Preparation method of brominated epoxy resin special for copper-clad plate and product prepared by using preparation method

A technology for brominated epoxy resin and liquid epoxy resin, which is applied to the preparation method and the product field thereof, can solve the problems of unstable process and general indicators, and achieves good process stability, stable product quality and high response. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

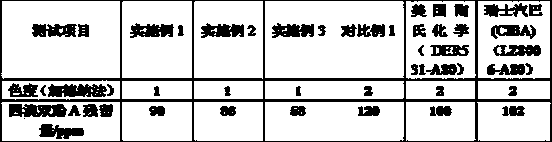

Examples

Embodiment 1

[0027] Embodiment 1, the preparation method of brominated epoxy resin special for copper clad laminates of the present invention is as follows:

[0028]Put bisphenol A type liquid epoxy resin into the reaction kettle, under the protection of nitrogen, heat to 78 ° C, start stirring, put tetrabromobisphenol A, bisphenol A type liquid epoxy resin and tetrabromobisphenol A by weight Feed at a ratio of 1:1; heat up to 88°C within 30 minutes after the feed is complete, and add 0.08% tetrabutylammonium bromide, methyltriphenylammonium bromide and polyethylene glycol ( Weight ratio 0.2:1:0.07) mixture; heat and control the temperature at 168 ° C, react for 1 hour to obtain an intermediate resin; add 80% of the amount of tetrabromobisphenol A to the reactor again Bisphenol A liquid epoxy resin , control the reaction temperature at 148°C, react under stirring for 13min to obtain brominated epoxy resin; stop nitrogen flow, add tetrabromobisphenol A addition of 73% acetone to dissolve t...

Embodiment 2

[0030] Embodiment 2, the preparation method of brominated epoxy resin special for copper clad laminates of the present invention is as follows:

[0031] Put bisphenol A type liquid epoxy resin into the reaction kettle, under the protection of nitrogen, heat to 82 ℃, start stirring, put into tetrabromobisphenol A, bisphenol A type liquid epoxy resin and tetrabromobisphenol A by weight Feed at a ratio of 1.4:1; heat up to 92°C within 60 minutes after the feed, add 0.08% tetrabutylammonium bromide, methyltriphenylammonium bromide and polyethylene glycol ( weight ratio 0.4:1:0.09) mixture; heat and control the temperature at 172°C, react for 2 hours to obtain an intermediate resin; add 82% bisphenol A liquid epoxy resin in the amount of tetrabromobisphenol A to the reaction kettle , control the reaction temperature at 152°C, react under stirring for 17min to obtain brominated epoxy resin; stop nitrogen flow, add tetrabromobisphenol A addition of 76% acetone to dissolve the prepa...

Embodiment 3

[0033] Embodiment 3, the preparation method of brominated epoxy resin special for copper clad laminates of the present invention is as follows:

[0034] Put bisphenol A type liquid epoxy resin into the reaction kettle, under the protection of nitrogen, heat to 80 ℃, start stirring, put tetrabromobisphenol A, bisphenol A type liquid epoxy resin and tetrabromobisphenol A by weight Feed at a ratio of 1.2:1; heat up to 90°C within 40 minutes after the feed is complete, and add 0.08% tetrabutylammonium bromide, methyltriphenylammonium bromide and polyethylene glycol ( Weight ratio 0.3:1:0.08) mixture; heat and control the temperature at 170°C, react for 2 hours to obtain an intermediate resin; add 81% bisphenol A liquid epoxy resin in the amount of tetrabromobisphenol A to the reaction kettle , control the reaction temperature at 150°C, react under stirring for 15 minutes to obtain brominated epoxy resin; stop nitrogen flow, add tetrabromobisphenol A addition of 73% acetone to di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com