Method for synthesizing methanol through low-carbon technology

A technology for synthesizing methanol and technology, which is applied in the field of methanol synthesis with low-carbon technology, can solve the problems of affecting conversion efficiency and difficult cost control, and achieve the effects of increasing economic benefits, significant energy saving effects, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

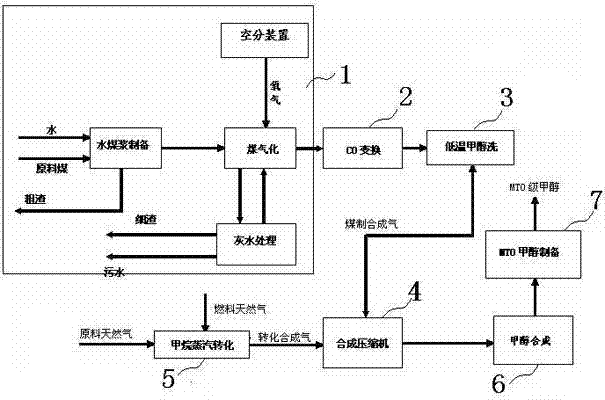

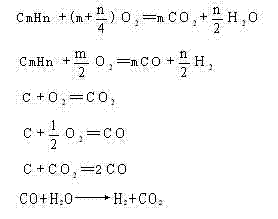

[0040] Such as figure 1 As shown, the principle of process 1 for methanol production in coal chemical industry is: the crude gas generated by coal gasification is transformed through CO conversion process 2, that is, CO+H 2 O—→H 2 +CO 2 The transformation reaction produces H 2 +CO+CO 2 Completion: The crude water gas from the gasification scrubber is separated by the gas-liquid separator to remove the moisture entrained in the gas, and then divided into two streams, one part enters the raw material gas preheater and exchanges heat with the shift gas to about 305°C, enters the shift furnace, and is separated from itself The carried water vapor undergoes a partial shift reaction under the action of the sulfur-tolerant shift catalyst; the high-temperature shift gas exiting the shift furnace passes through the feed gas preheater for heat exchange, and then enters the medium-pressure steam generator to produce 2.5MPa(G) saturated steam by-product. The gas at the outlet of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com