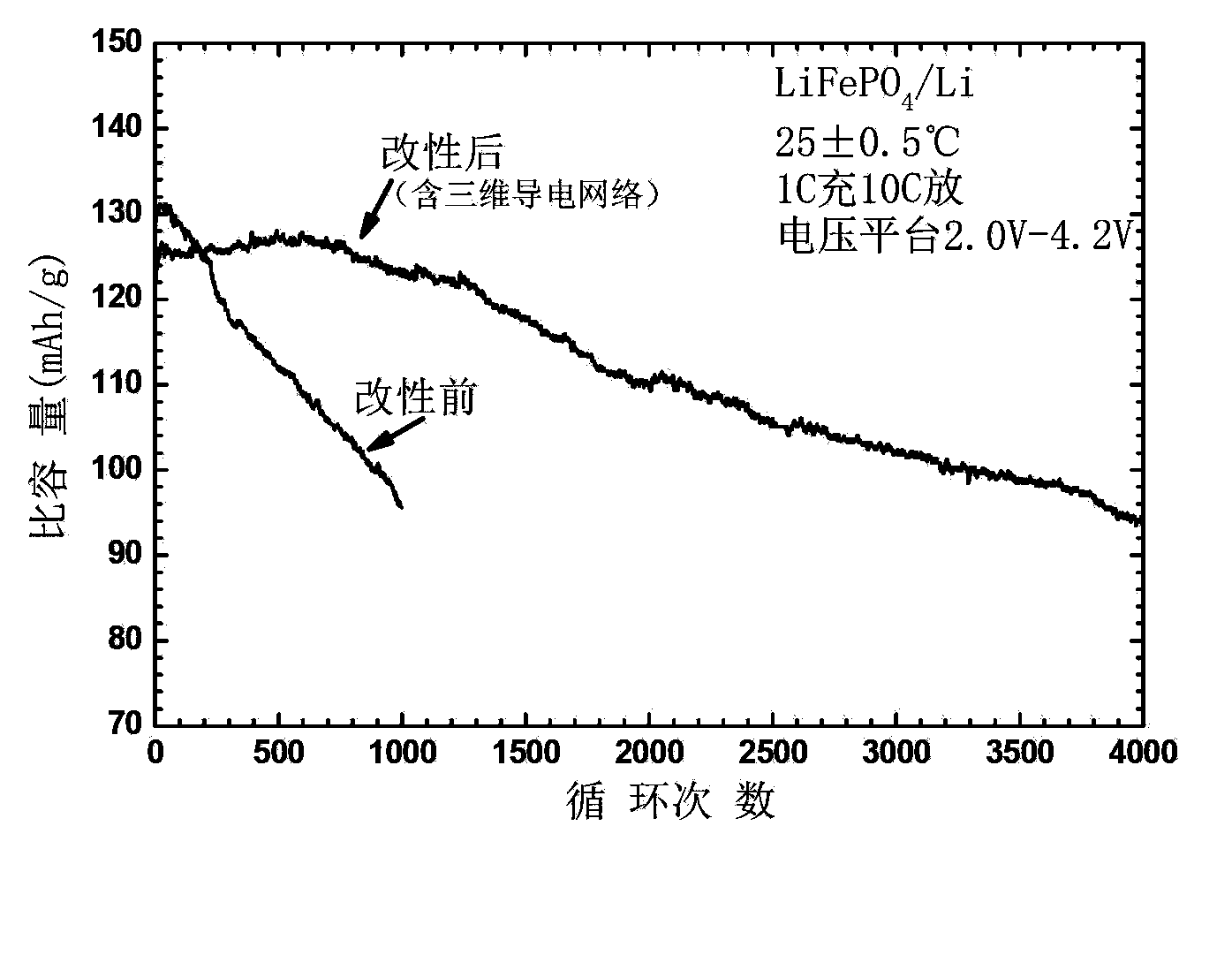

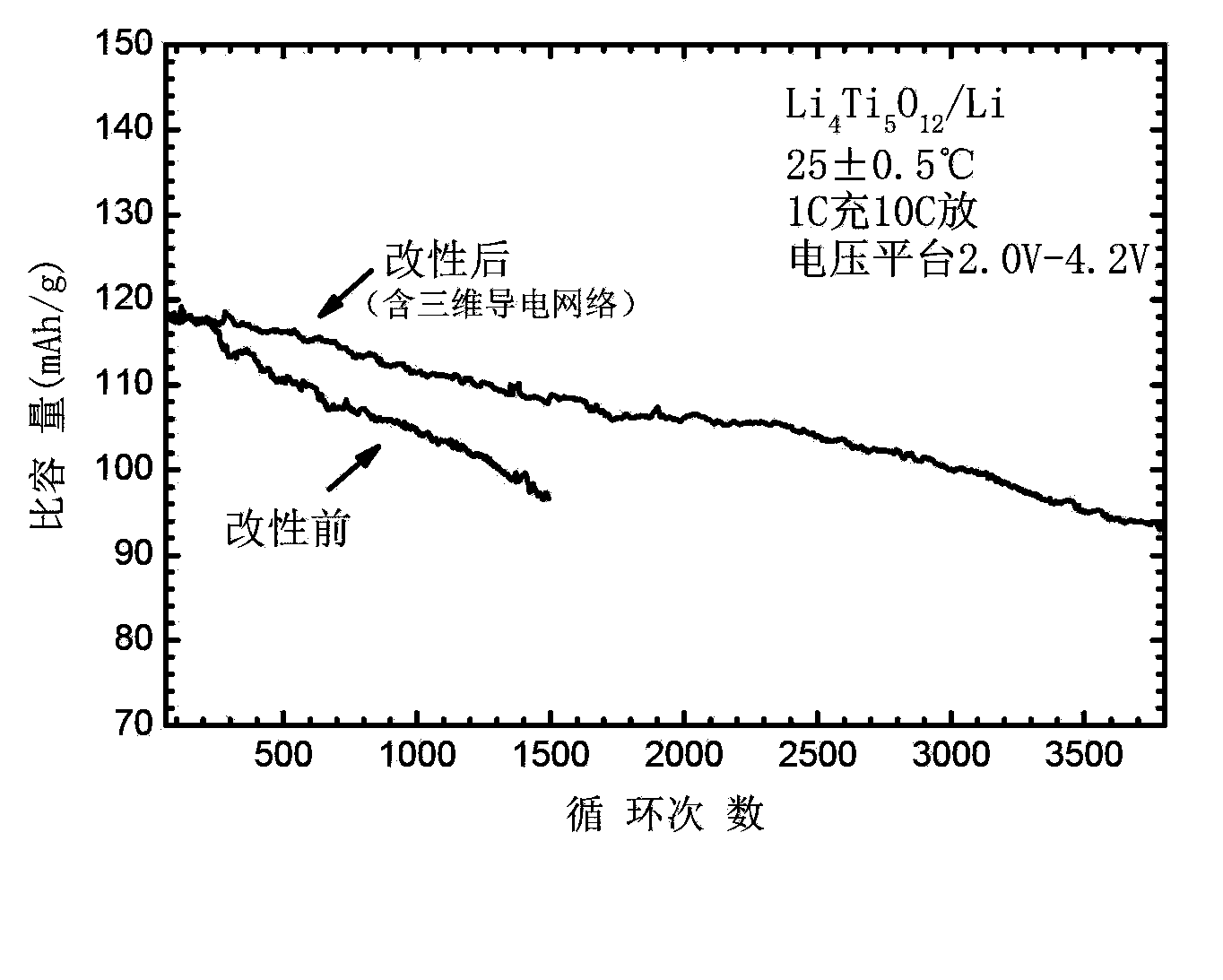

Lithium ion battery nano composite positive-negative electrode material containing three-dimensional conductive network as well as preparation method thereof

A lithium-ion battery and conductive network technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high rate performance and poor cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Add 0.1 gram of surfactant to 100 ml of water to fully dissolve at room temperature, add 0.1 gram of silver nanowires to the solution, sonicate (1-10) hours, and stir (1-24) hours to obtain uniform and stable silver nanowire dispersion; then add zero-dimensional conductive nanomaterials (0.1-2) grams, water-soluble binders (0.1-1) grams, lithium iron phosphate / lithium titanate (7.5-9.5) grams in sequence, and ultrasonically (0.1 -10) hours, stirring for (0.1-10) hours, to obtain a lithium-ion battery nanocomposite material with a three-dimensional spatial conductive network.

Embodiment 2

[0039] Add 0.1 gram of surfactant to 100 ml of water to fully dissolve at room temperature, add 0.1 gram of silver nanorods to the solution, ultrasonically (1-10) hours, and stir (1-24) hours to obtain a uniform and stable silver nanorod dispersion; then add zero-dimensional conductive nanomaterials (0.1-2) grams, water-soluble binders (0.1-1) grams, lithium iron phosphate / lithium titanate (7.5-9.5) grams in sequence, and ultrasonically (0.1 -10) hours, stirring for (0.1-10) hours, to obtain a lithium-ion battery nanocomposite material with a three-dimensional spatial conductive network.

Embodiment 3

[0041] Add 0.1 gram of surfactant to 100 ml of water to fully dissolve at room temperature, add 0.1 gram of copper nanowires to the solution, sonicate (1-10) hours, and stir (1-24) hours to obtain uniform and stable copper nanowire dispersion; then add zero-dimensional conductive nanomaterials (0.1-2) grams, water-soluble binders (0.1-1) grams, lithium iron phosphate / lithium titanate (7.5-9.5) grams in sequence, and ultrasonically (0.1 -10) hours, stirring for (0.1-10) hours, to obtain a lithium-ion battery nanocomposite material with a three-dimensional spatial conductive network.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com