Method for preparing biological fuel oil

A bio-fuel and biological technology, which is applied in the field of high-efficiency preparation of new bio-fuel, can solve the problems of low yield and low quality of bio-fuel, and achieve the effects of high gasification conversion rate, convenient operation and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

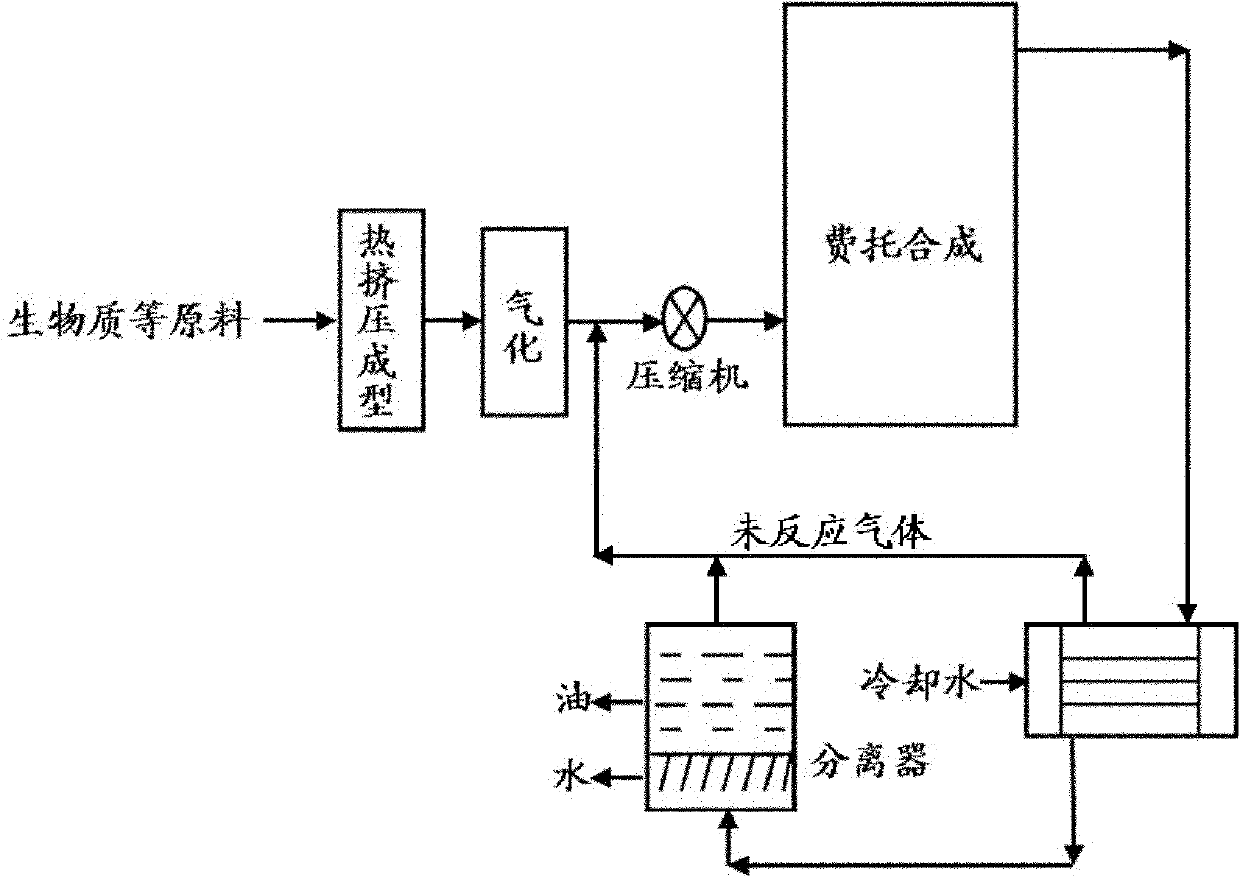

[0027] In the first step, the wheat straw is put into a hot extrusion molding machine, and a solid with a carbon content of 99.9wt% is produced under the conditions of 720°C and 350MPa.

[0028] In the second step, the solid matter is put into the gasifier and gasified at 870°C to produce a synthesis gas containing 62.4vol% hydrogen and 29.2vol% carbon monoxide (the remaining components are CO 2 and CH 4 Wait).

[0029] In the third step, the synthetic gas is purified and compressed and introduced into the Fischer-Tropsch synthesis tower to produce biofuel with 1.5 vol% C2-C4 hydrocarbons, 4.2 vol% C5-C8 hydrocarbons, and 93.6 vol% hydrocarbons above C9.

Embodiment 2

[0031] In the first step, the straw is put into a hot extrusion molding machine, and a solid with a carbon content of 52.1 wt% is obtained under the conditions of 1180° C. and 0.0001 MPa.

[0032] In the second step, the solid matter is put into the gasifier and gasified at 1200°C to produce a synthesis gas containing 80.0vol% hydrogen and 18.9vol% carbon monoxide (the remaining components are CO 2 and CH 4 Wait).

[0033] In the third step, the synthetic gas is purified and compressed and introduced into the Fischer-Tropsch synthesis tower to produce biofuel with 1.0 vol% C2-C4 hydrocarbons, 3.0 vol% C5-C8 hydrocarbons, and 94.1 vol% hydrocarbons above C9.

Embodiment 3

[0035] In the first step, the bagasse is put into a hot extrusion molding machine, and a solid with a carbon content of 73.5wt% is prepared under the conditions of 350° C. and 56 MPa.

[0036] In the second step, the solid matter is put into the gasifier and gasified at 180°C to produce a synthesis gas containing 24.0vol% hydrogen and 40.0vol% carbon monoxide (the remaining components are CO 2 and CH 4 Wait).

[0037] In the third step, the synthetic gas is purified and compressed and introduced into the Fischer-Tropsch synthesis tower to produce biofuel with 3.0 vol% C2-C4 hydrocarbons, 3.9 vol% C5-C8 hydrocarbons, and 90.0 vol% hydrocarbons above C9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com