Coal mill pulverized coal fineness online monitoring method

A technology of pulverized coal fineness and pulverizer, applied in the direction of analyzing materials, instruments, etc., can solve the problems of low combustion efficiency, inability to perform real-time adjustment, and high power consumption for pulverizing, and achieve good economic results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

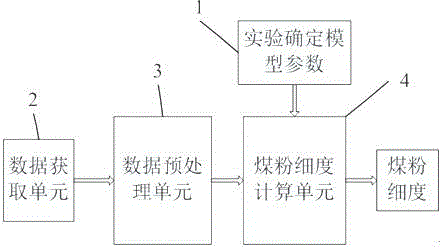

[0020] like figure 1 As shown, it is an online monitoring method for pulverized coal fineness of a coal mill. The pulverized coal fineness online monitoring system includes a data acquisition unit 2, a data preprocessing unit 3, and a pulverized coal fineness calculation unit 4; the method includes the following steps:

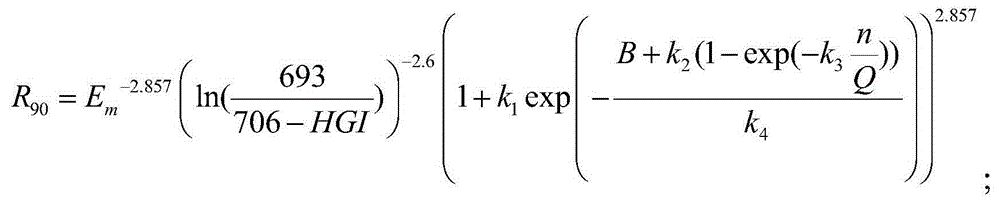

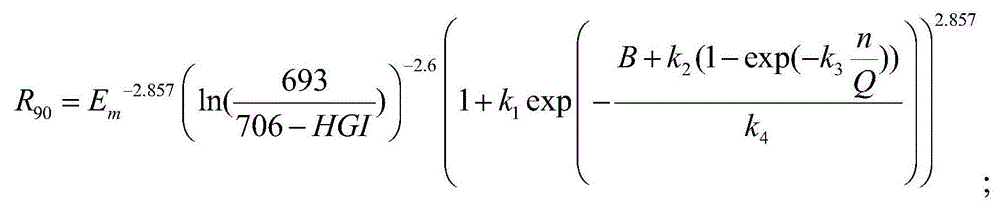

[0021] 1) Experimental determination of model parameters 1: Before use, first conduct the coal mill variable dynamic separator speed test, the variable coal mill inlet primary air volume test, and the variable coal mill output test. During the test, the separator speed and the coal mill inlet are collected. The data of primary air volume, coal feed rate of coal feeder, coal mill current and coal Hastelloy's grindability index, and off-line measurement of coal fineness for coal powder sampling, and then use the least square method or other parameter opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com