BOPE film and preparation method thereof

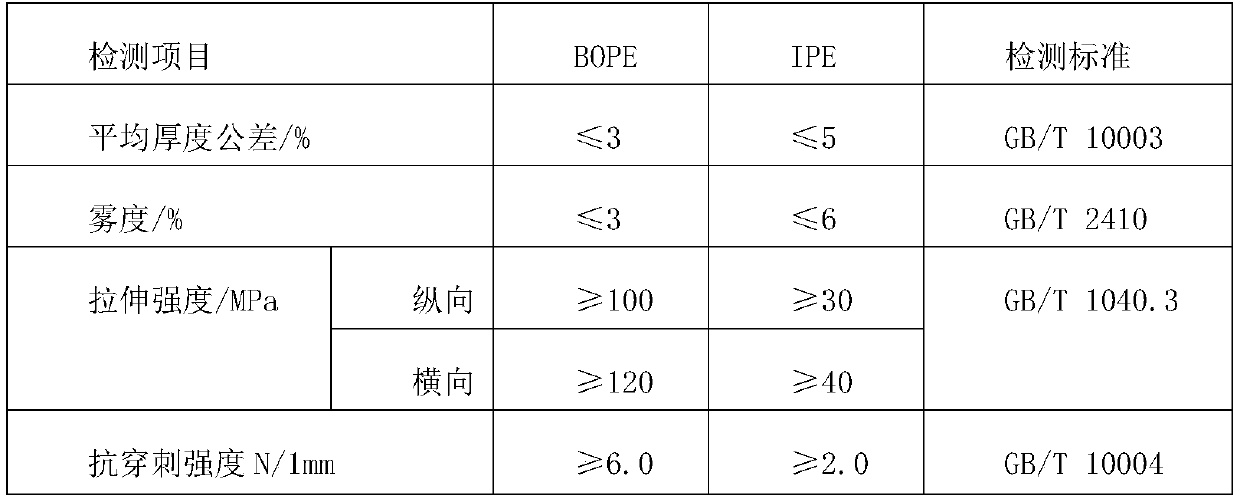

A film and surface layer technology, which is applied in the field of polyolefin film, can solve the problems of lack of competitiveness in the packaging field and insufficient physical properties of IPE film, and achieve excellent impact resistance and puncture resistance, small deformation, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A BOPE film is a three-layer structure consisting of a core layer, an upper surface layer and a lower surface layer; the core layer is 1%wt antistatic masterbatch and 99%wt M-LLDPE; the upper surface layer is 2%wt antistatic masterbatch and 98%wt M-LLDPE; the lower surface layer is 3%wt anti-blocking masterbatch and 97%wt M-LLDPE; the antistatic masterbatch is the compound of ethoxylated amine, glycerol monostearate and M-LLDPE The above-mentioned anti-adhesive masterbatch is a compound of oleic acid amide and M-LLDPE.

[0022] The preparation method is as follows:

[0023] a. The raw materials of the core layer are sent to the main extruder to be heated and melted after proportioning and drying, the raw materials of the upper surface layer are heated and melted in an auxiliary extruder after proportioning, and the raw materials of the lower surface layer are heated and melted in an auxiliary extruder after proportioning. It is heated and melted in the machine; the obt...

Embodiment 2

[0030] A BOPE film is a three-layer structure consisting of a core layer, an upper surface layer and a lower surface layer; the core layer is 3%wt antistatic masterbatch and 97%wt M-LLDPE; the upper surface layer is 4%wt antistatic masterbatch and 96%wt M-LLDPE; the lower surface layer is 5%wt anti-blocking masterbatch and 95%wt M-LLDPE; The above-mentioned anti-adhesive masterbatch is a compound of oleic acid amide and M-LLDPE.

[0031] The preparation method is as follows:

[0032] a. The raw materials of the core layer are sent to the main extruder to be heated and melted after proportioning and drying, the raw materials of the upper surface layer are heated and melted in an auxiliary extruder after proportioning, and the raw materials of the lower surface layer are heated and melted in an auxiliary extruder after proportioning. It is heated and melted in the machine; the obtained three-layer melt is filtered through a 400-mesh filter screen, and then combined and extruded...

Embodiment 3

[0039] A BOPE film is a three-layer structure consisting of a core layer, an upper surface layer and a lower surface layer; the core layer is 2%wt antistatic masterbatch and 98%wt M-LLDPE; the upper surface layer is 3%wt antistatic masterbatch and 97%wt M-LLDPE; the lower surface layer is 4%wt anti-blocking masterbatch and 96%wt M-LLDPE; The above-mentioned anti-adhesive masterbatch is a compound of oleic acid amide and M-LLDPE.

[0040] The preparation method is as follows:

[0041] a. The core material is sent to the main extruder to be heated and melted after proportioning and drying, the upper surface material is heated and melted in an auxiliary extruder after proportioning, and the lower surface material is mixed in an auxiliary extruder after proportioning. It is heated and melted in the machine; the obtained three-layer melt is filtered through a 400-mesh filter screen, and then combined and extruded in a three-layer structure die. The die temperature was 232°C.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com