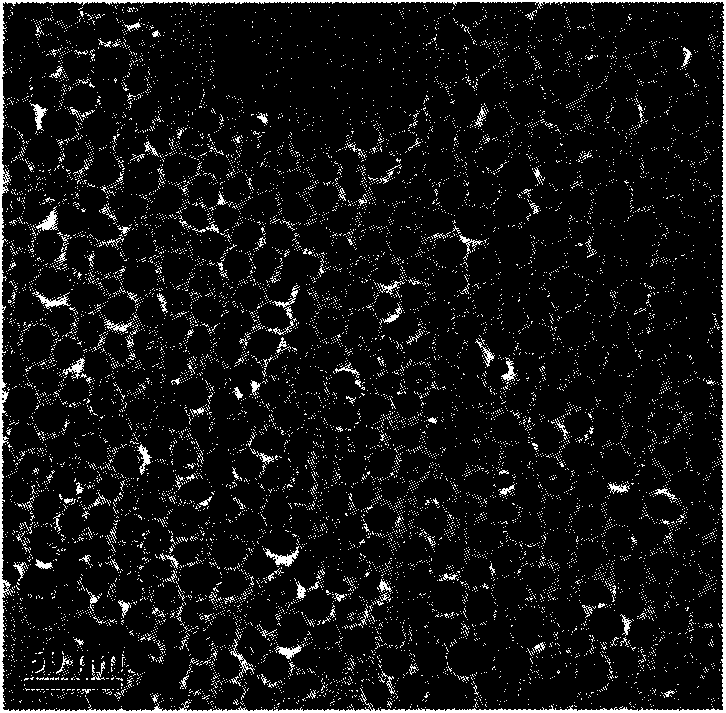

[0029] Take 0.5g HAuCl 4 In a 250ml double-necked flask, quickly add 100ml CHCl 3 , then add 10ml oleylamine, shake and sonicate until the solution is a clear orange-red transparent solution, add 0.25g tert-butylamine borane dropwise to the above-mentioned orange-red transparent solution under the condition of nitrogen protection and magnetic stirring at 25°C Go, stir for 15min. After the reaction, add 200ml ethanol, centrifuge at 8000rpm for 5min, and disperse in 50ml CHCl 3 middle. Take 1 mL of the above Au in CHCl 3 Solution (5mgAu) into a microwave tube with a volume of 10mL, add 8mL of absolute ethanol, centrifuge at 6000rpm for 2min, pour off the supernatant, invert until most of the ethanol flows out, then add 1mL of oleic acid, add a magnet, cover the lid, 50 Stir in a water bath at ℃ until Au is completely dispersed, then add 40 mg of iron acetylacetonate, 40 mg of 1,2-hexadecan...

Embodiment 3

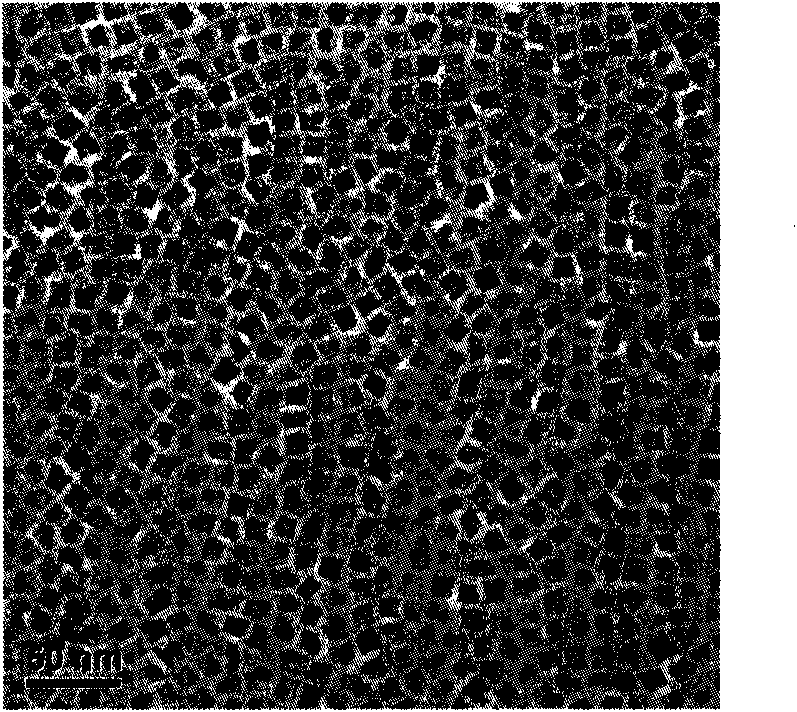

[0030] Embodiment 3: Preparation of 2.5% Au-Fe 3 o 4 (flower shape) / TiO 2 nanocatalyst

[0031] Take 1.5g HAuCl 4 In a 250ml double-necked flask, quickly add 150ml CHCl 3 , then add 30ml oleylamine, shake and sonicate until the solution is a clear orange-red transparent solution, add 0.75g tert-butylamine borane dropwise to the above-mentioned orange-red transparent solution under the condition of nitrogen protection and magnetic stirring at 35°C Go, stir for 15min. After the reaction, add 200ml ethanol, centrifuge at 8000rpm for 5min, and disperse in 150ml CHCl 3 middle. Take 1 mL of the above Au in CHCl 3 (5mgAu) into a microwave tube with a volume of 10mL, add 8mL of absolute ethanol, centrifuge at 6000rpm for 2min, pour off the supernatant, invert until most of the ethanol flows out, then add 1mL of oleic acid, add a magnet, cover the lid, 50 Stir in a water bath at ℃ until Au is completely dispersed, then add 50mg of iron acetylacetonate, 50mg of 1,2-hexadecanedio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com