Antibacterial breathable plastic masterbatch and preparation method and application thereof

A plastic masterbatch and anti-oxidant technology, applied in the field of plastic materials, can solve the problems of ductility and tensile strength weakening, increase the content of inorganic fillers, unfavorable environmental protection and cost control, etc., to reduce retention and improve fluidity , good purity and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

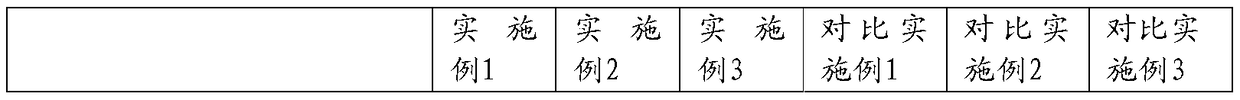

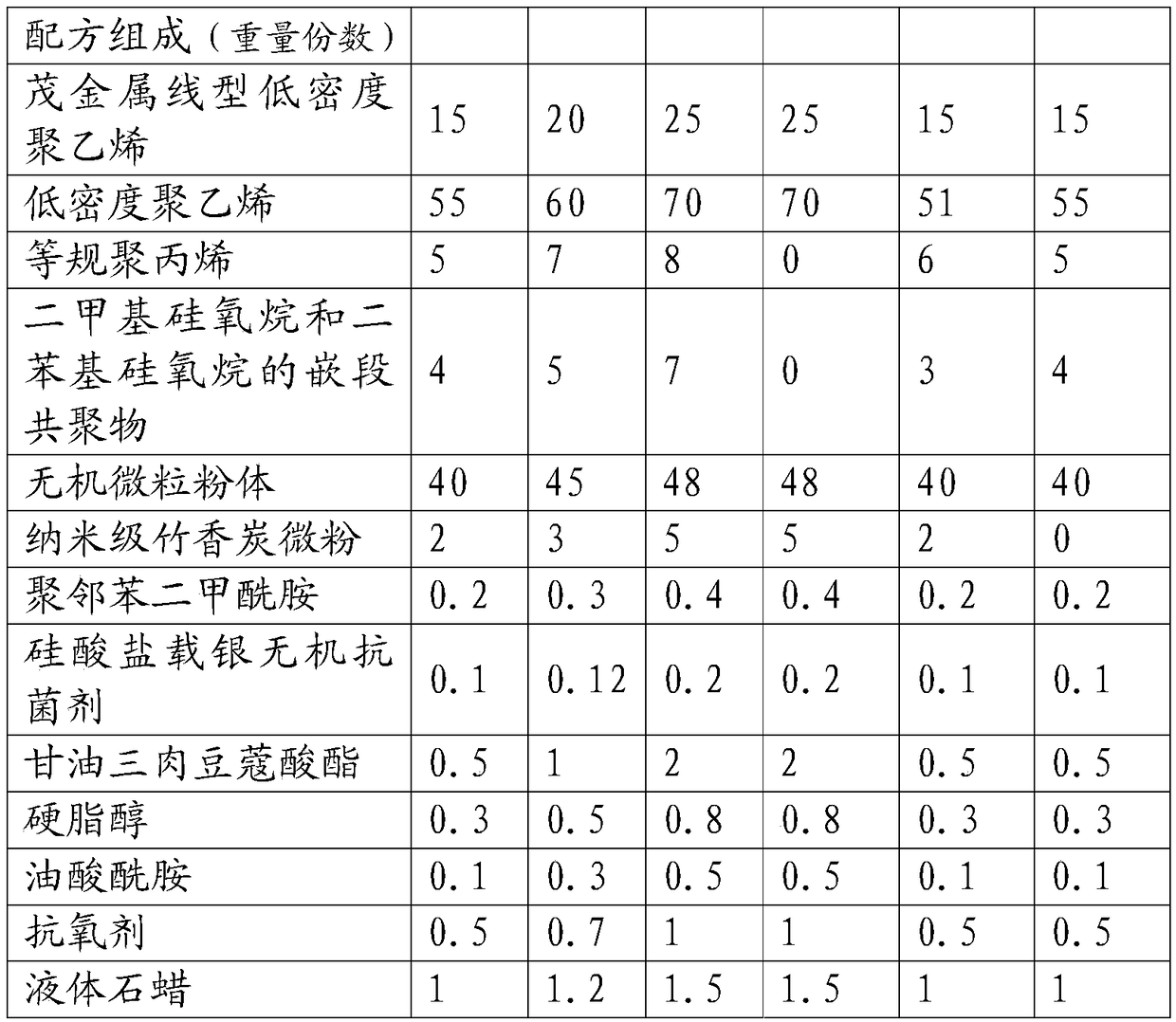

[0025] The present invention will be further described below in conjunction with specific examples.

[0026] Formulation composition as shown in table 1 weighs the component of parts by weight, and makes the antibacterial breathable plastic masterbatch of the present invention as follows: In the mixer, add monoglyceride stearate, stir at room temperature for 20 minutes, and modify the interface to become raw material 1;

[0027] (2) Weigh parts by weight of metallocene linear low density polyethylene, low density polyethylene and isotactic polypropylene and place them in a mixer and stir evenly, then send them into a high-speed kneader, and then add dimethyl siloxane and Block copolymer of diphenylsiloxane, glyceryl trimyristate, stearyl alcohol, raw material 1, polyphthalamide, oleic acid amide, antioxidant, liquid paraffin, the interval between two feedings Not less than 3 minutes, the temperature of the kneader does not exceed 90°C, and the kneader is stirred at 100r / min f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com