Degradable chitosan-based composite hemostatic film

A chitosan and film technology, applied in coating, medical science, absorbent pads, etc., can solve the problems of easy aggregation of powder, hemostatic effect, secondary injury material comfort, leakage, etc., achieve excellent anti-infection function, promote The effect of wound healing and avoidance of vascular embolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

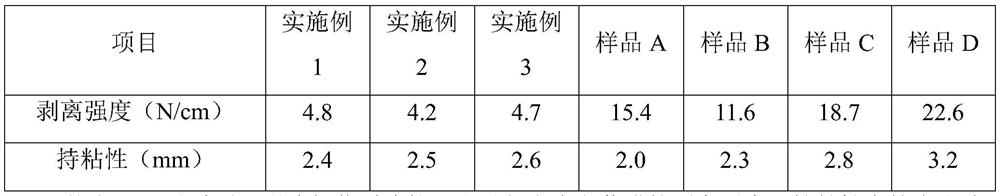

Embodiment 1

[0031] A degradable chitosan-based composite hemostatic film, comprising a substrate layer and a functional layer; the substrate layer is polycarbonate fiber cloth; the functional layer is modified chitosan, polyethylene glycol 2000, gelatin, Xanthan gum, Ag / Fe 2 o 3 The composite hydrogel prepared by magnetic nanoparticles, wrought stamen, and oleic acid amide, the functional layer is combined with the substrate layer through polydopamine; the ratio of parts by weight of the raw materials for the preparation of the functional layer is: modified chitosan 150 parts, polyethylene glycol 2000 10 parts, gelatin 40 parts, xanthan gum 20 parts, Ag / Fe 2 o 3 14 parts of magnetic nanoparticles, 25 parts of wrought stamen, and 0.2 parts of oleic acid amide.

[0032] The preparation method of the modified chitosan is: dissolving the chitosan powder in 1wt% acetic acid to form a 1wt% chitosan-acetic acid solution, adding hexanal, stirring at room temperature for 12 hours, adjusting the...

Embodiment 2

[0040] A degradable chitosan-based composite hemostatic film, comprising a substrate layer and a functional layer; the substrate layer is polylactic acid fiber cloth; the functional layer is modified chitosan, polyethylene glycol 2000, gelatin, Xanthan gum, Ag / Fe 2 o 3 The composite hydrogel prepared by magnetic nanoparticles, wrought stamen, and oleic acid amide, the functional layer is combined with the substrate layer through polydopamine; the ratio of parts by weight of the raw materials for the preparation of the functional layer is: modified chitosan 120 parts, polyethylene glycol 2000 8 parts, gelatin 32 parts, xanthan gum 16 parts, Ag / Fe 2 o 3 10 parts of magnetic nanoparticles, 18 parts of wrought stamen, and 0.15 parts of oleic acid amide.

[0041] The preparation method of the modified chitosan is: dissolving the chitosan powder in 1wt% acetic acid to form a 1wt% chitosan-acetic acid solution, adding dodecanal, stirring at room temperature for 12 hours, adjusting...

Embodiment 3

[0049] A degradable chitosan-based composite hemostatic film, comprising a substrate layer and a functional layer; the substrate layer is polycaprolactone fiber cloth; the functional layer is modified chitosan, polyethylene glycol 2000, Gelatin, Xanthan Gum, Ag / Fe 2 o 3 The composite hydrogel prepared by magnetic nanoparticles, wrought stamen, and oleic acid amide, the functional layer is combined with the substrate layer through polydopamine; the ratio of parts by weight of the raw materials for the preparation of the functional layer is: modified chitosan 90 parts, polyethylene glycol 2000 6 parts, gelatin 24 parts, xanthan gum 12 parts, Ag / Fe 2 o 3 6 parts of magnetic nanoparticles, 12 parts of wrought stamen, and 0.1 part of oleic acid amide.

[0050] The preparation method of the modified chitosan is as follows: dissolving the chitosan powder in 1wt% acetic acid to form a 1wt% chitosan-acetic acid solution, adding octadecanal, stirring at room temperature for 12 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com