Circulating fluidized bed boiler

A circulating fluidized bed and boiler technology, which is applied in the field of mechanical equipment, can solve the problems of affecting the air supply of the return material, over-temperature coking of the return material device, and wear of the air cap, so as to solve the wear of the air cap, stabilize the operation of the return material, and solve the problems of the air chamber The effect of pouring gray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

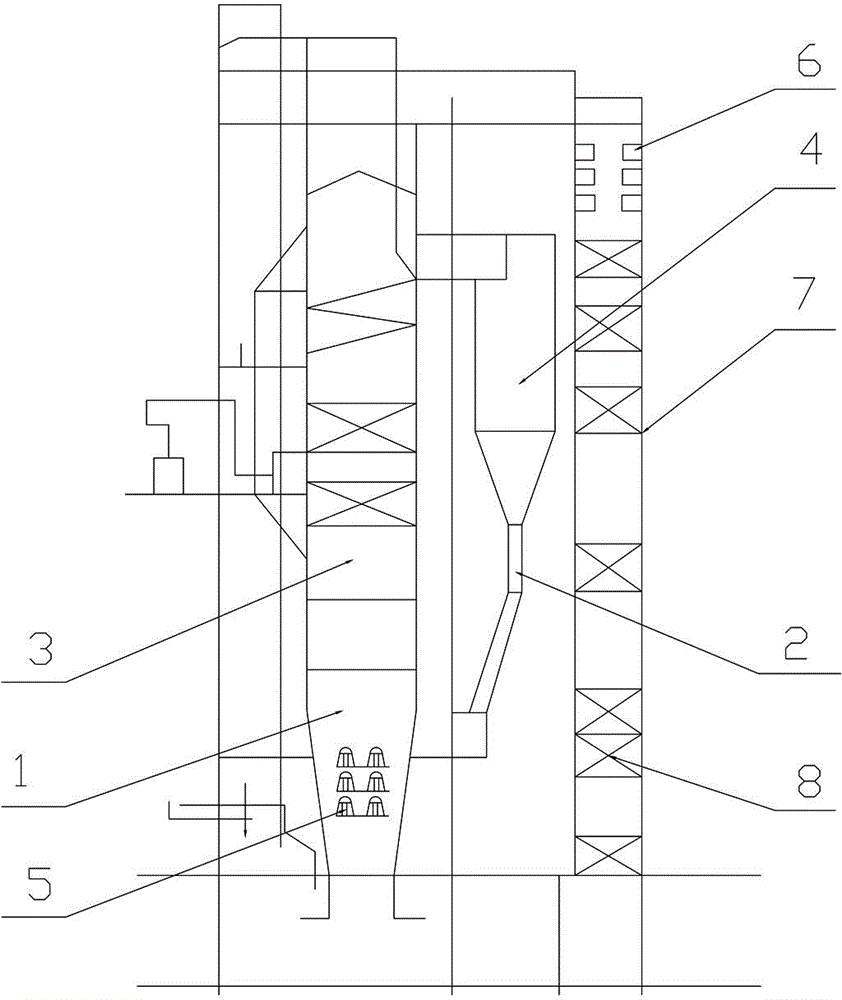

[0011] The circulating fluidized bed boiler of the present invention includes a furnace cavity 1, a feeder 2, and a combustion chamber 3, a cyclone separator 4, and a tail flue arranged in sequence from front to back, and the furnace 1 is a fully suspended water-cooled wall, and the water-cooled wall distributes air. Wind caps 5 are evenly arranged on the board, and high-temperature superheaters are suspended above the tail flue; low-temperature superheaters, economizers 7, and air preheaters 8 are supporting structures; There are four rows of columns, the hood 5 is changed to a small bell type hood, the upper end of the hood is connected to a hood head through a jacket, and an inner tube core is arranged in the hood, the labyrinth structure completely solves the problem of slag dumping, and the smaller volume and The diameter of the small hole greatly reduces the wear of the hood head. The setting of the jacket completely avoids the wear of the inner tube core. The slot connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com