Patents

Literature

46results about How to "High synthetic conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of low-free TDI polyurethane curing agent, curing agent therefrom and its products

A low-free radical TDI polyurethane curing agent, its production and product are disclosed. The process is carried out by putting tolylene-diisoester cyanate, solvent S and catalyst A into reactor, adding into antioxidant and long-chain alcohol, agitating in reactor, heating, keeping temperature, inspecting NCO value, adding into phase-transferring solvent X while reaching NCO value to 20-40%, adding into catalyst B till reaching NCO value to 10-15, adding into inhibitor to stop reaction, adding into solvent S, decreasing pressure, distilling and removing phase-transferring solvent X. It's cheap and convenient.

Owner:BEIJING ZHANCHEN CHEM +2

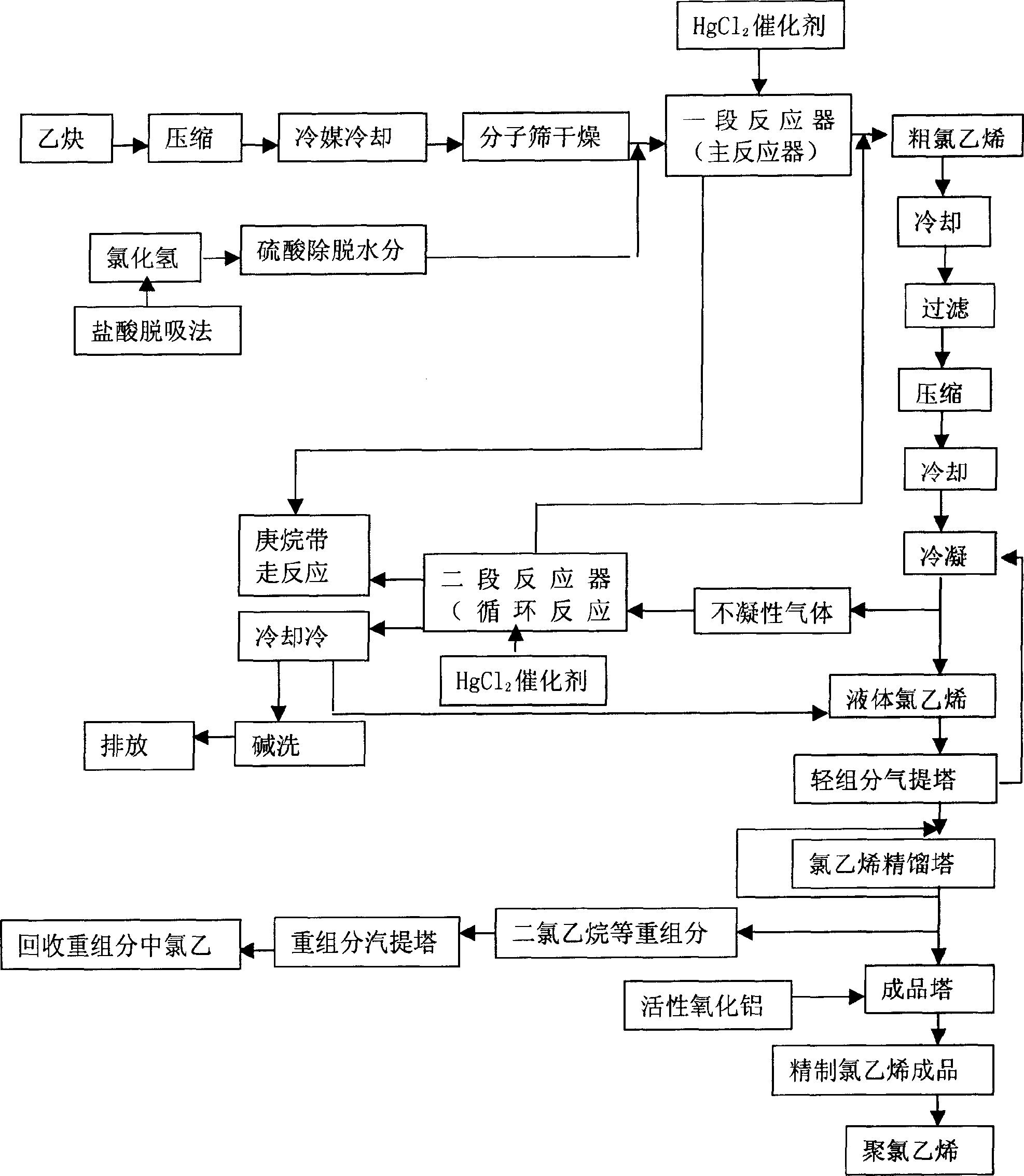

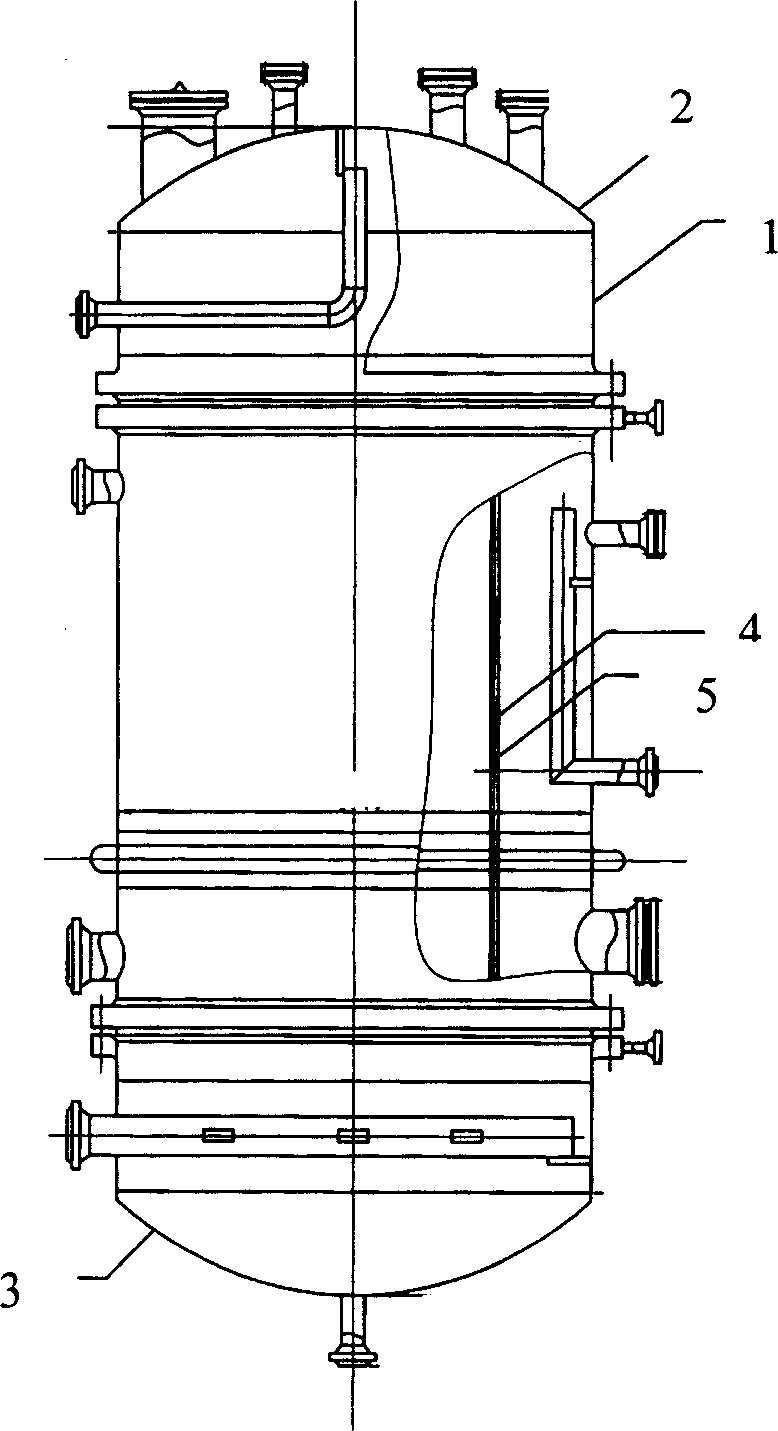

Process for producing vinyl chloride by acetylene method and dedicated device for realizing same

InactiveCN1884241ASmooth responseAvoid corrosionPreparation by halogen halide additionSewage treatmentUltimate tensile strength

The invention discloses a new method of chloroethylene through acetylene method and specific equipment, which comprises the following steps: disposing raw material gas strictly; reacting two-segment compensation; recycling heptane; cooling; radiating; providing specific catalyst and reactor to synthesize chloroethylene; disposing effluent with mercury to obtain high-purity chloroethylene monomer.

Owner:刘大军

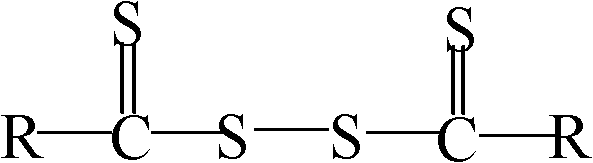

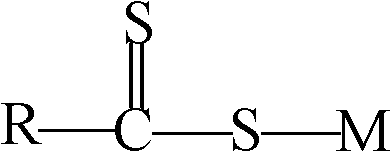

Insoluble sulfur stabilizing agent and preparation method thereof

The invention discloses an insoluble sulfur stabilizing agent and a preparation method thereof. The insoluble sulfur stabilizing agent has a chemical structural formula as shown in the specification, and the molecular weight is 218-465, wherein R is C2-C20 linear-chain or branched-chain alkoxy or amino; and the stabilizing agent is generated through reaction by using an organic acid salt and an oxidant as raw materials and using water, acetone or fatty alcohol as a reaction medium. The stabilizing agent can be applied to an insoluble sulfur production process, can be uniformly dispersed in insoluble sulfur, can greatly improve the high-temperature stability of insoluble sulfur, and has the characteristics of mild process conditions, available raw materials, low synthesis cost, high product yield and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

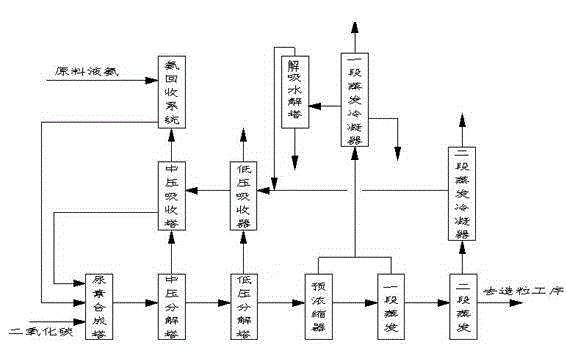

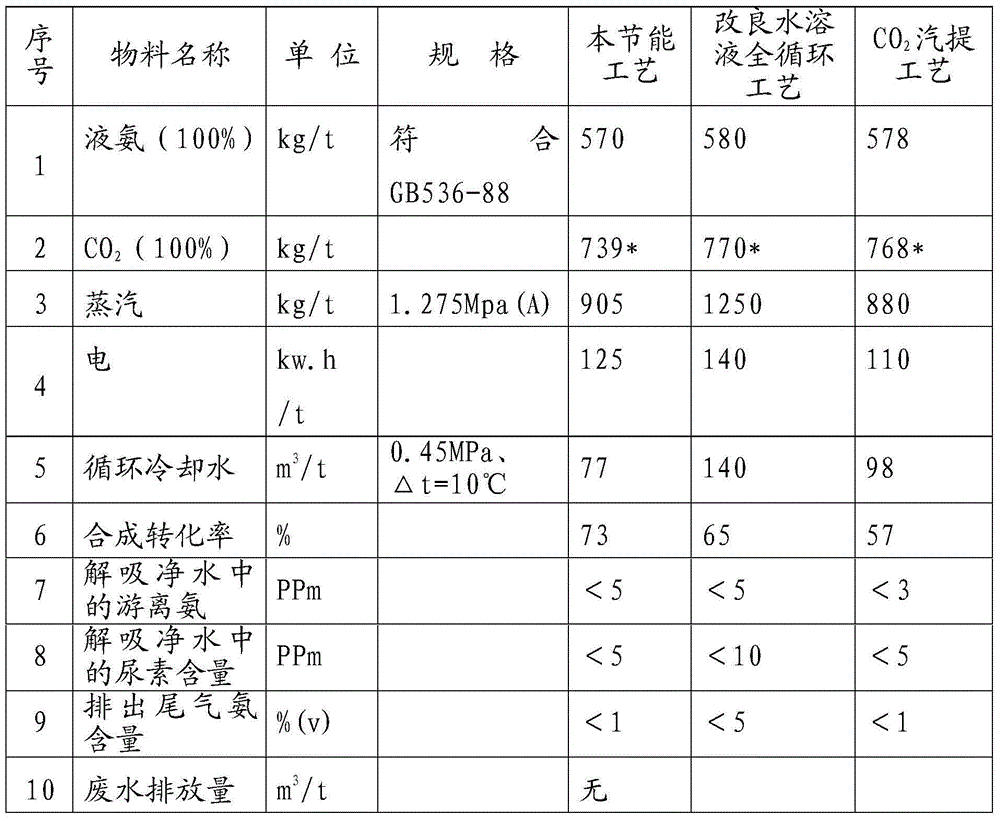

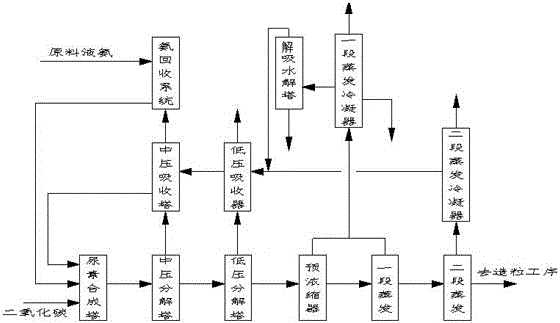

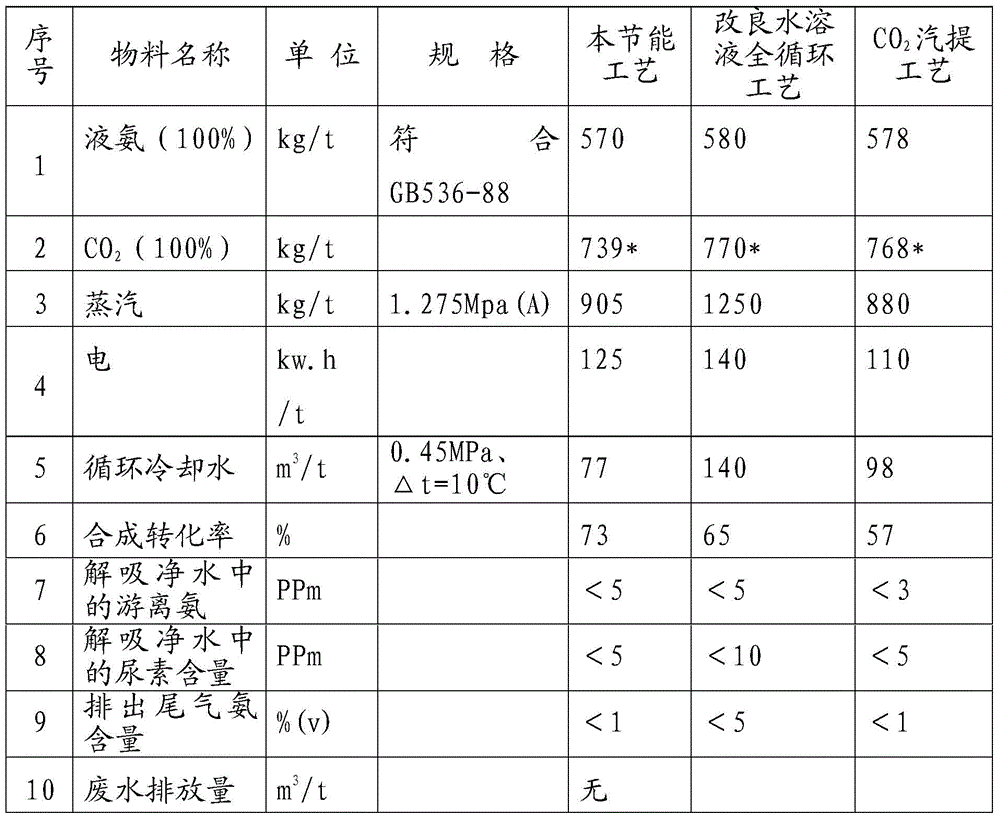

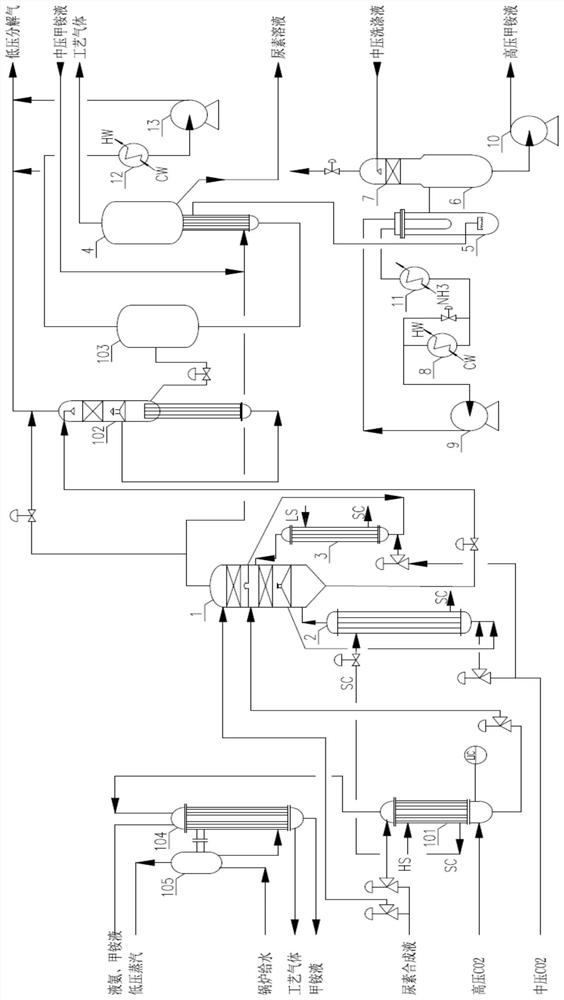

Energy-saving urea production system and production process thereof

ActiveCN104829494AReduce energy consumptionEasy to operateUrea derivatives preparationOrganic compound preparationDesorptionAmmonium carbamate

The invention belongs to the field of urea preparation, and particularly relates to an energy-saving urea production system and a production process thereof. The system comprises a CO2 compressor, an ammonium carbamate pump, a liquid ammonia pump and a urea synthesizer. The system is characterized in that the CO2 compressor is connected with the ammonium carbamate pump and the liquid ammonia pump, the liquid ammonia pump is connected with the urea synthesizer, a falling-film countercurrent medium-pressure decomposing tower and a heater, an ammonium carbamate condenser, an ammonium carbamate separator, a three-stage medium-pressure absorption tower and an evaporative ammonia refrigeration recoverer, a liquid ammonia buffer tank, an inert gas scrubber, a tail-gas ammonia cleaning fine purifier, a low-pressure decomposing tower and a heater, a dimethyl liquid preheater, a horizontal low-pressure absorber, a falling film type pre-evaporator, a one-stage evaporator and a one-stage evaporative condenser, a two-stage evaporator and a two-stage evaporative condenser, and a process wastewater desorption and hydrolysis tower are sequentially connected behind the urea synthesizer in sequence. The energy-saving urea production system has the advantages of low investment, low energy consumption, simple operation, high elasticity and the like, thereby the process technology has considerable economic benefit and social benefit.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

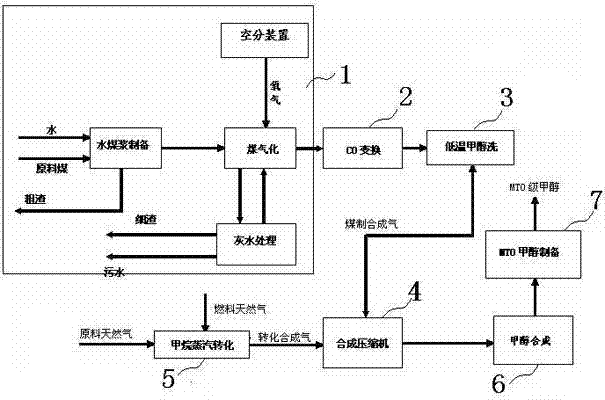

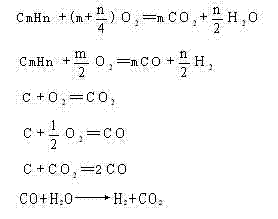

Method for synthesizing methanol through low-carbon technology

ActiveCN102531835AReduce the burden onImprove conversion rateHydrogenOrganic compound preparationChemistryDry gas

The invention relates to a manufacturing process of methanol and in particular to a method for synthesizing methanol through a low-carbon technology. The method is characterized by comprising the following steps: mixing synthesis gas transformed from methane gas and the synthesis gas produced by coal gasification in proportion, performing a synthesis compression process on the mixed gas, and then enabling the mixed gas to enter into a methanol reactor for producing the methanol, wherein the methane gas is natural gas or oil-associated gas or coal bed gas or coke oven gas or blast furnace gas or oil refining dry gas and other CH4-rich mixed gas; the hydrogen-carbon ratio or the ratio of H:C is the proportion of (H2-CO) / (CO+CO2) in the synthesis gas, and H2, CO and CO2 gas components are calculated by percentage content; and the production of the synthesis gas by coal gasification comprises the production of raw gas and the regulation process of the hydrogen-carbon ratio. The method for synthesizing the methanol through the low-carbon technology, provided by the invention, has the advantages of high production efficiency, high utilization rate of resources and low emission of carbon dioxide.

Owner:SHAANXI YANCHANG PETROLEUM GRP

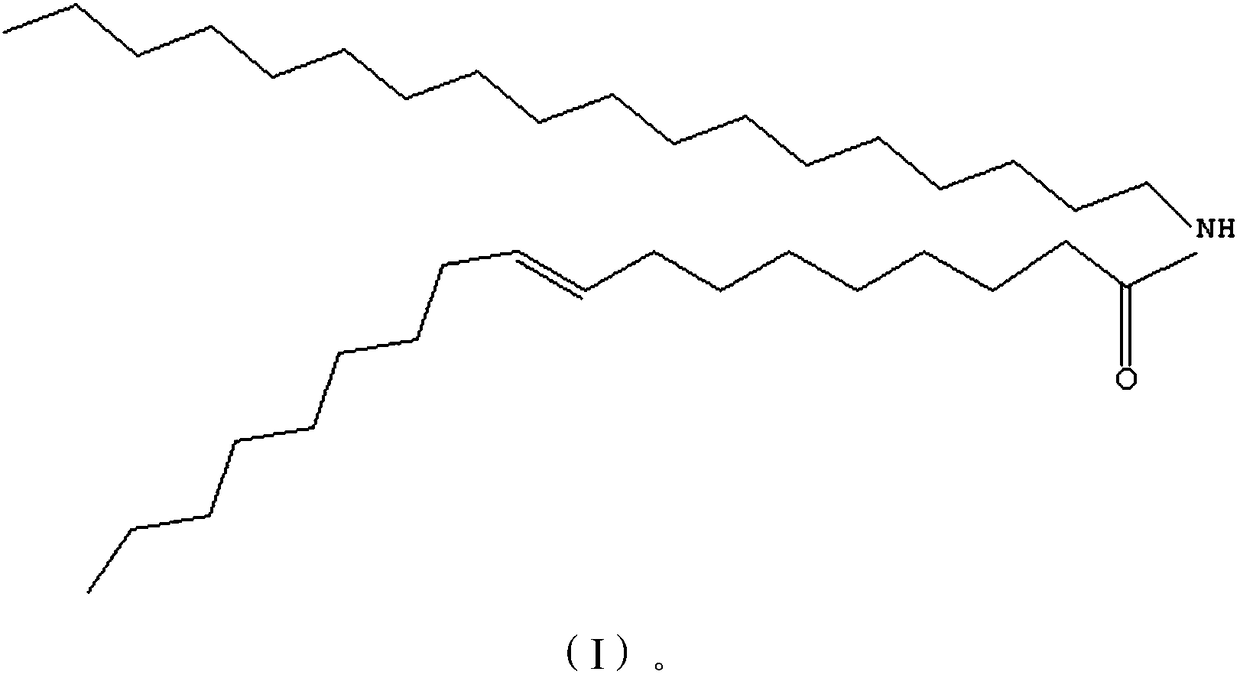

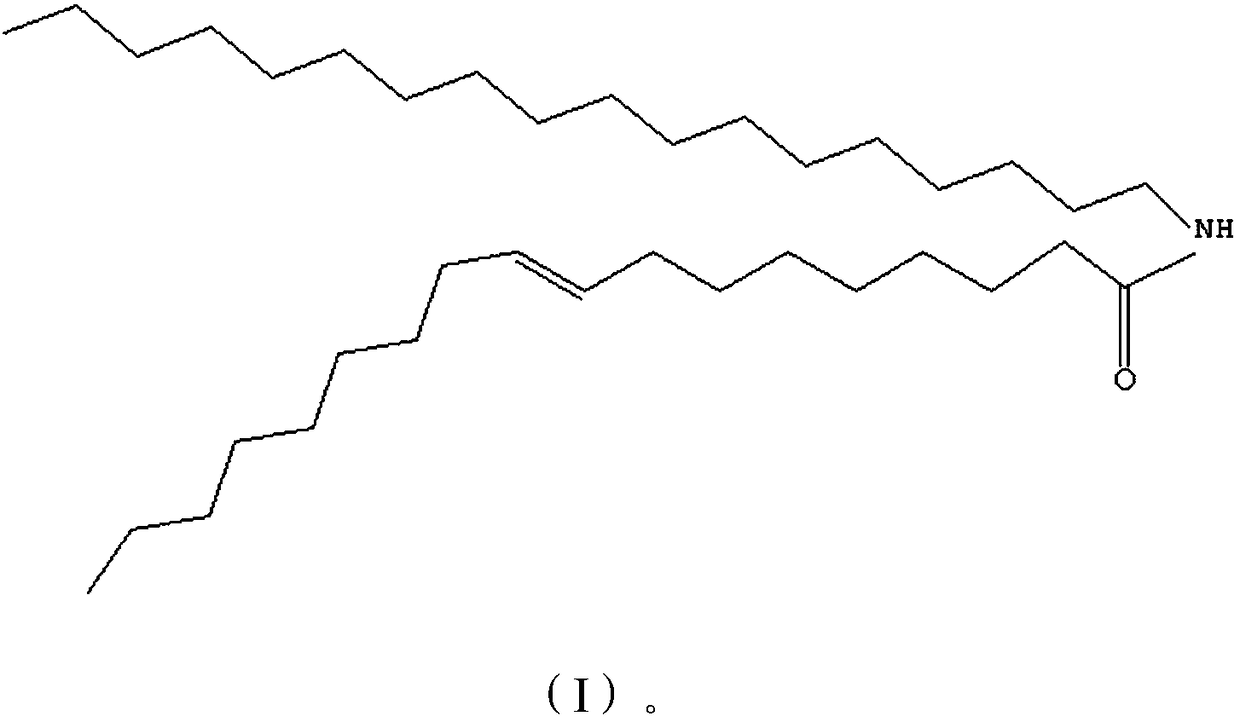

Octadecyl oleamide, preparation method and application thereof

InactiveCN109336780AHigh synthetic conversion rateReduce energy consumptionOrganic compound preparationCarboxylic acid amides preparationAntistatic agentTemperature resistance

The invention discloses octadecyl oleamide and preparation thereof. The octadecyl oleamide has a structure shown by the general formula (I) in the specification. The octadecyl oleamide provided by theinvention is a plastic additive which is multifunctional, high-efficiency, high-temperature resistant, low-migration and wide in range of application, can be used as one or more of an anti-blocking agent, a slipping agent, an antistatic agent, a heat stabilizer, a release agent and an anti-wear agent in plastics, and has the effects of lubricating an opening and improving the properties of a plastic product, such as scratch resistance, wear resistance, static electricity resistance, high-temperature resistance and the like.

Owner:广州禾工材料科技有限公司

Production of low-free TDI polyurethane curing agent, curing agent therefrom and its products

A low-free radical TDI polyurethane curing agent, its production and product are disclosed. The process is carried out by putting tolylene-diisoester cyanate, solvent S and catalyst A into reactor, adding into antioxidant and long-chain alcohol, agitating in reactor, heating, keeping temperature, inspecting NCO value, adding into phase-transferring solvent X while reaching NCO value to 20-40%, adding into catalyst B till reaching NCO value to 10-15, adding into inhibitor to stop reaction, adding into solvent S, decreasing pressure, distilling and removing phase-transferring solvent X. It's cheap and convenient.

Owner:BEIJING ZHANCHEN CHEM +2

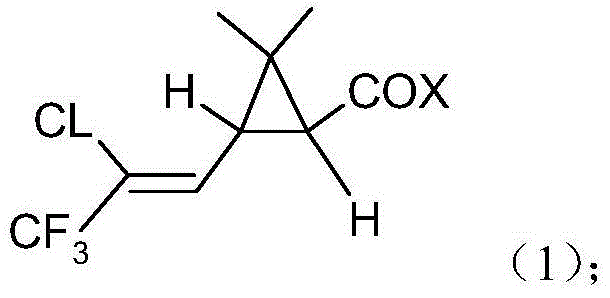

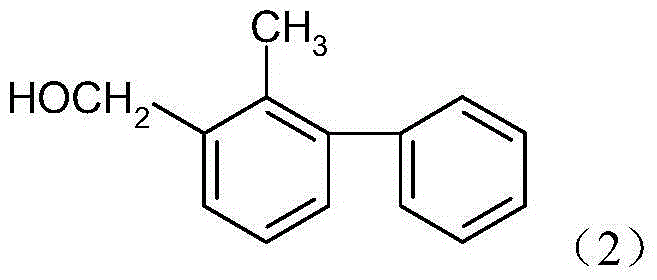

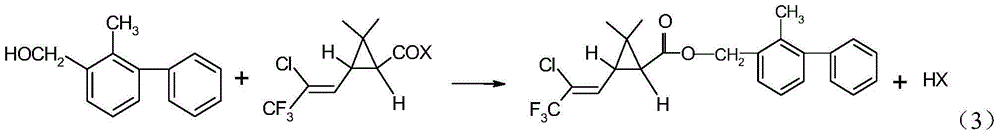

Method for producing bifenthrin with clean synthesizing process

InactiveCN104628569AHigh synthetic conversion rateHigh product contentPreparation from carboxylic acid halidesHalogenSolvent

The invention provides a method for producing bifenthrin with a clean synthesizing process. According to the method, 3-(2-chloro-3,3,3-trifluoro-1-allyl)-2,2-dimethylcyclopropane formyl halide and 2-methyl-3-biphenylmethanol are adopted to directly react in one solvent or mixed solvent of more than two solvents in favor of overflow of halogen hydride, halogen hydride generated in the reaction is removed from tail gas in time by means of negative pressure, and the product is directly cooled and crystallized to obtain bifenthrin. The reaction equation is as shown in a formula (3), wherein X is Cl or Br. The production method has the characteristics of high product content, simple process flow, small output of the 'Three Wastes' and the like, and accords with the requirement for clean production.

Owner:JIANGSU YANGNONG CHEM +1

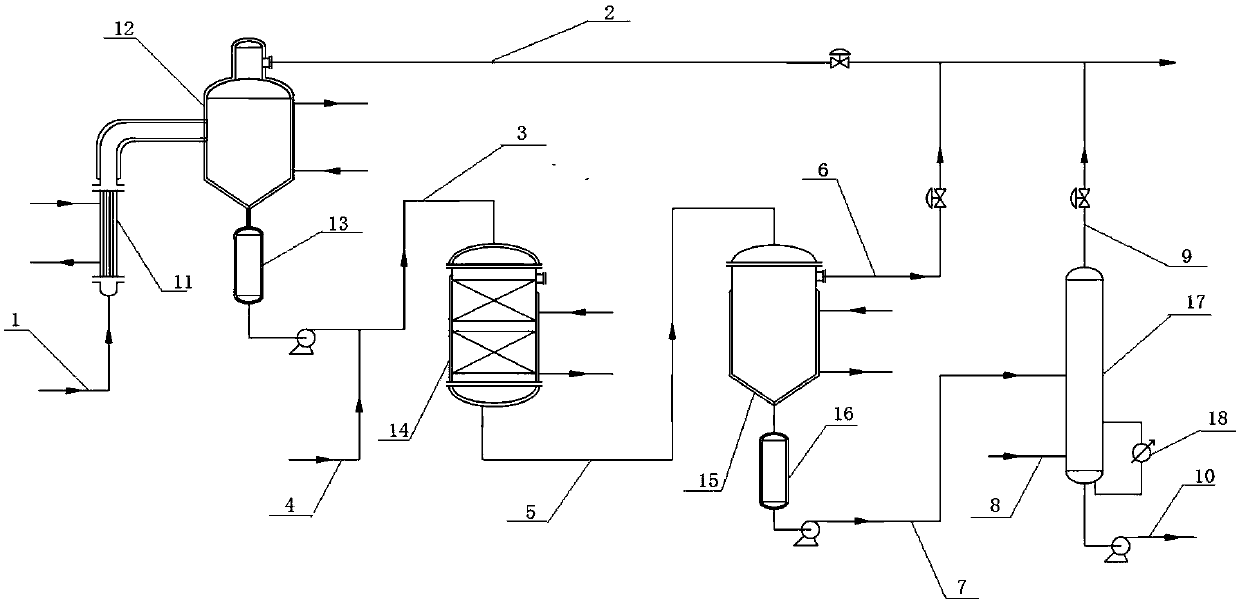

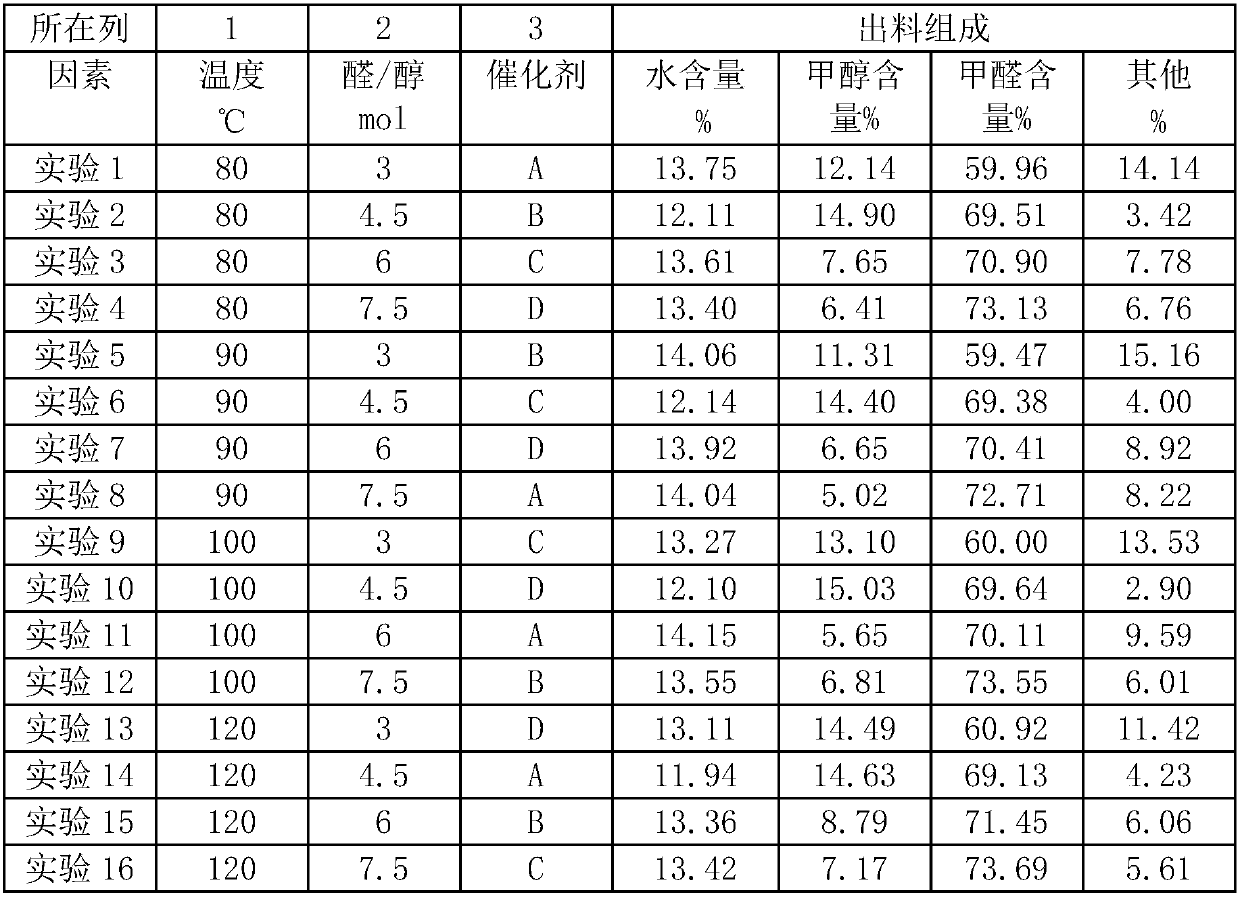

Preparation process of formaldehyde alcoholic solution for polymethoxy dimethyl ether production

InactiveCN107652169ARealize the controllability of the degree of aggregationReduce decompositionOrganic chemistryOrganic compound preparationHigh concentrationDecomposition

Aiming at the problem that the acquisition of formaldehyde with low water content decides the feasibility of DMMn synthesis and directly influences the product synthesis conversion rate, aldehyde canbe concentrated to 85 percent through a vacuum concentration system, the water content in the formaldehyde is dewatered to 0.5 to 3 percent in a dewatering tower, methyl alcohol with a low boiling point is condensed with the formaldehyde, the polymerization degree controllability of the formaldehyde in a liquid phase is realized, and a formaldehyde alcoholic solution with a polymerization degree nbeing equal to 3 to 10 is obtained, so that the most suitable reaction raw material-the formaldehyde alcoholic solution with a low water content is found for polymethoxy dimethyl ether synthesis. Theformaldehyde vacuum concentration system is combined with a stripping tower principle, so that the formaldehyde alcoholic solution with the low water content is prepared, the water content in the reaction system is reduced, the product decomposition is avoided, the DMMn synthesis conversation rate is efficiently improved, meanwhile, the risk of polymerization during a high-concentration formaldehyde concentration process is avoided due to the introduction of the formaldehyde, the concentration temperature is reduced, the generation of formic acid is reduced, and an advantageous effect is achieved on separating a follow-up polymethoxy dimethyl ether product.

Owner:无锡赫利邦化工科技有限公司

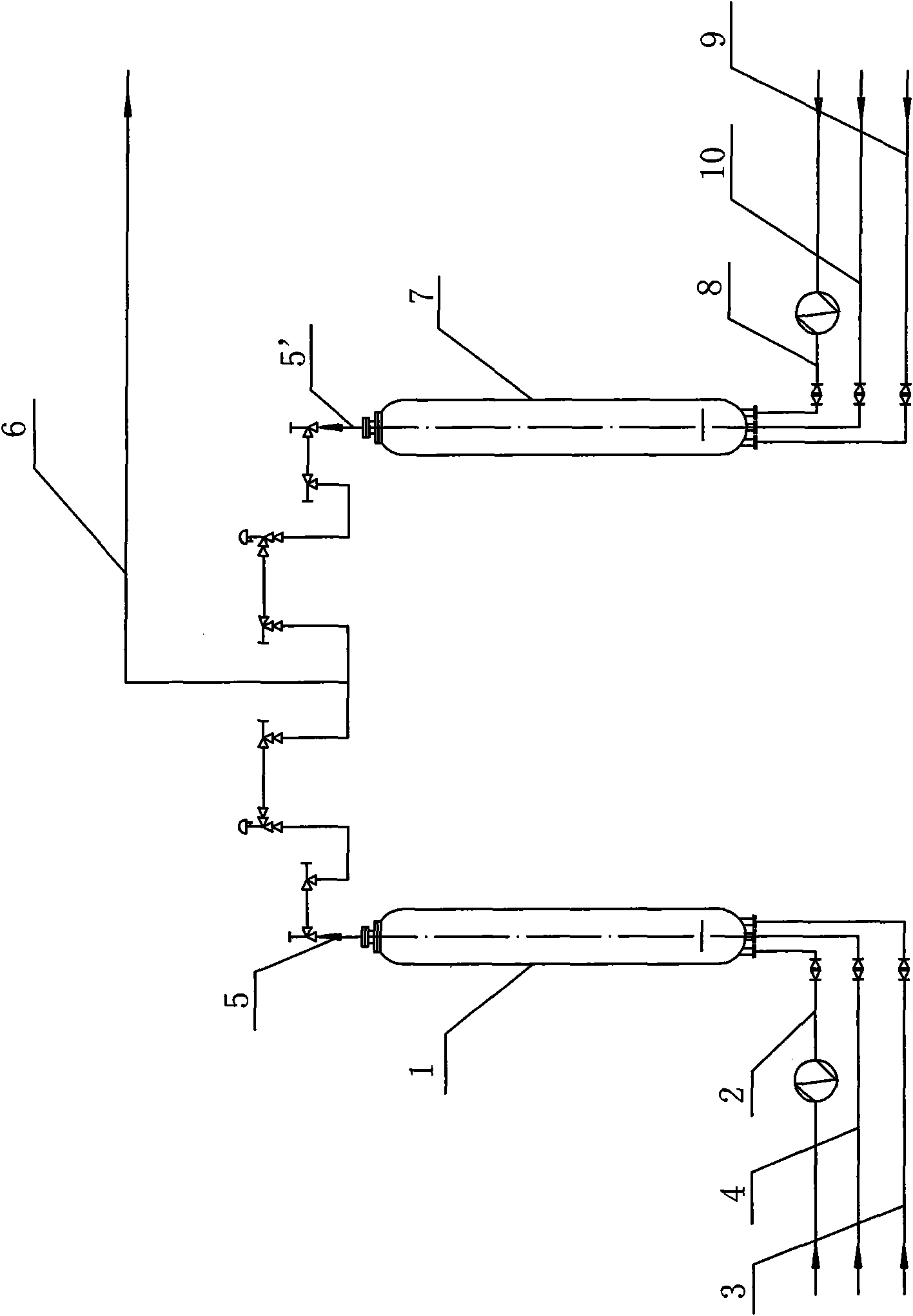

Dual-tower parallel urea synthesizing device

InactiveCN101659633AReduce production intensityHigh synthetic conversion rateUrea derivatives preparationProductsTowerUltimate tensile strength

The invention relates to a dual-tower parallel urea synthesizing device, comprising two urea synthesizing towers. Each urea synthesizing tower is communicated with respective liquid ammonia feed pipe,carbon dioxide feed pipe and nail liquid feed pipe; discharge pipes are respectively arranged at the tops of the two urea synthesizing towers; two discharge pipes are connected together and then communicated with a discharge main pipe; and the size and the specification of the two urea synthesizing towers are same. The dual-tower parallel urea synthesizing device reduces the production strength of the urea synthesizing towers, prolongs the stay time of materials in the synthesizing towers, improves the urea synthesizing conversion rate and the yield capacity, has less investment and quick extension and production, saves labor force and matched facilities, allows to repair synthesizing towers having faults or stop the overhaul of any one synthesizing tower under the condition of not stopping production and has simples operation and flexible adjustment.

Owner:HUAQIANG CHEM GRP

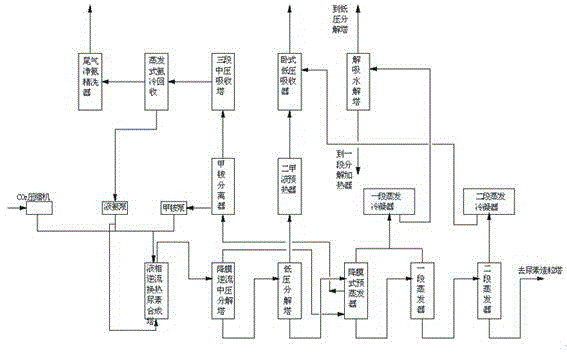

An energy-saving urea production system and its production process

ActiveCN104829494BReduce energy consumptionEasy to operateUrea derivatives preparationOrganic compound preparationDesorptionAmmonium carbamate

The invention belongs to the field of urea preparation, and particularly relates to an energy-saving urea production system and a production process thereof. The system comprises a CO2 compressor, an ammonium carbamate pump, a liquid ammonia pump and a urea synthesizer. The system is characterized in that the CO2 compressor is connected with the ammonium carbamate pump and the liquid ammonia pump, the liquid ammonia pump is connected with the urea synthesizer, a falling-film countercurrent medium-pressure decomposing tower and a heater, an ammonium carbamate condenser, an ammonium carbamate separator, a three-stage medium-pressure absorption tower and an evaporative ammonia refrigeration recoverer, a liquid ammonia buffer tank, an inert gas scrubber, a tail-gas ammonia cleaning fine purifier, a low-pressure decomposing tower and a heater, a dimethyl liquid preheater, a horizontal low-pressure absorber, a falling film type pre-evaporator, a one-stage evaporator and a one-stage evaporative condenser, a two-stage evaporator and a two-stage evaporative condenser, and a process wastewater desorption and hydrolysis tower are sequentially connected behind the urea synthesizer in sequence. The energy-saving urea production system has the advantages of low investment, low energy consumption, simple operation, high elasticity and the like, thereby the process technology has considerable economic benefit and social benefit.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

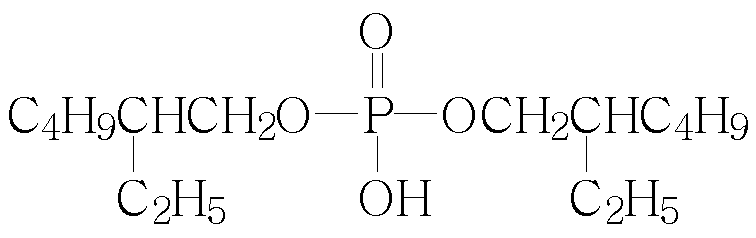

Synthesis method of phosphodiesterase (2-ethylhexyl) ester

PendingCN103224515AHigh synthetic conversion rateEasy to synthesizeGroup 5/15 element organic compoundsPhosphodiesteraseAlcohol

The present invention relates to a synthesis method of phosphodiesterase (2-ethylhexyl) ester, including the following steps of mixing the phosphorus oxychloride and the 2-ethylhexyl alcohol at molar ratio of 1: (1.9 -2.0), adding the calcium-magnesium catalyst, stirring, controlling the pressure in -0.02Mpa to -0.03Mpa, the dropping rate of phosphorus oxychloride at 100+ / -5kg / h and the temperature at 55+ / -5 DEG C, adding the phosphorus oxychloride for continuous reaction for 4 to 5 hours; maintaining the negative pressure above 700mmHg, heating up to 70+ / -2 DEG C to continue reacting for 4 to 5 hours to obtain solids; basifying, acidifying to obtain the crude ester; distilling: heat-distilling the crude ester, collecting the fraction of between 170 and 175 DEG C, to obtain the phosphodiesterase (2-ethylhexyl) ester. The preparation method provided by the invention simplifies the synthesis process, with simple method easy to operate, available raw materials and low cost. Moreover, the synthetic conversion rate of phosphodiesterase (2-ethylhexyl) ester obtained by the method is up to 88%, and the product quality is stable with good effect for use, various technical indicators reaching the standard.

Owner:天津市联瑞阻燃材料有限公司

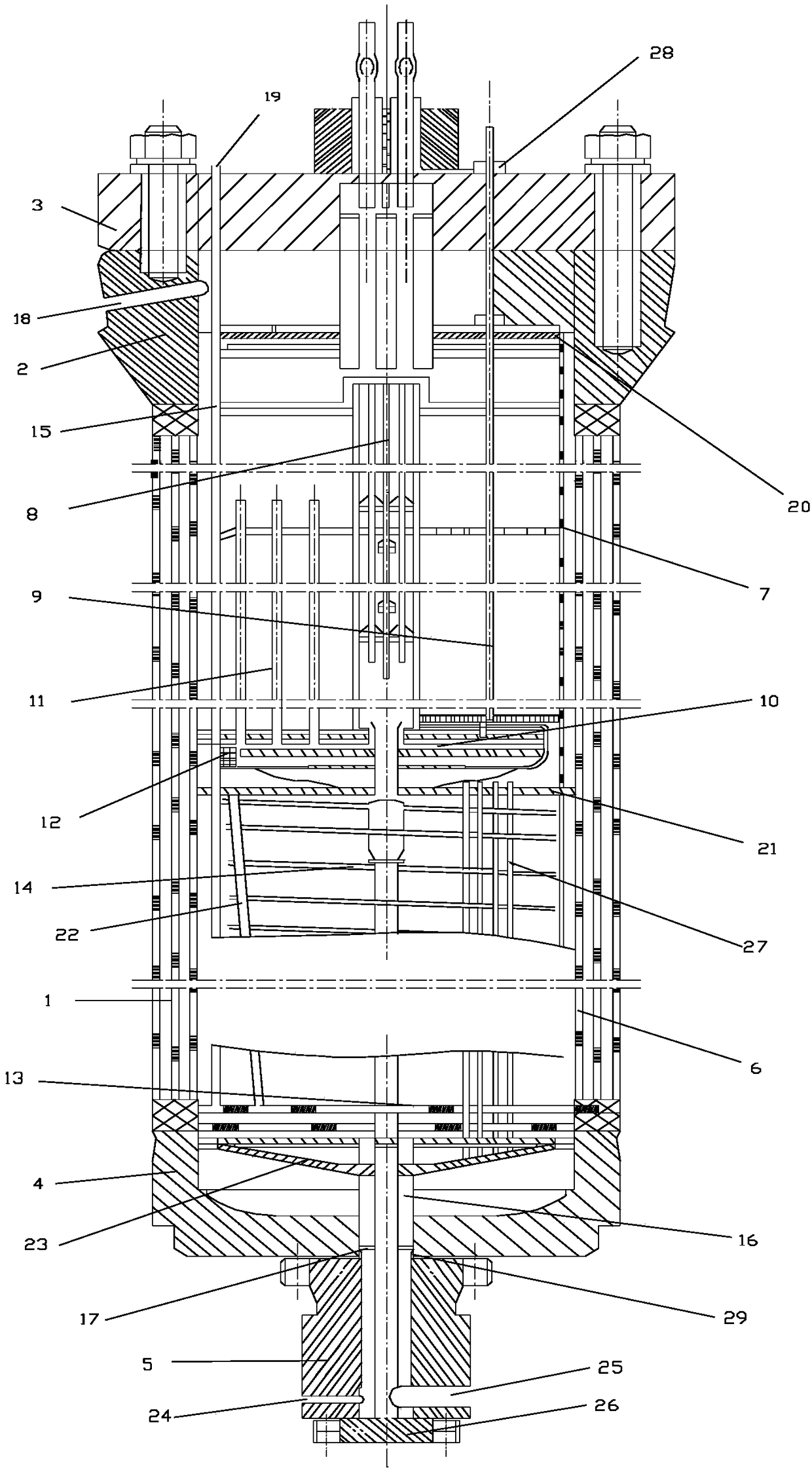

Reaction tower for ammonia synthesis

InactiveCN108910915AUniform mass transferReduce mass transfer resistanceBulk chemical productionAmmonia preparation/separationSmall footprintEngineering

The invention relates to a reaction tower for ammonia synthesis. Main components comprise an outer cylinder, a top cover, a tower top flange, a bottom cover, a tower bottom assembly, an inner cylinder, a catalyst basket, a casing pipe mechanism, a heat exchanger, heat exchange pipes, a circulation pipe, a product output pipe and a filter membrane. The upper end of the outer cylinder is connected to the top cover. The upper end of the top cover is connected to the tower top flange. The top cover is provided with a raw material inlet. The lower end of the outer cylinder is connected to the bottom cover. The lower end of the bottom cover is connected to the tower bottom assembly. The outer cylinder wraps the inner cylinder. The upper part of the inner cylinder is provided with the catalyst basket. The casing pipe mechanism is arranged at the lower end of the catalyst basket. The heat exchanger is arranged at the lower end of the inner cylinder. The heat exchanger is provided with the heatexchange pipes spirally and inclinedly distributed, the heat exchanger is provided with a circulation pipe, a product output pipe is arranged at the lower end of the heat exchanger and the filter membrane is arranged in the product output pipe. The reaction tower has the advantages of high ammonia synthesis conversion rate, compact structure, small floor space, neat internal structure, convenientmaintenance, energy saving, high ammonia separation efficiency and high ammonia quality.

Owner:张波

D-phenylglycine methyl ester phosphate crystal, preparation method and solution

PendingCN111909046AHigh synthetic conversion rateImprove buffering effectOrganic compound preparationOrganic chemistry methodsO-Phosphoric AcidPhosphate crystals

The invention discloses a D-phenylglycine methyl ester phosphate crystal, a preparation method and a solution, and the preparation method comprises the following steps: step a, adding Dphenylglycine and methanol into a reaction tank, uniformly stirring, and feeding phosphoric acid; step b, after the phosphoric acid is fed, carrying out reflux reaction; c, after the reflux reaction in the step b isfinished, carrying out vacuum dehydration, and then repeating the following operations for n times: adding methanol, continuously carrying out the reflux reaction, and carrying out vacuum dehydrationafter the reflux reaction is finished; and d, adjusting the pH value to be acidic, adding the Dphenylglycine methyl ester phosphate seed crystal for crystallization, and drying to obtain the Dphenylglycine methyl ester phosphate crystal. The problems of low subsequent enzymatic synthesis conversion rate and severe corrosion to equipment in the related art are solved.

Owner:TIANJIN UNIV

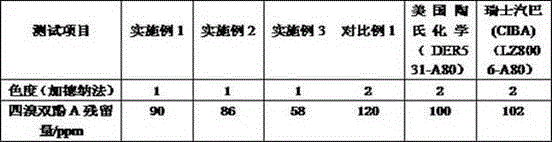

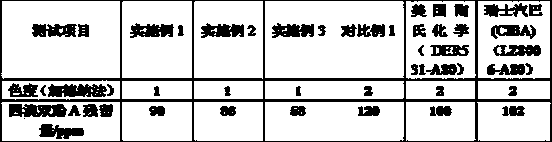

A kind of preparation method of special brominated epoxy resin for copper clad laminate and the product thereof

The invention discloses a preparation method of brominated epoxy resin special for a copper-clad plate and a product prepared by using the preparation method. The preparation method comprises the following steps of by adopting bisphenol A liquid epoxy resin and tetrabromobisphenol A as raw materials, adding a catalyst for reaction to obtain intermediate resin; adding the bisphenol A liquid epoxy resin again for polymerization and chain extension to obtain the target brominated epoxy resin. The brominated epoxy resin prepared by using the preparation method provided by the invention has the advantages of high purity, low product chrominance and stable product quality.

Owner:建滔(广州)电子材料制造有限公司

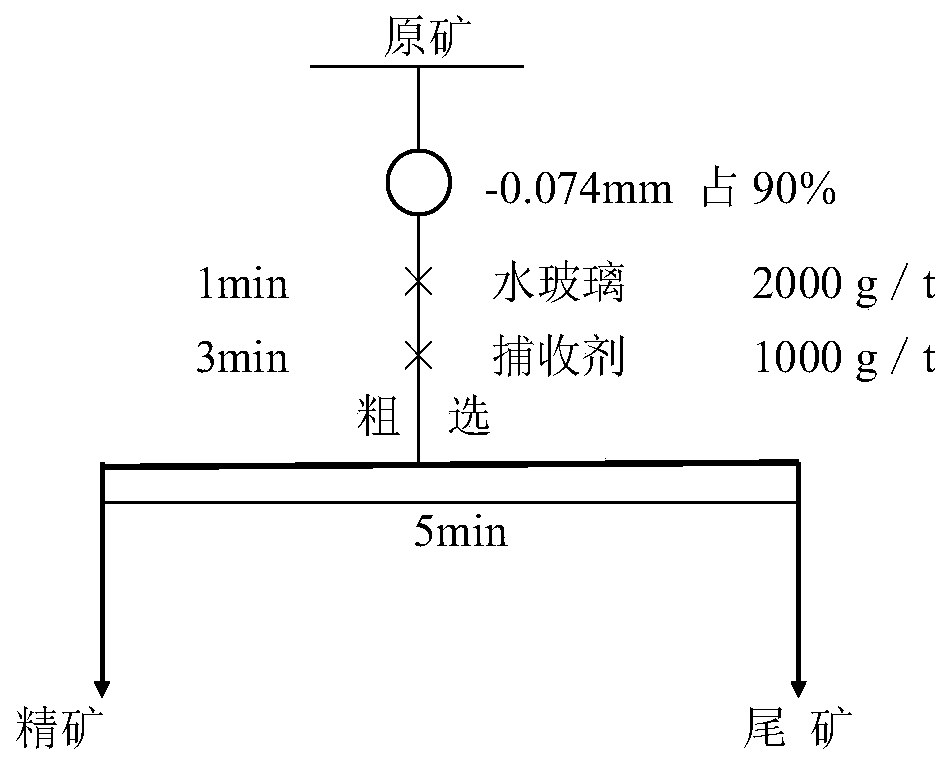

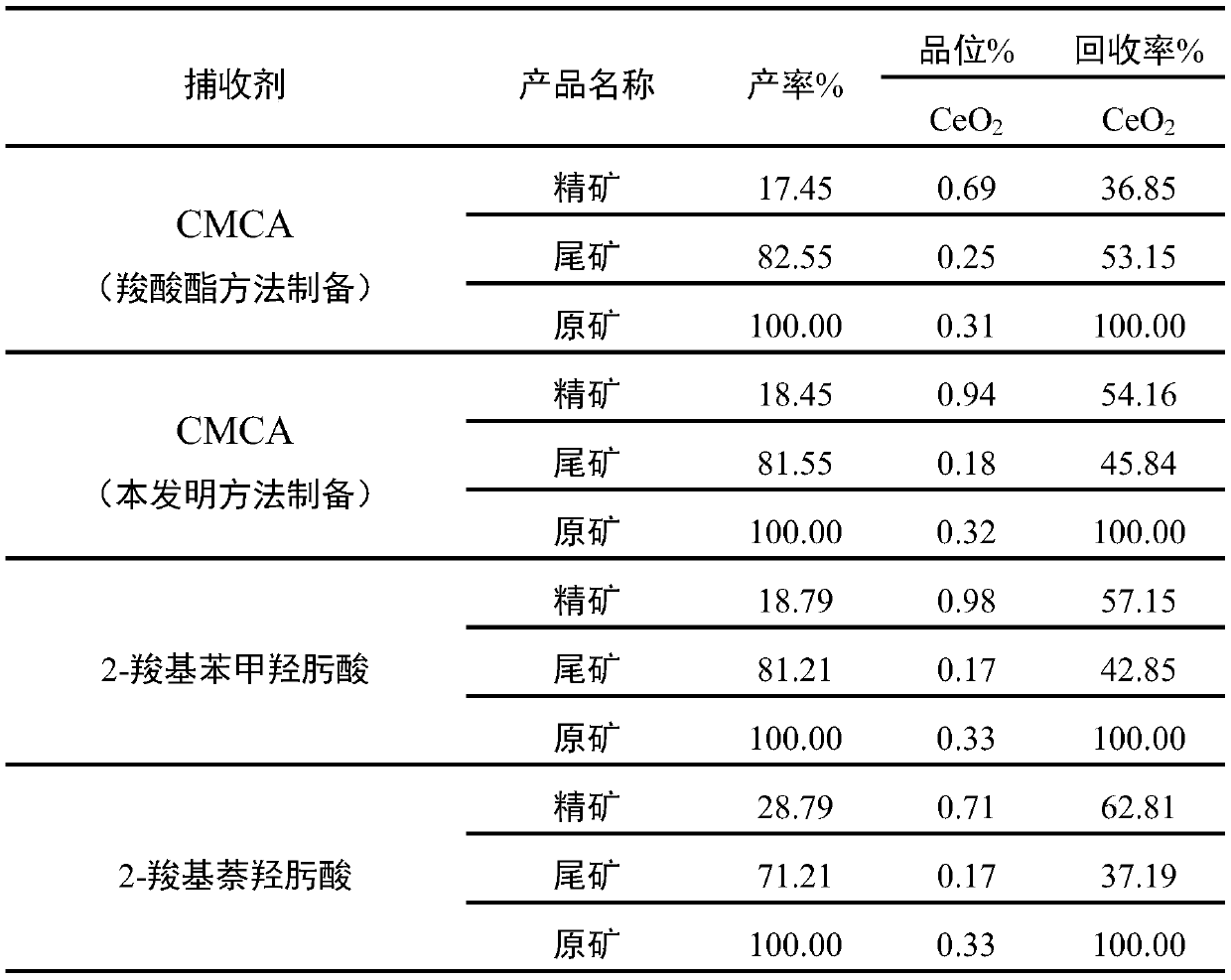

Preparation method of hydroxamic acid

ActiveCN111269146AEmission reductionHigh reaction conversion rateOrganic chemistryFlotationHydroxizinumHydroxylamine

The invention provides a preparation method of hydroxamic acid. The preparation method comprises the following steps: reacting acid anhydride with hydroxylamine under the catalysis of alkali, and acidifying after the reaction is completed, wherein the acid anhydride is C4-C12 cycloalkane fatty acid anhydride or aromatic acid anhydride. According to the preparation method, hydroximation reaction can be realized without heating, the reaction conditions are mild, side reactions are few, the purity of the obtained product is high, and the concentrate product obtained by flotation is high in recovery rate and grade. Secondly, the synthesis conversion rate of the product is high, the raw material consumption ratio is reduced, the synthesis cost is greatly reduced, the alkali consumption in the preparation process of the method is greatly reduced, the acid required in the subsequent acidification process is also reduced, the generated waste residue sodium chloride is reduced and the wastewater discharge amount is reduced by about 50% or above.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

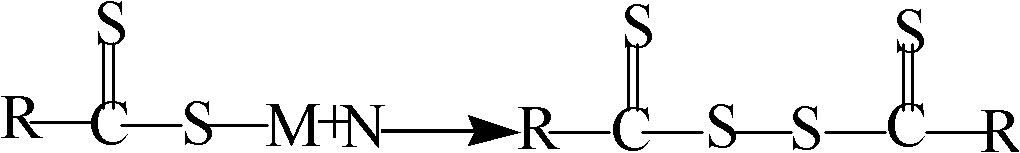

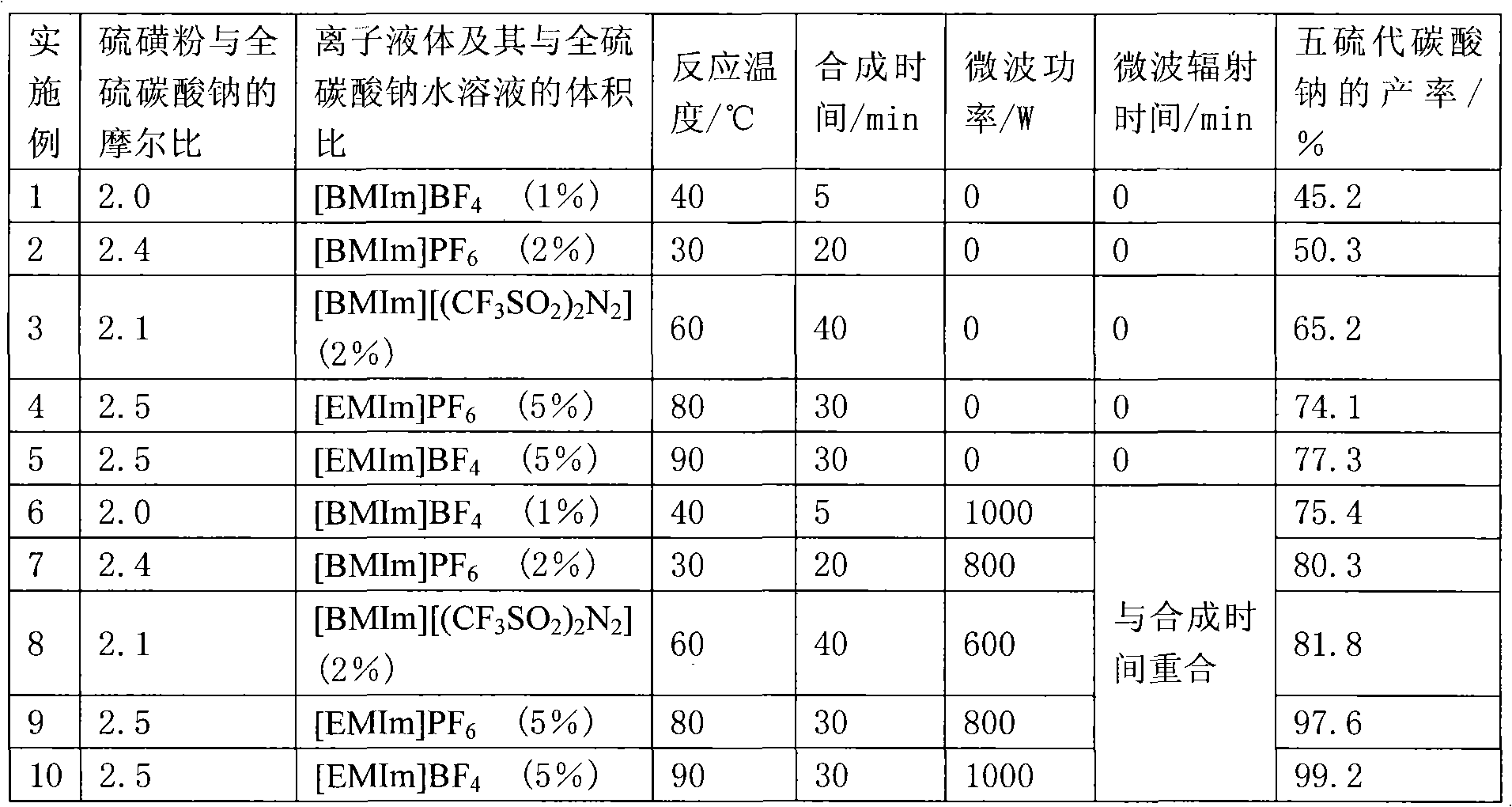

Synthetic method of sodium pentathiosulfate

InactiveCN101302017AImprove conversion rateReduce contentWater/sewage treatmentAlkali metal carbonatesMicrowaveSodium tetrathiocarbonate

The invention relates to a five-sodium tetrathiocarbonate synthetic method. The method uses sodium thiocarbonate and sulphur powder as raw material. Excess sulphur powder is used to synthesize five-sodium tetrathiocarbonate rapidly in high efficiency under the synergetic action of a phase transfer catalyst ionic liquid and microwaves. The ionic liquid can be used as a phase transfer catalyst, a solubilizer and a microwave absorbent; and a subsidiary product of four-sodium tetrathiocarbonate has small amount. The method is simple in operation and easy to separate and realize continuous production. The five-sodium tetrathiocarbonate synthetic method provides a new idea and a new method for the five-sodium tetrathiocarbonate synthesis.

Owner:CHONGQING UNIV

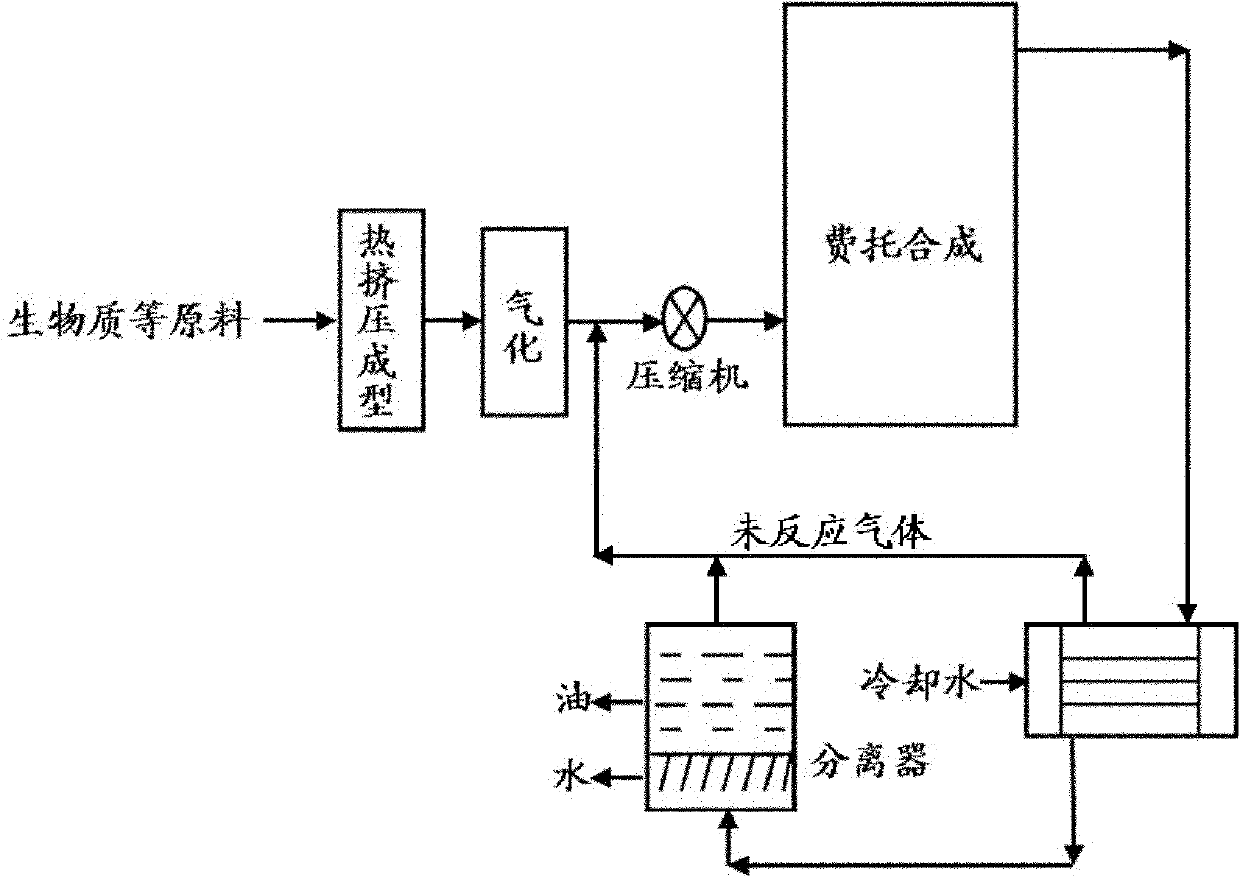

Method for preparing biological fuel oil

ActiveCN102140361BStable gasification processEasy to operateWaste based fuelLiquid hydrocarbon mixture productionSludgeHigh carbon

The invention discloses a method for biological fuel oil. In the method, biological matter, mineral matter, household garbage and urban sludge are used as raw materials, and the raw materials are dehydrated and carbonized into a high-carbon content solid with a certain shape and size by a thermal-extrusion molding technique and then are prepared into the novel biological fuel oil by adopting a gasification process and Fischer-Tropsch synthesis. The method has the advantages of wide range of the raw materials, low production cost and high gasification and Fischer-Tropsch synthesizing efficiency and is easy to control the production process, and the biological fuel oil has the advantages of high yield and good quality and is suitable for industrial production.

Owner:海南环宇新能源有限公司

A kind of production method of adenosine triphosphate (ATP)

InactiveCN104762347BHigh purityHigh synthetic conversion rateSugar derivativesChemical industryFiltrationSeparation technology

A production method of adenosine triphosphate (ATP) mainly includes following steps: (1) treatment of beer yeast; (2) fermentation to extract a conversion enzyme; (3) plate-frame pressure filtration; (4) micro-filtration; (5) fermentation to synthesize the ATP; (6) nano-filtering desalination; (7) resin adsorption; (8) resin washing elution; (9) ultra-filtration to remove protein and heat source; (8) precipitation with ethanol; and (9) a drying operation. In the invention, due to a high-efficient energy-saving membrane separation technology, after the step of fermentation to synthesize the ATP, the purity of the conversion enzyme can be increased through the micro-filtration, thereby increasing synthetic conversion rate of the ATP. During the separation and purification process of a fermentation synthetic liquid of the ATP, the nano-filtration is employed for removing inorganic salt nutrients added during the synthesis process so that the ATP adsorption capacity of ion exchange resin can be increased. By means of the ultra-filtration to remove protein and heat source, the purity of the ATP is increased. The production method can increase the production capacity, recycle rate and purity of the ATP, can reduce the consumption of chemical reagents, is simplified in processes, can reduce pollution emission and the like.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

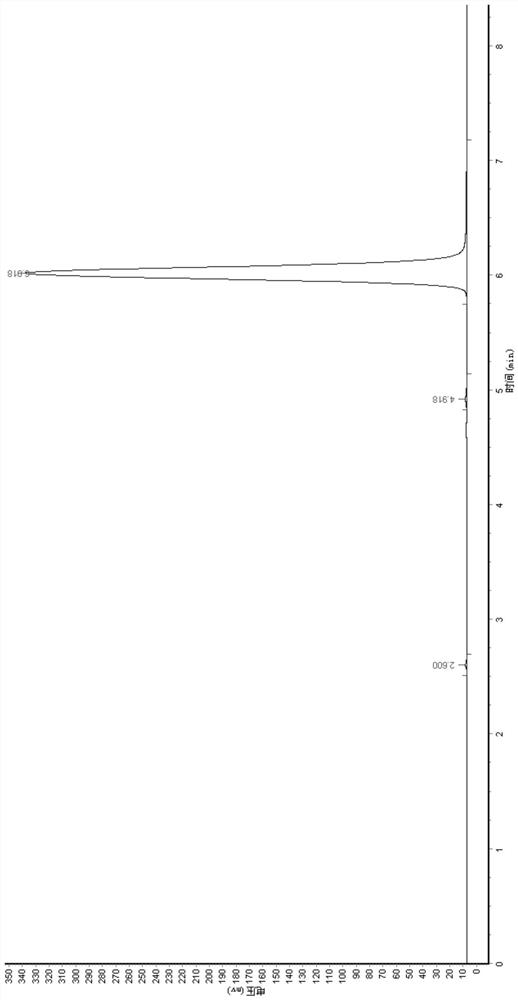

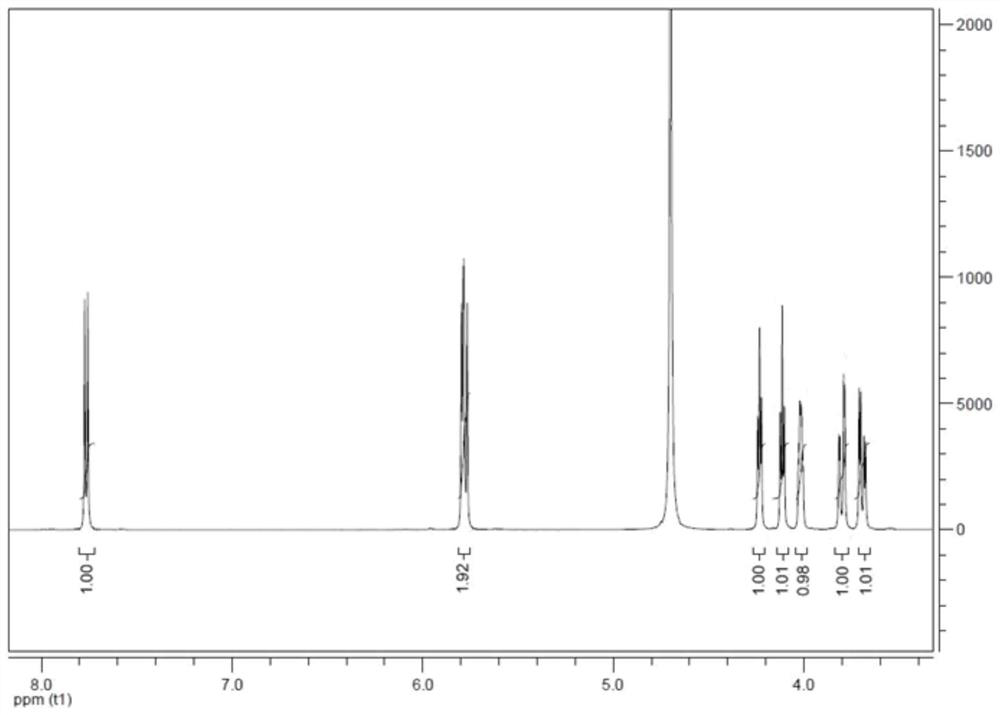

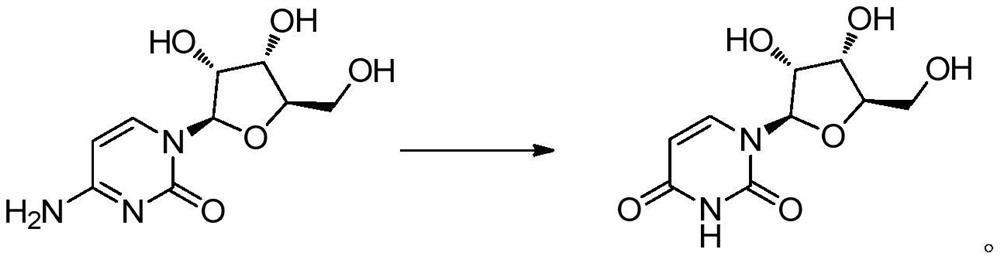

Synthesis process of uridine

ActiveCN113735926AThe synthesis process is simpleReduce manufacturing costSugar derivativesSugar derivatives preparationOrganic acidCytosine

The invention discloses a synthesis process of uridine, and belongs to the technical field of organic synthesis. The process comprises the following steps of uniformly mixing cytidine serving as a main raw material with water, controlling the temperature to be 10-60 DEG C, respectively adding a nitrous acid reagent and inorganic acid or organic acid, carrying out heat preservation reaction for 1-10 hours, ending the reaction after the raw material is added, controlling the pH value to be 1-4 after the reaction is completed, carrying out reduced pressure concentration to obtain a uridine concentrated solution, dropwise adding an alcohol solvent into the uridine concentrated solution, and crystallizing to obtain the product uridine. The process is easy to operate, thorough in reaction and high in reaction speed, and the synthesis period is greatly shortened. In addition, the conversion rate of the process is up to 90% or above, the yield is up to 80% or above, and the purity is greater than 99.5%.

Owner:江苏香地化学有限公司

Preparation method of brominated epoxy resin special for copper-clad plate and product prepared by using preparation method

The invention discloses a preparation method of brominated epoxy resin special for a copper-clad plate and a product prepared by using the preparation method. The preparation method comprises the following steps of by adopting bisphenol A liquid epoxy resin and tetrabromobisphenol A as raw materials, adding a catalyst for reaction to obtain intermediate resin; adding the bisphenol A liquid epoxy resin again for polymerization and chain extension to obtain the target brominated epoxy resin. The brominated epoxy resin prepared by using the preparation method provided by the invention has the advantages of high purity, low product chrominance and stable product quality.

Owner:建滔(广州)电子材料制造有限公司

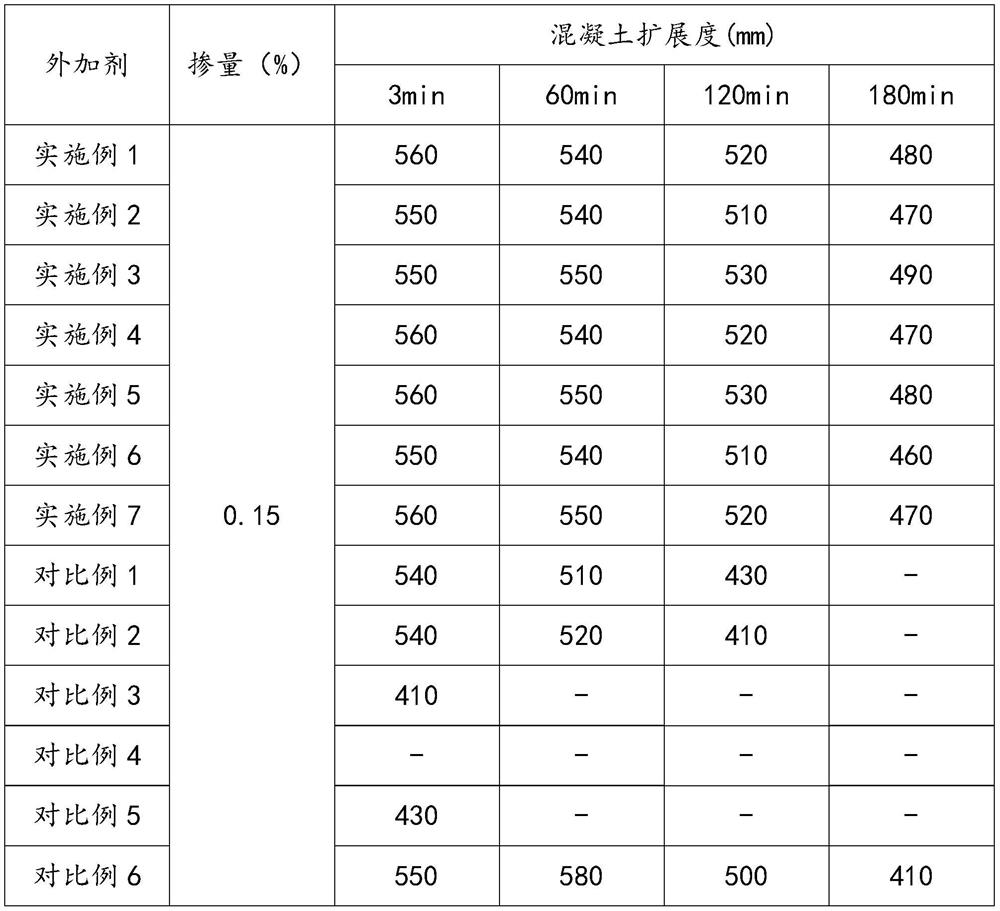

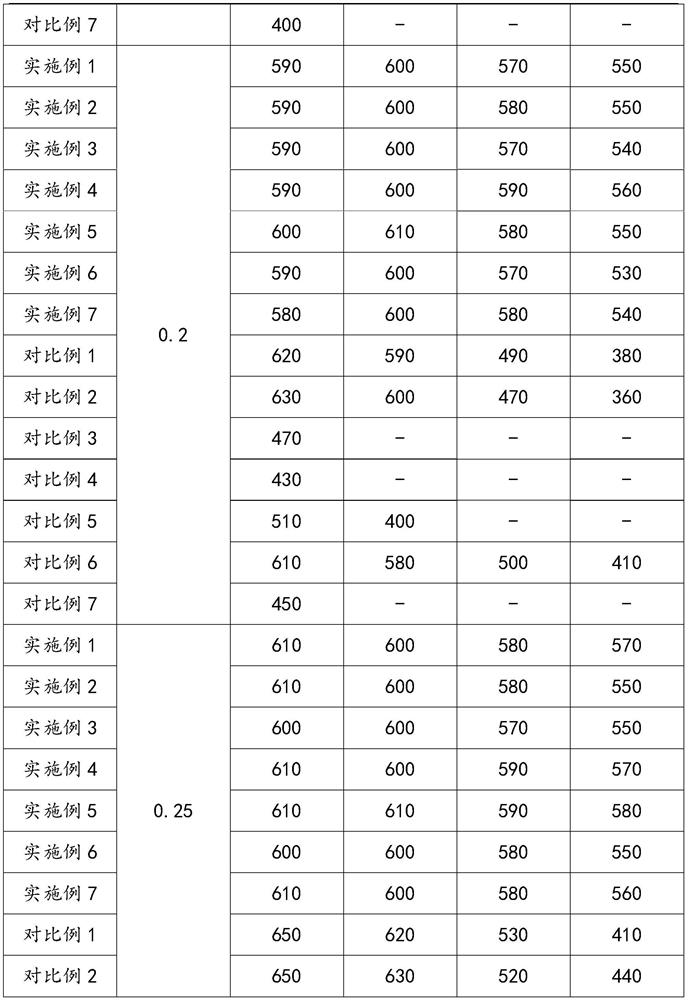

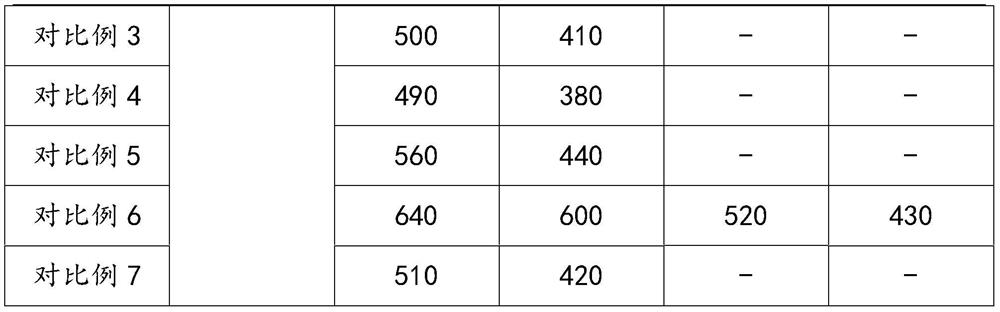

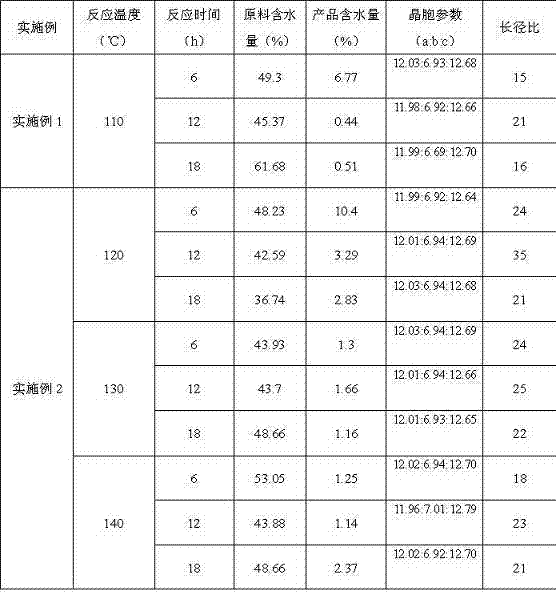

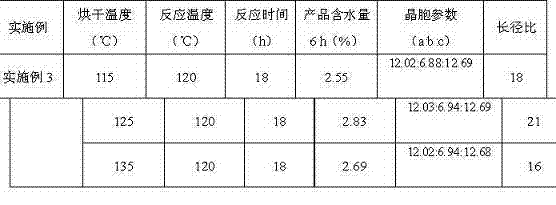

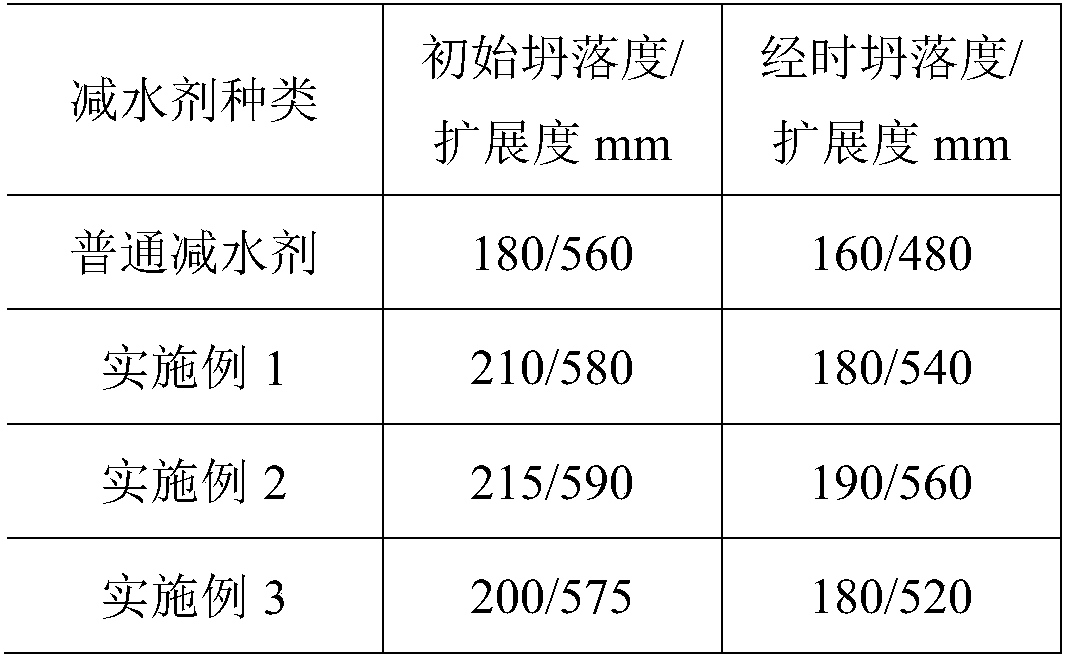

Concrete water reducing agent and preparation method thereof

PendingCN112708050AGood slump performanceImprove conversion rateHydration reactionPolyethylene glycol

The invention relates to the technical field of building admixtures, in particular to a concrete water reducing agent and a preparation method thereof. The concrete water reducing agent comprises a photopolymerizable monomer selected from alkoxy polyethylene glycol esterification intermediates, and a photoinitiator which is benzoin. According to the concrete water reducing agent provided by the invention, the alkoxy polyethylene glycol esterification intermediate is adopted, slump retaining performance and water reducing performance can be both considered, meanwhile, the reaction can be carried out at normal temperature or low temperature, monomer prepolymerization is directly initiated through light irradiation, the polymerization rate is greatly increased, the synthesis conversion rate is increased, and the sensitivity is reduced; and in addition, the sulfonic acid group is added, so that the surfaces of cement particles can be stably adsorbed, the hydration reaction can be effectively delayed, the dispersing and slump retaining effects in concrete with medium and low strength grades are enhanced, and the market application prospect is extremely wide.

Owner:重庆建研科之杰建材有限公司 +1

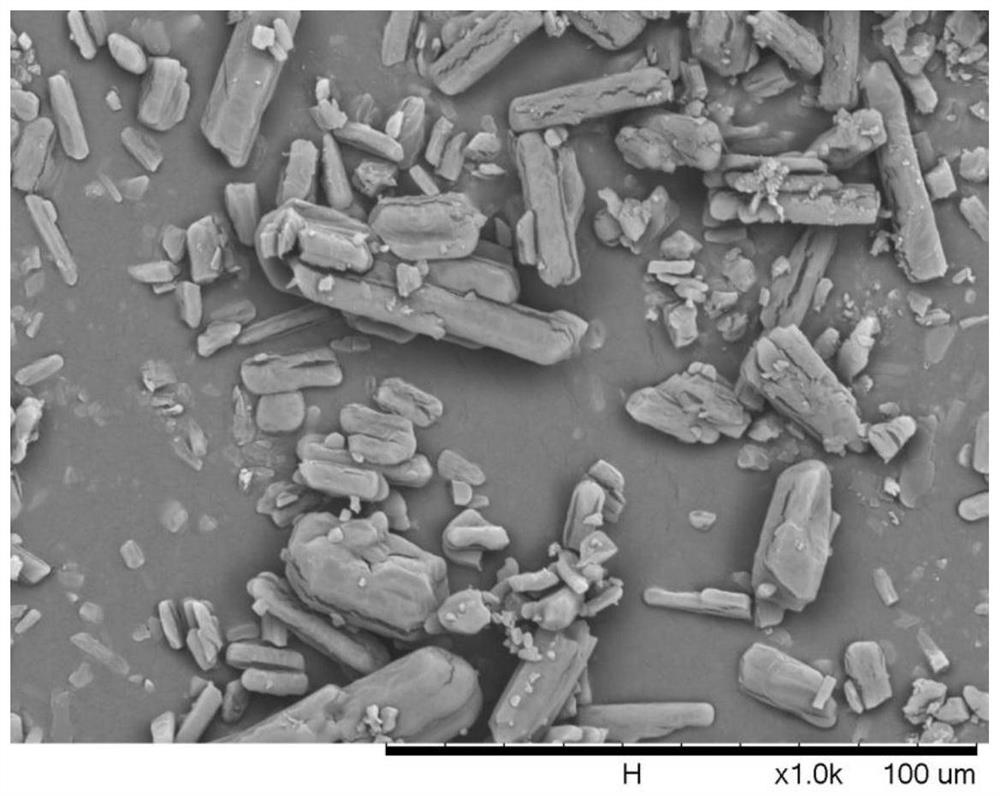

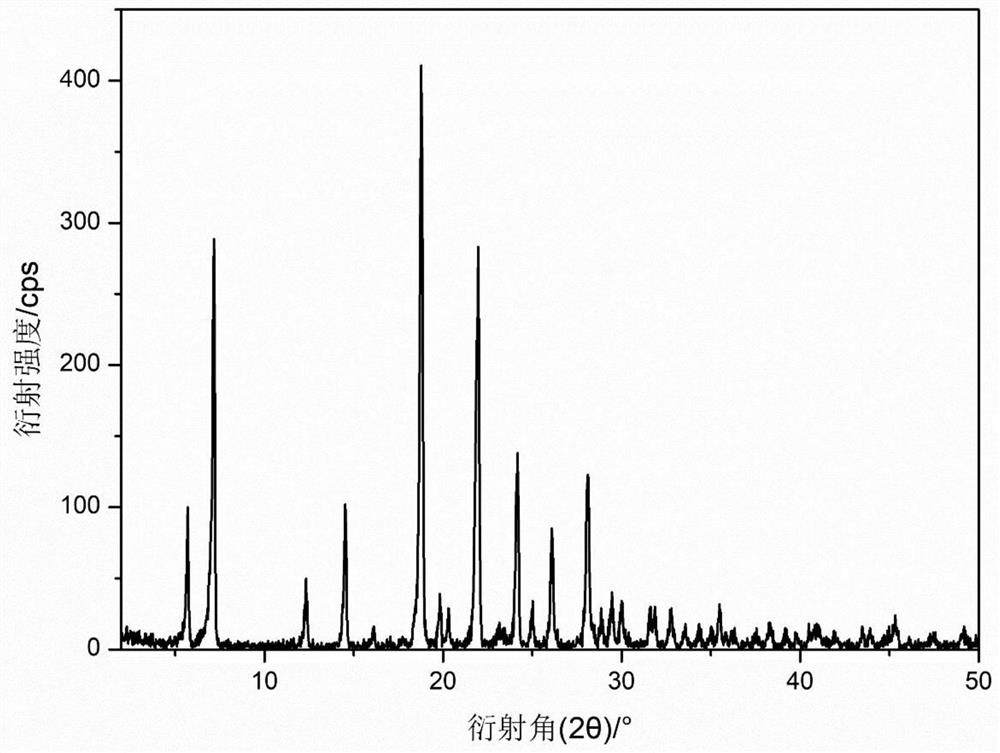

Preparation method for cubic boron nitride

InactiveCN110255512AHigh synthetic conversion rateEasy to synthesizeNitrogen compoundsHexagonal boron nitrideBoron nitride

The invention discloses a preparation method for cubic boron nitride. The preparation method for cubic boron nitride comprises the following steps: purifying industrial grade borax and urea through recrystallization to obtain analytically-pure industrial grade borax and urea; dehydrating and drying the borax; adding borax as a cosolvent; putting the above substances into a ball mill for uniform mixing; feeding the formed mixture into a crucible, and putting the crucible in a high temperature furnace to prepare boron nitride powder; grinding the boron nitride powder and performing washing and purification to obtain hexagonal boron nitride powder; and drying the hexagonal boron nitride powder and performing pressing to form a green body; pressing the green body at a temperature of 1300 DEG C and a pressure of 4 GPa for 20 min to obtain a pre-pressed synthetic rod; crushing the pre-pressed synthetic rod and then performing screening to obtain a sieved material, and carrying out annealing for 50 min to obtain pretreated hexagonal boron nitride powder; mixing the pretreated hexagonal boron nitride powder and a metal nitride catalyst to prepare a mixture, and pressing the mixture at a temperature of 30 DEG C and a pressure of 25 GPa to form a mixture synthetic rod; and carrying out high-temperature and high-pressure sintering at a temperature of 1300-1600 DEG C and a pressure of 4-7 GPa to prepare a cubic boron nitride crystal. The preparation method of the invention has the advantages of rapid conversion, low cost, high utilization rate of raw materials, etc.

Owner:大连新翔工业材料有限公司

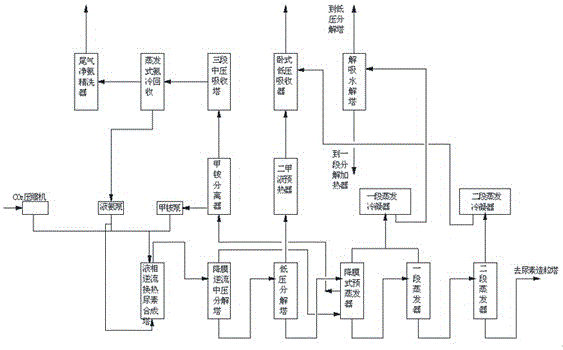

Improved low-energy-consumption CO2 stripping method urea process

PendingCN114409573AReduce loadGood for water controlUrea derivatives preparationProductsFluid phasePhysical chemistry

According to the technical scheme, urea synthesis liquid is divided into two parts, one part of urea synthesis liquid is fed into a high-pressure CO2 stripping tower in a high-pressure decomposition and recovery system to be subjected to high-pressure CO2 stripping, and the other part of urea synthesis liquid is fed into a high-pressure CO2 stripping tower in a high-pressure decomposition and recovery system to be subjected to high-pressure CO2 stripping; the other part of the urea synthesis liquid is fed into a medium-pressure decomposition tower of the medium-pressure decomposition recovery system for medium-pressure decomposition, and a medium-pressure gas phase and a medium-pressure decomposition liquid phase are obtained. High-pressure stripping liquid flowing out of the bottom of the high-pressure CO2 stripping tower and the other part of urea synthesis liquid are decompressed and then are respectively fed into the middle section and the upper section of a medium-pressure decomposition tower for medium-pressure gas-liquid separation, and medium-pressure decomposition liquid led out of the bottom of the medium-pressure decomposition tower is fed into a low-pressure decomposition tower for low-pressure decomposition. The method is simple in process, easy to transform, capable of further saving energy and reducing consumption, capable of improving productivity and low in investment and operation cost.

Owner:WUHUAN ENG

Synthesis method of pentaerythritol polyoxyethylene ether stearate

PendingCN111592648AHigh synthetic conversion rateHigh catalytic activityPolymer sciencePtru catalyst

The invention discloses a synthesis method of pentaerythritol polyoxyethylene ether stearate. The synthesis method comprises the following steps: 1, heating melting: adding stearic acid, pentaerythritol polyoxyethylene ether and a fixed superacid catalyst to a reaction kettle, and heating melting, the molecular weight of pentaerythritol polyoxyethylene ether being 5000-9000; stirring until the materials in the reaction kettle are completely molten; 2, esterification reaction: continuously carrying out esterification reaction on the material obtained in the step 1 in the reaction kettle until the acid value of the material is less than or equal to 15mg. KOH / g through sampling test; and 3, cooling and filtering: taking out the material obtained in step 2 from the reaction kettle, cooling, and filtering to obtain pentaerythritol polyoxyethylene ether stearate. According to the method, the synthesis conversion rate of pentaerythritol polyoxyethylene ether stearate is effectively increased,and the production requirements of enterprises are met.

Owner:JIAHUA CHEM MAOMING

A kind of preparation method of rhenium hexafluoride

ActiveCN110589893BAvoid disproportionation reactionsPrevent restoreRhenium compoundsHexafluoridePhysical chemistry

The invention relates to a preparation method of rhenium hexafluoride, which belongs to the technical field of fluorine chemical industry. In this method, the rhenium powder and nitrogen trifluoride mainly generate a mixture of rhenium hexafluoride and rhenium heptafluoride by adjusting the fluorination reaction conditions, and the disproportionation reaction of other valence rhenium fluorides can be basically avoided; The reaction conditions are such that rhenium heptafluoride reacts with rhenium powder to form rhenium hexafluoride, preventing rhenium heptafluoride and rhenium hexafluoride from being reduced to rhenium fluoride in a lower valence state. The method of the invention has the advantages of simple operation, safety and economy, high synthesis conversion rate, and the prepared rhenium hexafluoride has a purity higher than 90 wt%.

Owner:PERIC SPECIAL GASES CO LTD

Process for synthesizing organic polymer flocculant by controlling concentration of hydrochloric acid

InactiveCN103724484ALower synthesis costEasy to operateWater/sewage treatment by flocculation/precipitationWater bathsFiltration

The invention discloses a process for synthesizing an organic polymer flocculant. The process comprises the following steps: (a) measuring certain quantities of polyacrylamide, formaldehyde, dimethylamine and hydrochloric acid for later use, wherein in percentage by mass, the hydrochloric acid accounts for 1.0 percent of the total mass; (b) placing the formaldehyde in a reaction container; (c) slowly adding the polyacrylamide and a catalyst into the reaction container and stirring with adding; (d) then placing the reaction container into water bath to heat; (e) next, adding the dimethylamine into the reaction container; (f) cooling and then adding the hydrochloric acid to carry out quaternization; (g) finally, obtaining the target product by carrying out evaporation concentration and filtration. According to the invention, the qualified organic polymer flocculant can be successfully synthesized; the synthesis process is simple; the synthesis conversion rate is high; the process is convenient for workers to operate; synthesis cost of the organic polymer flocculant is greatly reduced; in the synthesizing process, by controlling the concentration of the hydrochloric acid, reaction efficiency and product performance are further improved.

Owner:刘萍

Method for automatically controlling and adjusting sodium hydrosulfite synthesis system pressure and backflow quantity

ActiveCN102491284BHigh synthetic conversion rateProcess ScienceThiosulfates/dithionites/polythionitesAutomatic controlControl system

The invention relates to a method for automatically controlling and adjusting sodium hydrosulfite synthesis system pressure and backflow quantity, which adopts an automatic control system to adjust the sodium hydrosulfite synthesis system pressure and the backflow quantity, has scientific process steps and process parameters and effectively resolves the problems of uncertainty and instability of pressure and backflow quantity in the manual control and adjustment of the sodium hydrosulfite synthesis system. The method enables sodium hydrosulfite combining reaction to be good in stability, even in backflow quantity, stable in sodium hydrosulfite quality and low in production cost.

Owner:烟台市金河保险粉厂有限公司

Method for preparing hemihydrate calcium sulfate crystal whisker

InactiveCN102268722BHigh whisker purityHigh aspect ratioPolycrystalline material growthFrom normal temperature solutionsHemihydrate Calcium SulfateSulfate

Owner:中国人民解放军第三五九医院 +1

A kind of polycarboxylate superplasticizer masterbatch with sulfonic acid phosphoric acid group double chain transfer effect

A polycarboxylic acid water reducer master batch having a sulpho-phospho double chain transferring function is disclosed. Raw materials include 345-350 parts of a polyether macromonomer, 32.0-40.0 parts of acrylic acid, 3.0-8.0 parts of a sulpho chain transferring agent, 1.0-5.0 parts of a phospho chain transferring agent, 2.0-5.0 parts of hydrogen peroxide and 0.35-0.75 part of vitamin C, with the balance being water, and with the total mass of the raw materials being 1000 parts. A polycarboxylic acid water reducer synthesized from the master batch can be polymerized at a low temperature, carboxyl, sulpho and phosphor groups are alternatively arranged, adsorbability and anchoring capability are stronger, and a product has characteristics of a high water reduction rate and wide adaptability. The modified master batch is suitable for a situation that a grinding aid adopted in a cement preparing process contains a retarder or salt electrolyte the competitive adsorbability of which is higher than competitive adsorbability of the carboxyl and thiol.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com