Circulating fluidized bed boiler device using low calorific value coal gangue for post ignition

A technology of circulating fluidized bed and boiler equipment, which is applied in the directions of fluidized bed combustion equipment, fuel burned in a molten state, combustion type, etc. The effect of improving boiler efficiency and low fluidizing wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

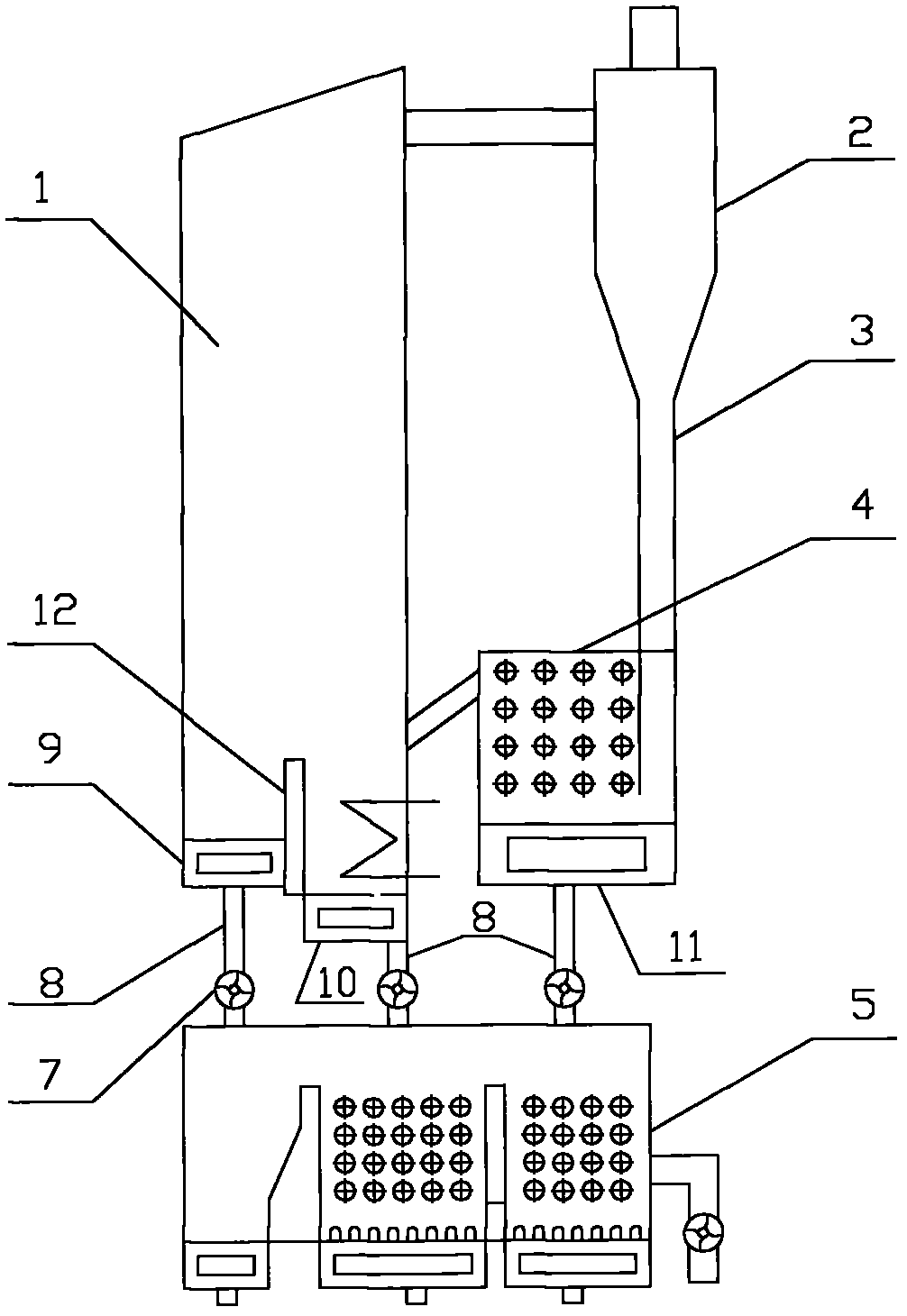

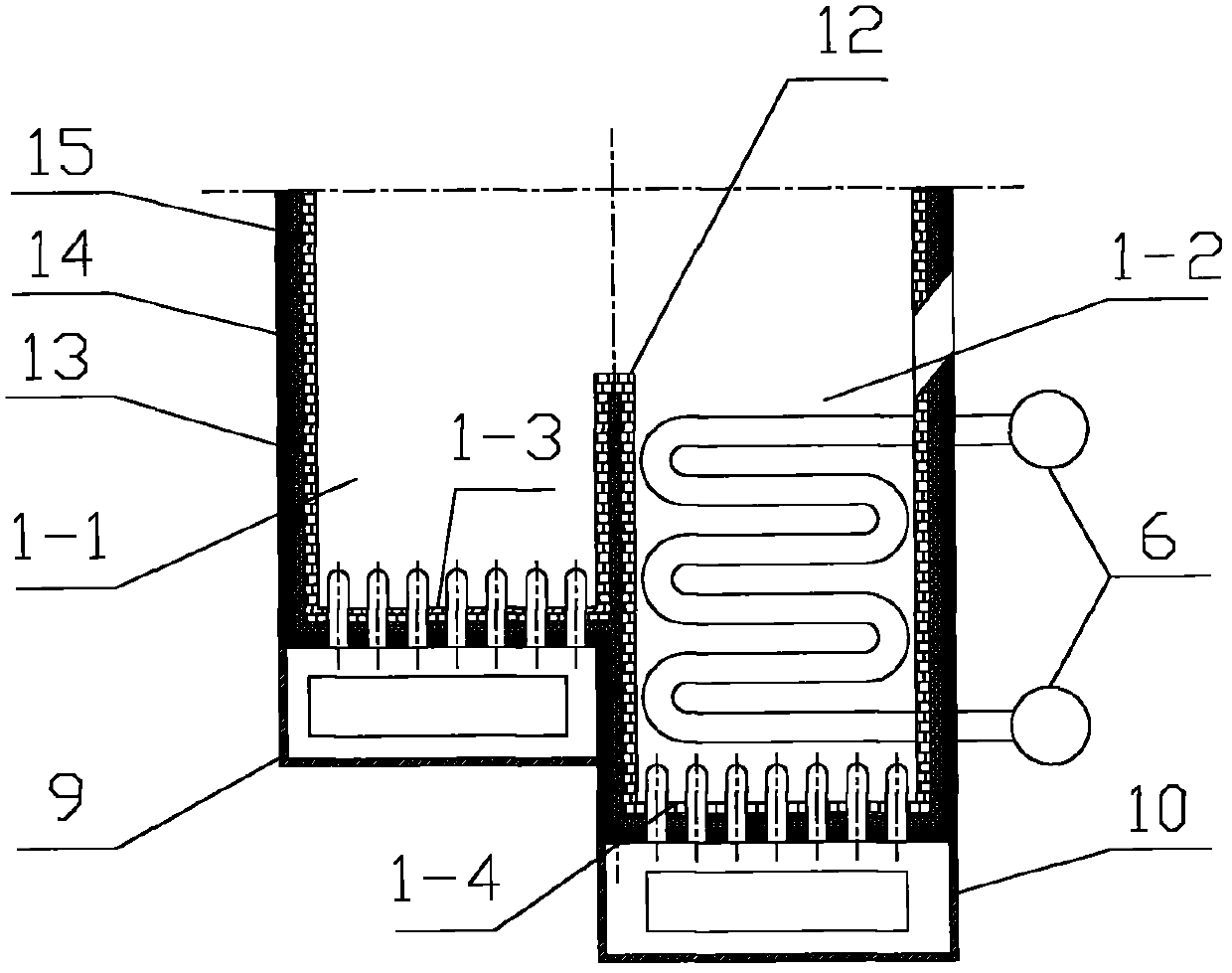

[0025] A kind of circulating fluidized bed boiler device of this embodiment purely burning coal gangue with low calorific value is as follows: figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 7 , Figure 8 and Figure 9 As shown, including furnace 1, cyclone separator 2, standpipe 3, circulating ash heat exchanger 4, fluidized bed slag cooler 5, header 6, high temperature slag inlet valve 7, fluidized bed slag cooler slag inlet pipe 8. Coarse particle fluidized bed air chamber 9, fine particle fluidized bed air chamber 10, circulating ash heat exchanger air chamber 11 and furnace middle partition wall 12. The bottom of the furnace 1 is divided into a fine particle fluidized bed 1-2 and a coarse particle fluidized bed 1-1 by a partition wall 12 in the furnace, wherein the coarse particle fluidized bed 1-1 is an adiabatic combustion zone, and the fine particle fluidized bed 1 -2 Arrange serpentine tube type evaporation heating surface; both fluidized beds adopt hood ...

Embodiment 2

[0028] A kind of circulating fluidized bed boiler device of this embodiment purely burning coal gangue with low calorific value is as follows: figure 1 , figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 10 and Figure 11 As shown, the structure is different from Embodiment 1 in that the heating surface 5-12 of the first water-cooled cooling chamber and the heating surface 4-1 of the circulating ash heat exchanger are all in the form of serpentine tubes, and the rest of the structure is the same as that of Embodiment 1.

Embodiment 3

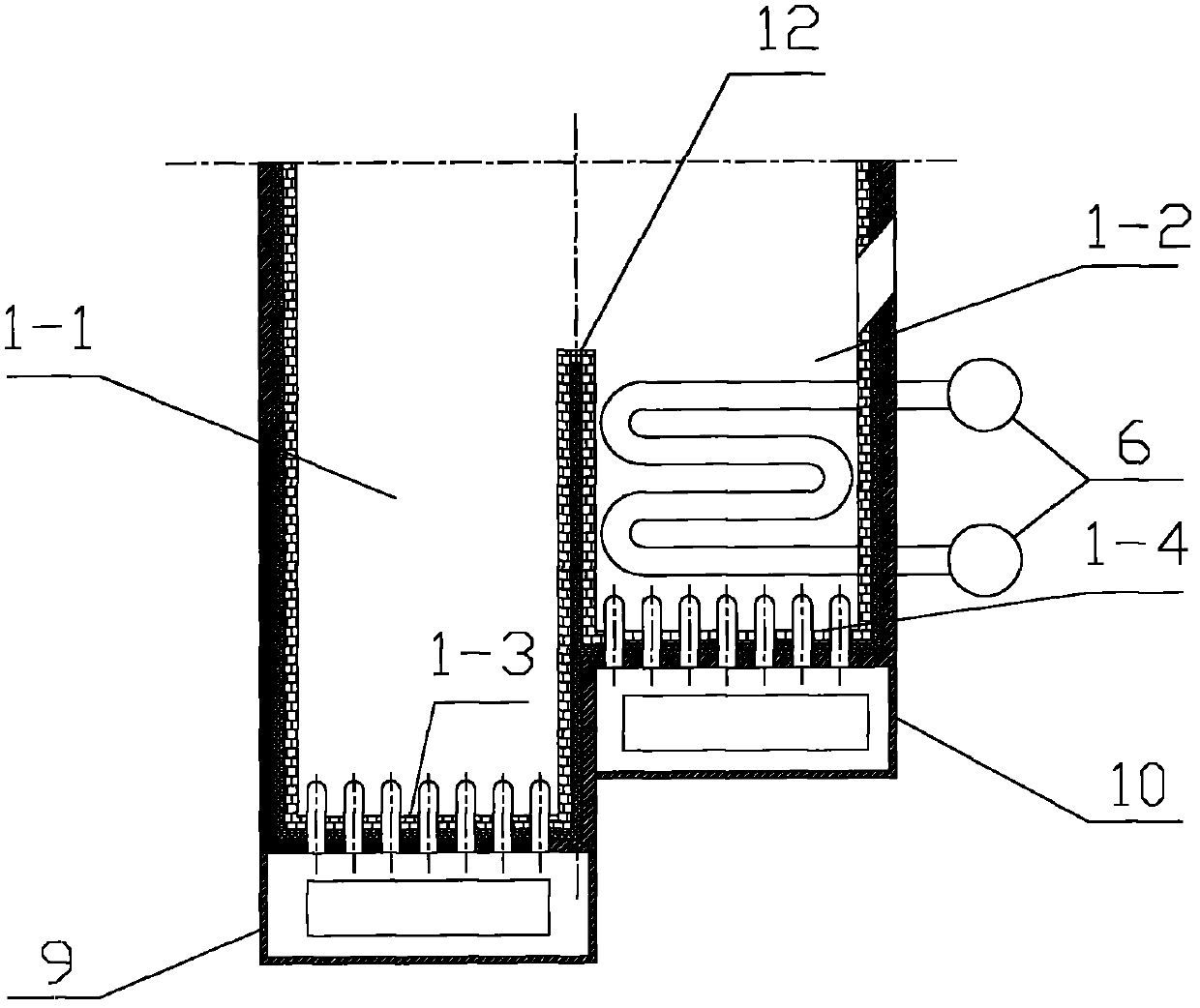

[0030] A kind of circulating fluidized bed boiler device of this embodiment purely burning coal gangue with low calorific value is as follows: figure 1 , image 3 , Figure 4 , Figure 5 , Figure 7 , Figure 8 and Figure 9 As shown, the structure is different from Example 1 in that in the bottom structure of the furnace, the coarse particle fluidized bed air distribution plate 1-3 is 0-600mm lower than the fine particle fluidized bed air distribution plate 1-4, and the rest of the structure and implementation Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com