Special powder metallurgy lubricant for stainless steel and preparation method thereof

A powder metallurgy and stainless steel technology, applied in the field of special powder metallurgy lubricant for stainless steel and its preparation, can solve the problems of unsatisfactory improvement of flow rate and pressing performance, relatively large influence on product green strength, unstable filling of mixed powder, etc. The effect of low demoulding force, less residual ash and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

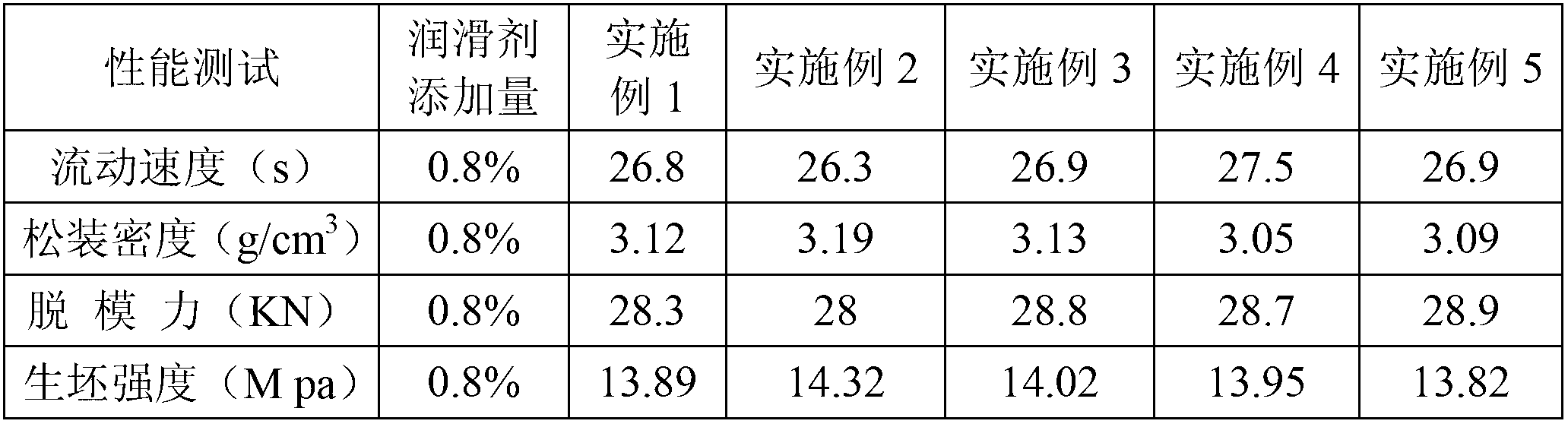

Examples

Embodiment 1

[0025] A preparation method of a special powder metallurgy lubricant for stainless steel. The specific operation steps are: mixing the raw material stearate, oleic acid amide and vinyl bisstearamide at normal temperature 20°C-25°C, heating to temperature T 1 150℃~170℃, after heating at constant temperature for 20min~40min, after the raw materials are mixed evenly, cool the homogeneously mixed raw material mixture to the temperature T 2 Grinding, crushing and sieving at a temperature of 20°C to 30°C to obtain finished powder metallurgy lubricants for stainless steel.

[0026] The mass percentage of stearate is 10%-40%, the weight percentage of oleic acid amide is 10%-40%, and the weight percentage of the vinylbisstearamide is 40%-70%.

[0027] Commonly used stearate lubricants are zinc stearate, magnesium stearate, barium stearate, sodium stearate, calcium stearate, aluminum stearate, 12-hydroxy lithium stearate and stearic acid Lithium, due to the residual zinc oxide in the p...

Embodiment 2

[0033] Same as Example 1, the difference is:

[0034] The weight percentage of lithium stearate is 20%, the weight percentage of oleic acid amide is 20%, and the weight percentage of vinylbisstearamide is 60%.

Embodiment 3

[0036] Same as Example 1, the difference is:

[0037] The weight percentage of lithium stearate is 40%, the weight percentage of oleic acid amide is 10%, and the weight percentage of vinylbisstearamide is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com