Lithium ion secondary battery and anode thereof

A secondary battery and lithium-ion technology, applied in secondary batteries, battery electrodes, battery components, etc., can solve problems such as ineffective formation of LiF protective layer, easy damage to the surface structure of high-nickel active materials, and potential safety hazards , achieve good physical and chemical stability, and improve the effect of low discharge voltage platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0030] Positive electrode production

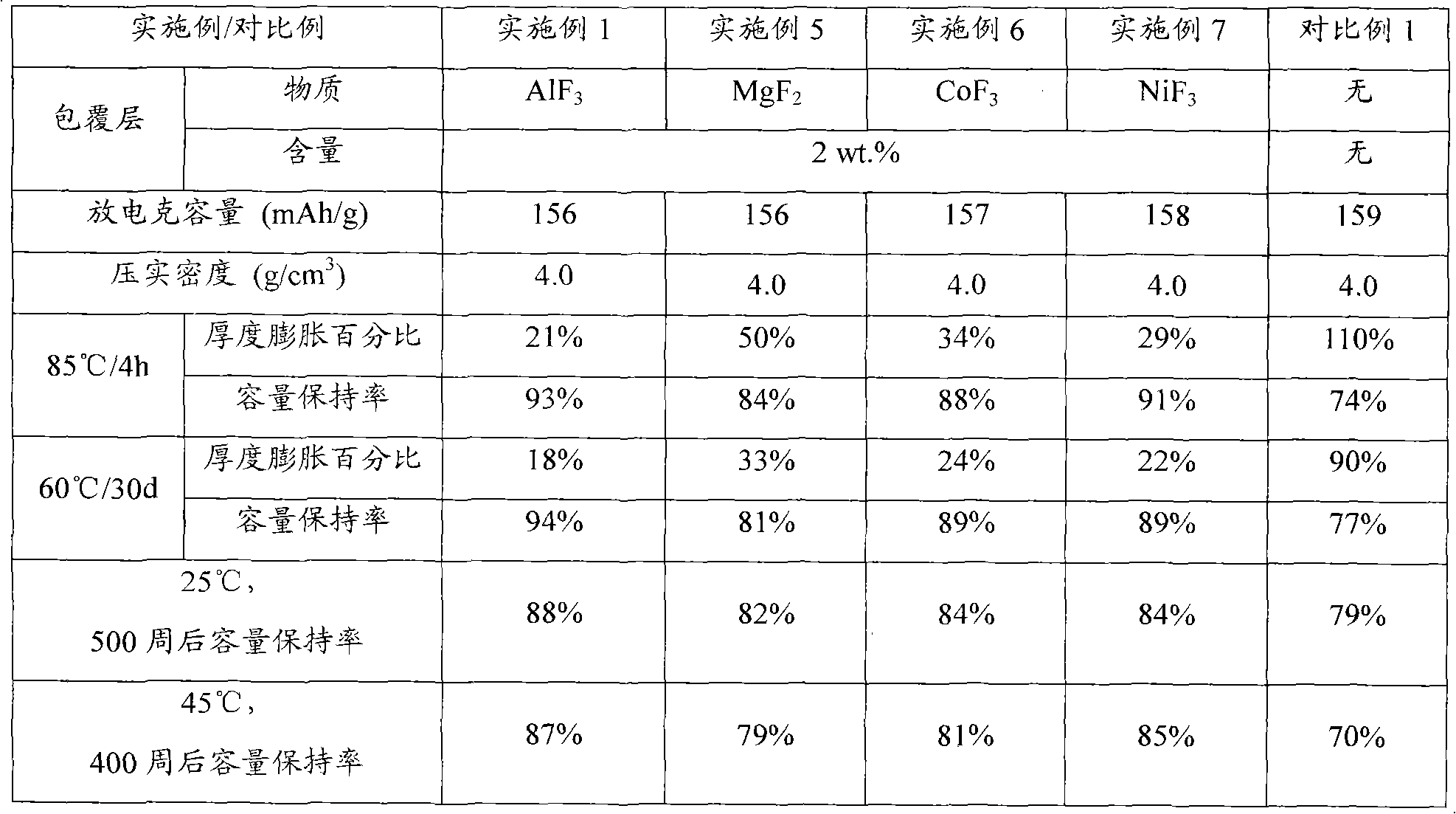

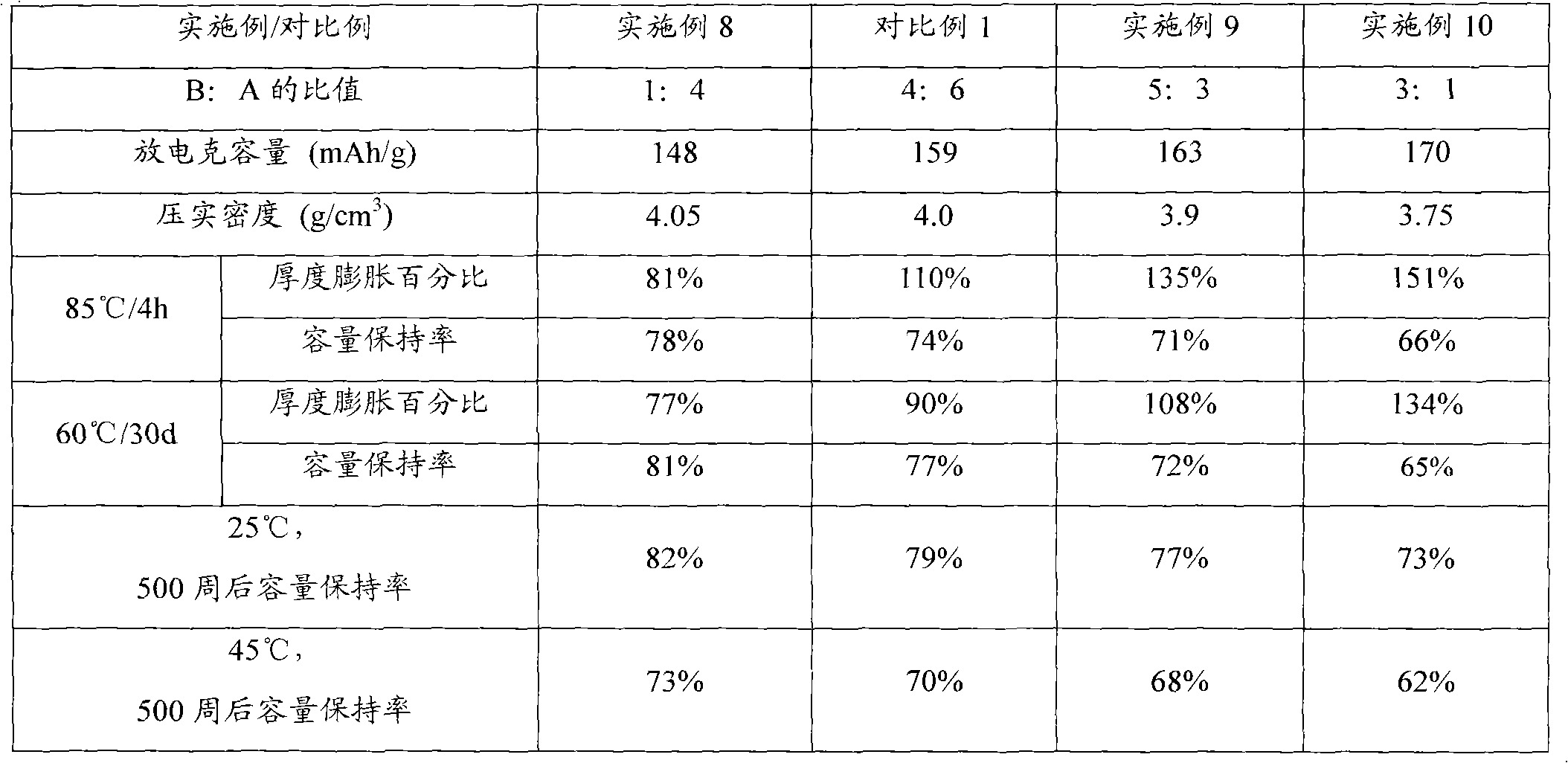

[0031] Use LiCoO with an average particle diameter D50 of 18 μm 2 As the lithium cobaltate-based active material A; use LiNi with an average particle diameter D50 of 9 μm 0.80 co 0.15 Al 0.05 o 2 As the high-nickel active material B, after mixing uniformly in the mixing tank according to the ratio of B:A=4:6, according to the above-mentioned surface coating treatment process, the surface of the mixed positive electrode active material is coated with 2wt% AlF 3 .

[0032] In a 5L mixer, add 104g PVDF to 1750g NMP under stirring, add 87.8g conductive agent after dissolving, stir at 40-50°C for 3 hours at high speed, cool to 20-25°C with circulating water, add 3058g of the above positive electrode active substance, vacuumized and stirred at high speed at 20-25°C for 3h. Coating and cold pressing the prepared cathode slurry.

[0033] The negative electrode is prepared in the water system according to the ratio of graphite: thickener CM...

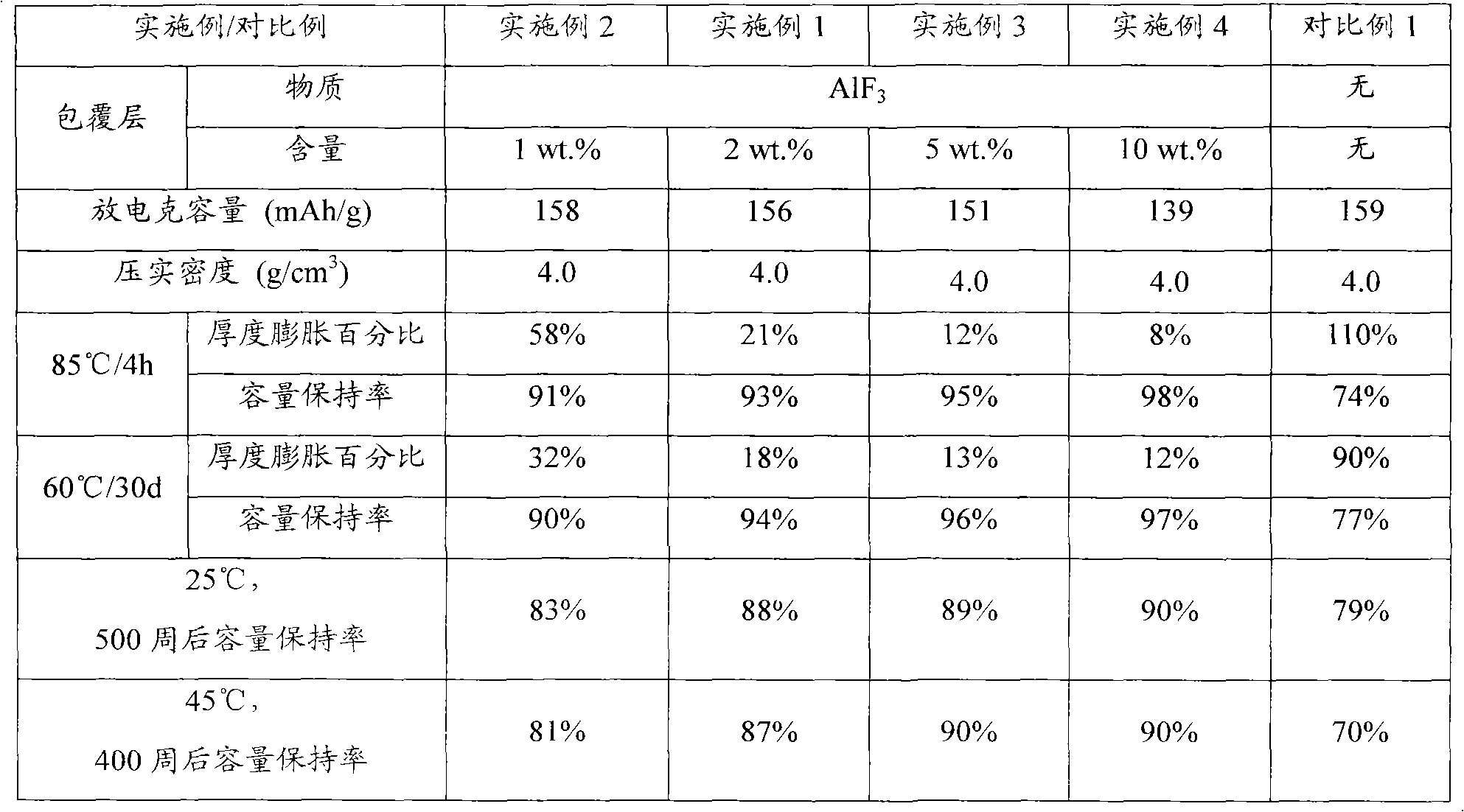

Embodiment 2

[0035] The difference from Example 1 is that the surface of the positive electrode active material is coated with AlF 3 The content of is 1wt%, and others are consistent with embodiment 1.

Embodiment 3

[0037] The difference from Example 1 is that the surface of the positive electrode active material is coated with AlF 3 The content of is 5wt%, and others keep consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com