Hot stamping forming steel added with Ce alloy and hot stamping forming technology

A technology of hot stamping forming and alloy, which is applied in the field of hot stamping forming steel and hot stamping forming technology, to achieve the effect of solving the problem of mold wear, stable and compact structure, and eliminating the need for shot blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

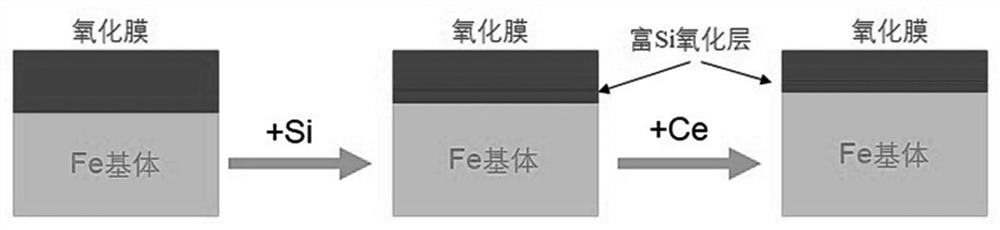

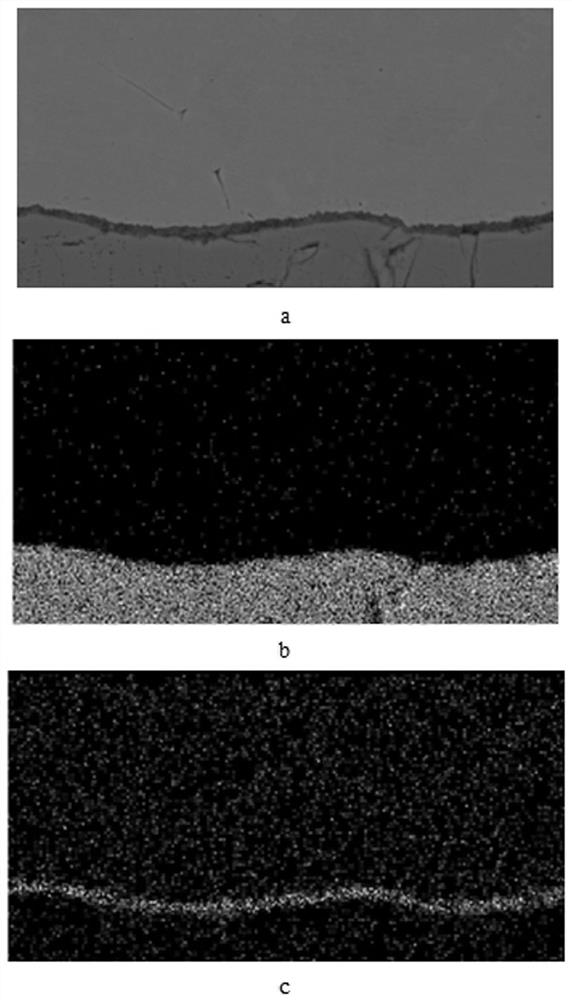

[0039] Example 1 The principle of Ce-rich and Si-rich oxide layers changing the surface structure of hot-formed steel.

[0040] It adopts the chemical composition design of traditional hot forming steel 22MnB5. Hot stamping forming steel adopts heating, austenitic stamping and quenching, therefore, adopts high carbon composition design, traditional hot forming steel 22MnB5 composition: C 0.20~0.25%, Mn 0.1~1.5%, Si less than 0.8%, Cr less than 0.5% , Al is less than 0.5%, Ti is less than 0.1%, B is not less than 0.001%, and the balance is Fe and inevitable inclusions.

[0041] There is no oxide layer on the surface of normal hot-formed steel raw materials. During the continuous annealing production, the surface of 100% pure iron is obtained after bright annealing; the pickling plate is delivered, and the pickling process after hot rolling is adopted to remove the surface oxide layer to obtain a material with a surface of pure iron structure. During the use of hot-formed stee...

Embodiment 2

[0044] 1. Screening experiments on the chemical composition and dosage of the hot-pressed steel sheet of the present invention.

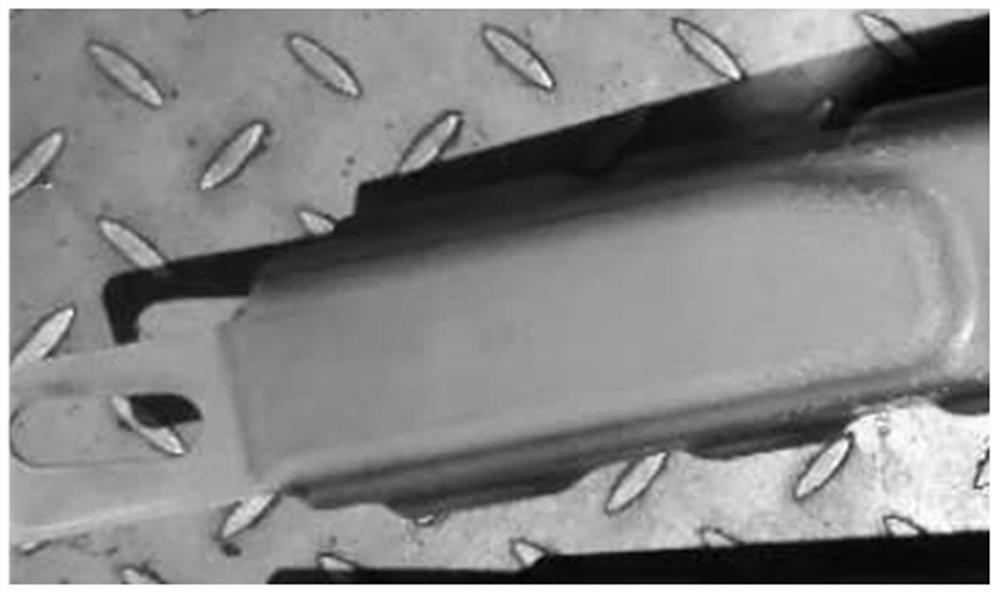

[0045] Thermoforming process: thermoforming material blanking → heating → hot stamping → quenching → laser cutting → finished product.

[0046] The hot stamping forming process of the steel for hot stamping forming with the addition of Ce alloy, the hot stamping forming process includes the following steps.

[0047] Step 1. The heating temperature is 920-950° C., and the holding time is 3-5 minutes to achieve austenitization, which meets the requirements of the hot-press forming process.

[0048] Step 2. After the sheet is transferred, the stamping mold clamping temperature is higher than 750°C.

[0049] Step 3. After closing the mold, pressurize and cool normally, and the mold opening temperature is less than 200°C.

[0050] The test steel was prepared according to the different compositions of the hot stamping steel in Table 1, and the performan...

Embodiment 3

[0058] Example 3 A method for preparing a steel for hot stamping with the addition of a Ce alloy.

[0059] The preparation of the Ce alloy-added steel for hot stamping of the present invention is carried out according to the following preparation method.

[0060] 1. Steelmaking.

[0061] 1. Smelting and refining.

[0062] After the molten iron is pretreated, converter steelmaking, out-of-furnace refining technology, and continuous casting process are adopted, and finally a continuous casting slab with qualified composition meeting the design requirements is obtained. Among them, ladle Al is controlled at 0.01-0.015%. At the end of refining, when the oxygen content is guaranteed to be low enough, add Ce-rich cored wire through the wire feeder (it can also be added by adding Ce metal, Ce-Fe alloy and other Ce-rich raw materials in the form of powder, block, etc.).

[0063] 2. Continuous casting process.

[0064] Protective pouring is carried out throughout the pouring proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com