Antibacterial and odor-resistant spun-bonded non-woven fabric, planar mask with spun-bonded non-woven fabric and manufacturing method of planar mask

A technology of spun-bonded non-woven fabrics and melt-blown non-woven fabrics, which is applied in the manufacture of protective clothing, non-woven fabrics, and rayon, and can solve the problems of poor filtering effect of flat masks, discomfort when worn, sweat absorption, and moisture drainage Poor air permeability and other problems, to save manpower and equipment costs, good antibacterial and deodorizing effects, and excellent performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A kind of antibacterial deodorant spun-bonded non-woven fabric is made of the following raw materials by weight:

[0064] 75-85 parts of polypropylene,

[0065] 15-19 parts of metallocene-catalyzed linear low-density polyethylene,

[0066] 2-2.5 parts of mesoporous silica,

[0067] 3-4 parts of sepiolite powder,

[0068] 1.2-1.4 parts of dichlorophenyl imidazole dioxolane,

[0069] 2.2 to 2.6 copies of Avermycin,

[0070] 1-1.6 parts of maleic anhydride grafted polypropylene,

[0071] 1 to 1.5 parts of oleic acid amide,

[0072] 1.5-2 parts of erucamide,

[0073] Heat stabilizer 1~1.5 parts,

[0074] 3-5 parts of polypropylene cooling masterbatch.

[0075] In this embodiment, the antibacterial and deodorant spunbond non-woven fabric is preferably, but not limited to, made of raw materials including the following parts by weight:

[0076] 80 parts of polypropylene,

[0077] Metallocene catalyzed linear low density polyethylene 17 parts,

[0078] Mesoporous sil...

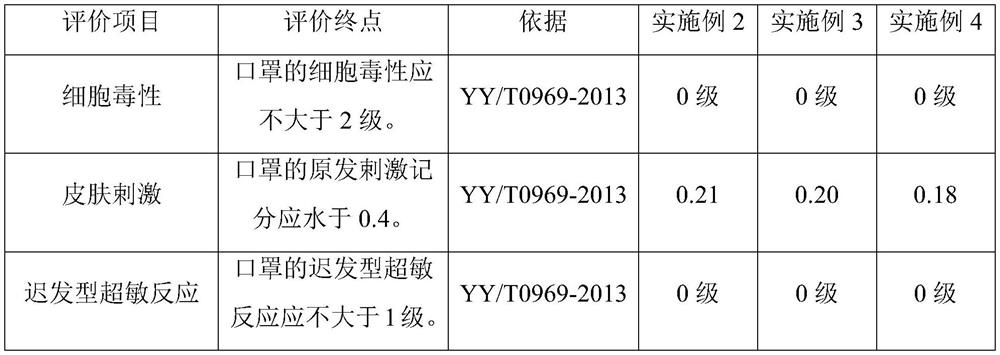

Embodiment 2

[0132] A kind of antibacterial deodorant spun-bonded non-woven fabric is made of the following raw materials by weight:

[0133] 75 parts of polypropylene,

[0134] Metallocene catalyzed linear low density polyethylene 15 parts,

[0135] Mesoporous silica 2 parts,

[0136] 3 parts meerschaum powder,

[0137] 1.2 parts of dichlorophenyl imidazole dioxolane,

[0138] Avermycin 2.2 parts,

[0139] Maleic anhydride grafted polypropylene 1 part,

[0140] 1 part of oleic acid amide,

[0141] 1.5 parts of erucamide,

[0142] 1 part heat stabilizer,

[0143] 3 parts of polypropylene cooling masterbatch.

[0144] In this embodiment, the avermycin is a mixture of avermycin A and avermycin B.

[0145] In the present embodiment, the mass ratio of avermycin A and avermycin B in the mixture of avermycin A and avermycin B is 1:0.62.

[0146] In this embodiment, the polypropylene is a mixture of syndiotactic polypropylene and atactic polypropylene.

[0147] In this embodiment, the ...

Embodiment 3

[0159] A kind of antibacterial deodorant spun-bonded non-woven fabric is made of the following raw materials by weight:

[0160] 85 parts of polypropylene,

[0161] Metallocene catalyzed linear low density polyethylene 19 parts,

[0162] Mesoporous silica 2.5 parts,

[0163] 4 parts meerschaum powder,

[0164] 1.4 parts of dichlorophenyl imidazole dioxolane,

[0165] Avermycin 2.6 parts,

[0166] 1.6 parts of maleic anhydride grafted polypropylene,

[0167] 1.5 parts of oleic acid amide,

[0168] Erucamide 2 parts,

[0169] Heat stabilizer 1.5 parts,

[0170] 5 parts of polypropylene cooling masterbatch.

[0171] In this embodiment, the avermycin is a mixture of avermycin A and avermycin B.

[0172] In the present embodiment, the mass ratio of avermycin A and avermycin B in the mixture of avermycin A and avermycin B is 1:0.68.

[0173] In this embodiment, the polypropylene is a mixture of syndiotactic polypropylene and atactic polypropylene.

[0174] In this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com