Antifouling coating for marine net wire and preparation method of antifouling coating

A technology of anti-fouling coating and network cable, which is applied in the field of material science, can solve the problems of flexibility and low bactericidal activity, and achieve the effects of improving hydrophilicity, improving bactericidal activity, good adhesion and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

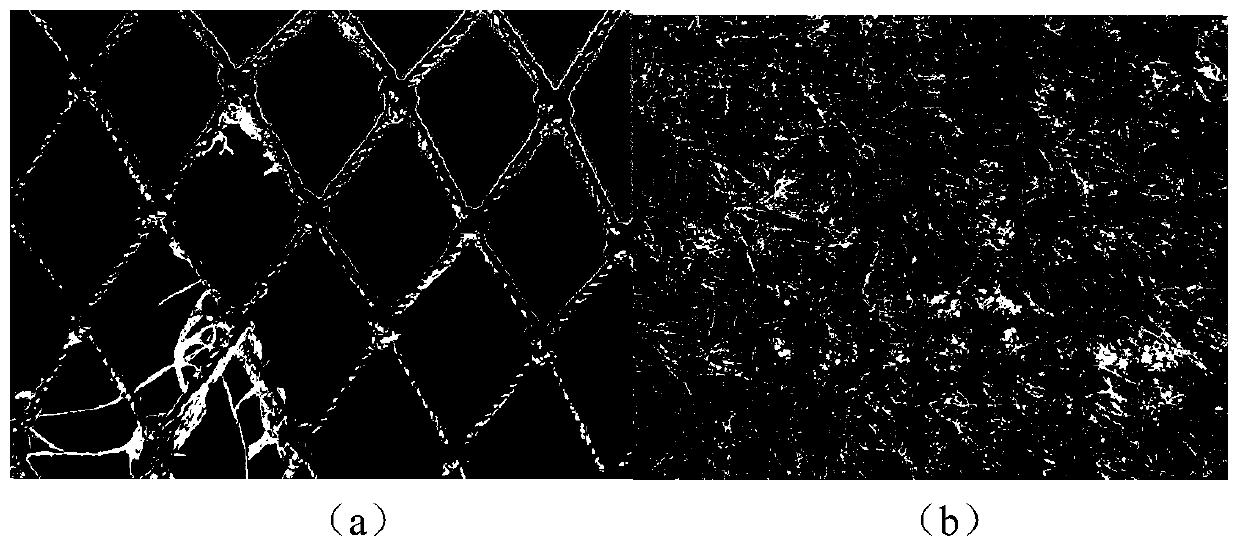

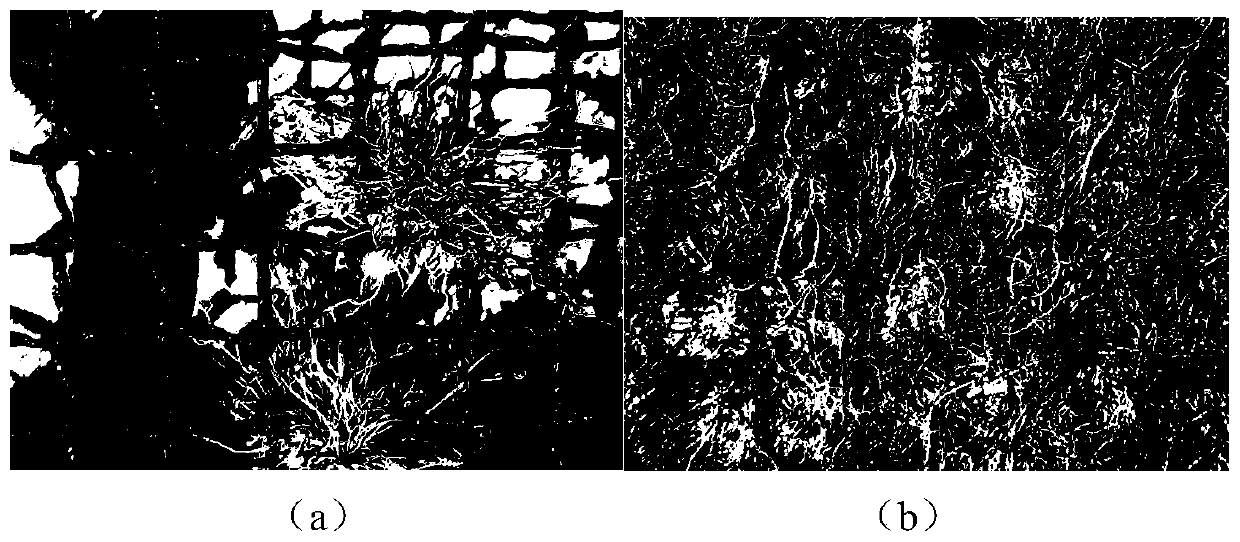

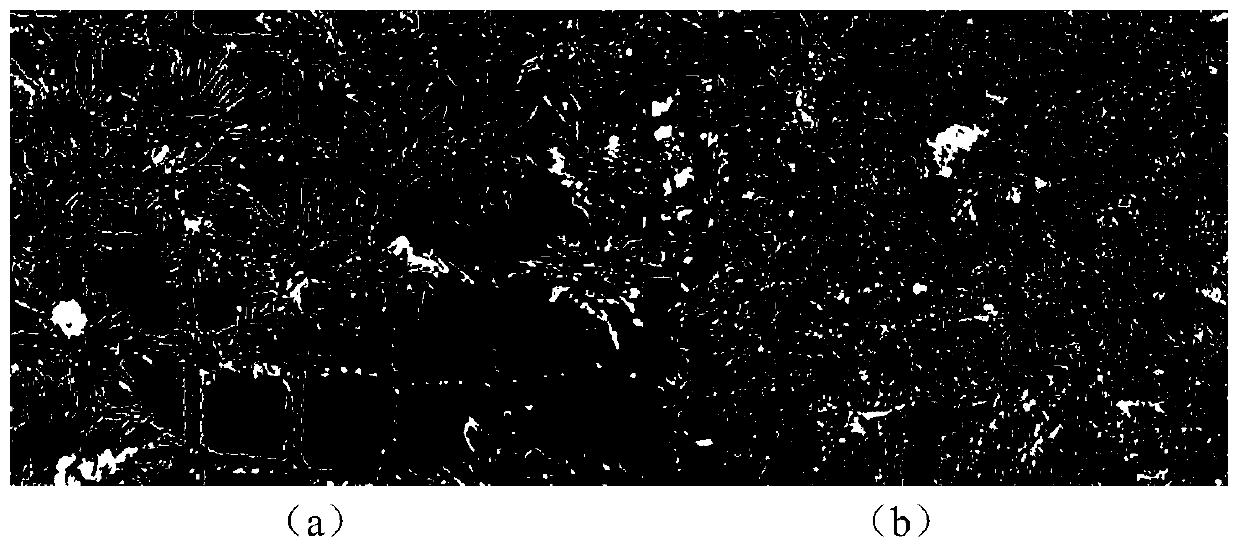

Image

Examples

Embodiment 1

[0040] A method for preparing an antifouling coating for marine network cables, comprising the following steps:

[0041] (1) Modified nano-zinc oxide: a. Mix nano-zinc oxide and coupling agent in a xylene solution with a mass ratio of 15:0.8, heat and stir, the heating temperature is 75°C, the heating time is 3h, and the stirring speed is 400 rpm, the coupling agent is vinyltriethoxysilane; b, drop to room temperature and filter, add diethyl ether to precipitate the filtrate, and then dry to obtain modified nano-zinc oxide with a particle size of 35nm.

[0042] (2) Preparation of multi-component acrylic acid composite resin: 0.5g of azobisisobutyronitrile, 50g of xylene, 12g of styrene, 20g of n-pentyl acrylate, 18g of isobornyl methacrylate and 15g of diisobutylene were mixed in a four-necked flask , stirred for 25 minutes, and the stirring speed was 550 rpm to obtain a multi-component acrylic composite resin. The number-average molecular weight of the obtained multi-componen...

Embodiment 2

[0047] The difference with Example 1 is that a preparation method of marine network cable antifouling coating comprises the following steps:

[0048] (1) Modified nano-zinc oxide: a. Mix nano-zinc oxide and coupling agent in xylene solution at a mass ratio of 10:0.5, heat and stir, the heating temperature is 60°C, the heating time is 2.5h, and the stirring speed 150 rev / min, the coupling agent is vinyltriethoxysilane; b. Cool down to room temperature and filter, add diethyl ether to precipitate the filtrate, and then dry to obtain modified nano-zinc oxide with a particle size of 20nm.

[0049] (2) Preparation of multi-component acrylic acid composite resin: 0.2g azobisisobutyronitrile, 45g xylene, 9g styrene, 16g amyl acrylate, 9g isobornyl methacrylate and 10g diisobutylene were mixed in a four-necked flask, Stir for 20 minutes at a stirring speed of 300 rpm to obtain a multi-component acrylic composite resin. The number-average molecular weight of the obtained multi-componen...

Embodiment 3

[0054] The difference with Example 1 is that a preparation method of an antifouling coating for marine network cables comprises the following steps: (1) modifying nano-zinc oxide: a, using nano-zinc oxide and coupling agent in a mass ratio of 20:1 Mix in xylene solution, heat and stir, the heating temperature is 90°C, the heating time is 3.5h, the stirring speed is 600 rpm, and the coupling agent is vinyltriethoxysilane; b, drop to room temperature and filter , add diethyl ether to precipitate the filtrate, and then dry to obtain the modified nano zinc oxide with a particle size of 50nm.

[0055] (2) Preparation of multi-component acrylic acid composite resin: 0.8g azobisisobutyronitrile, 55g xylene, 15g styrene, 25g amyl acrylate, 25g isobornyl methacrylate and 20g diisobutylene were mixed in a four-necked flask, Stir for 30 minutes at a stirring speed of 800 rpm to obtain a multi-component acrylic composite resin with a number-average molecular weight of 6750, a weight-avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com