Method for producing all-stone burn-free architectural ornament polished tile and formula thereof

A technology for building decoration and production method, which is applied in the field of building decoration materials to achieve the effects of strong stain resistance, strong stain resistance, compact and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

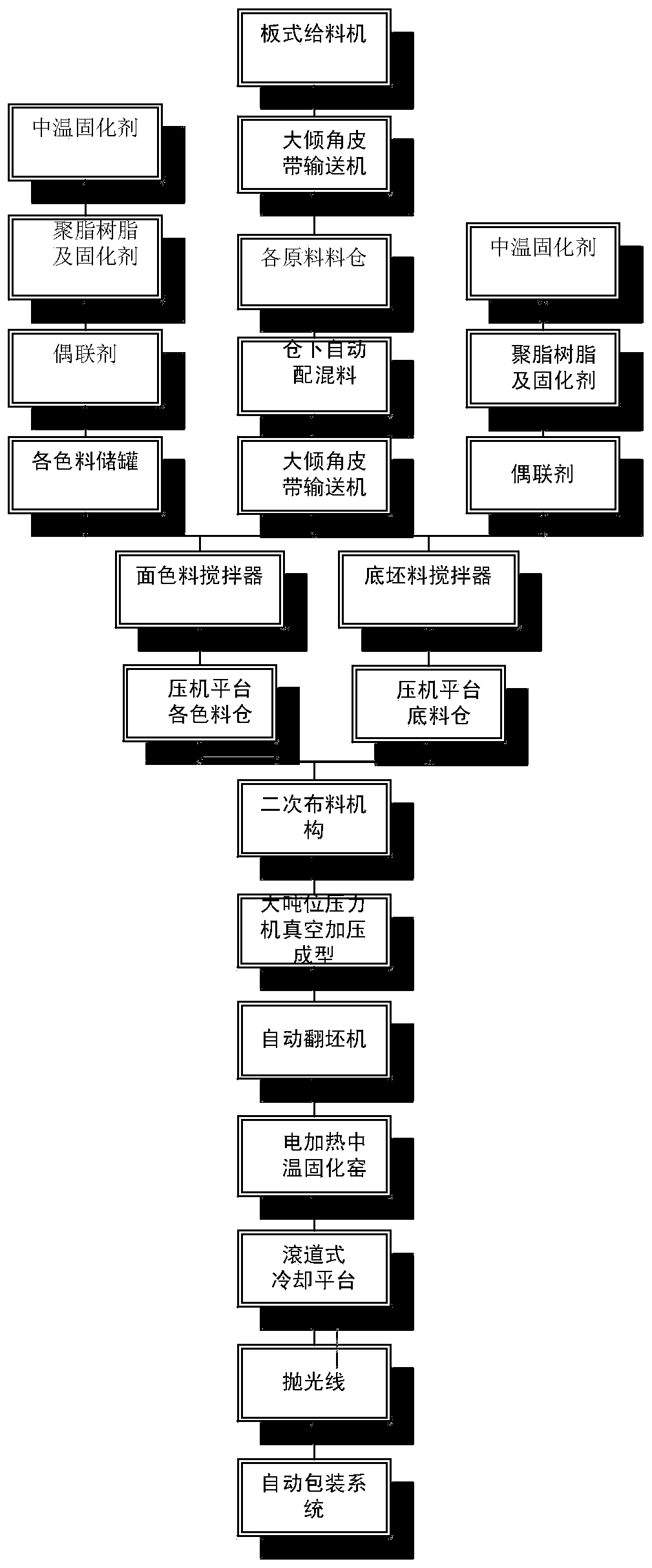

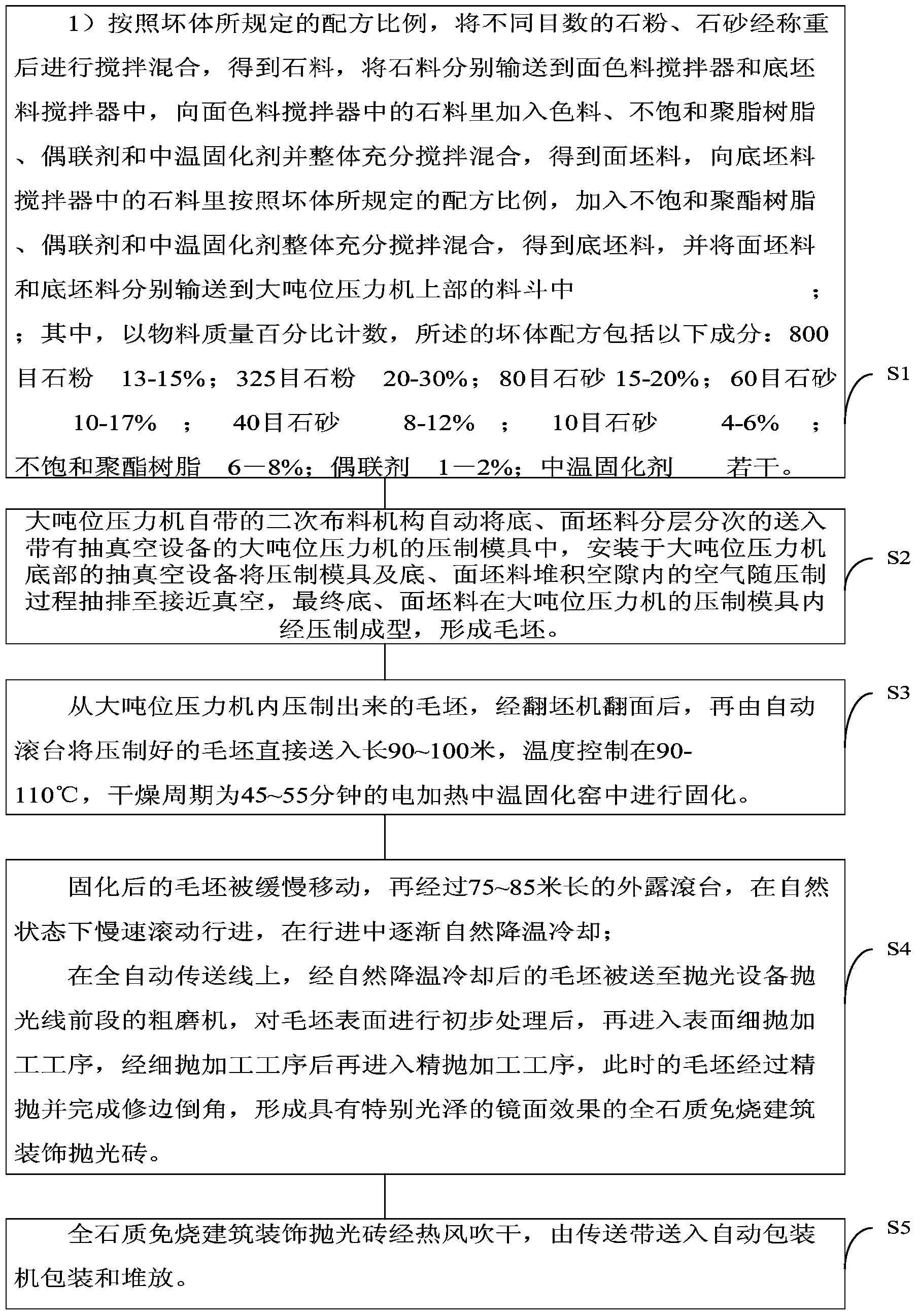

[0039] The production method overview of the all-stone non-fired building decoration polished brick provided by the invention:

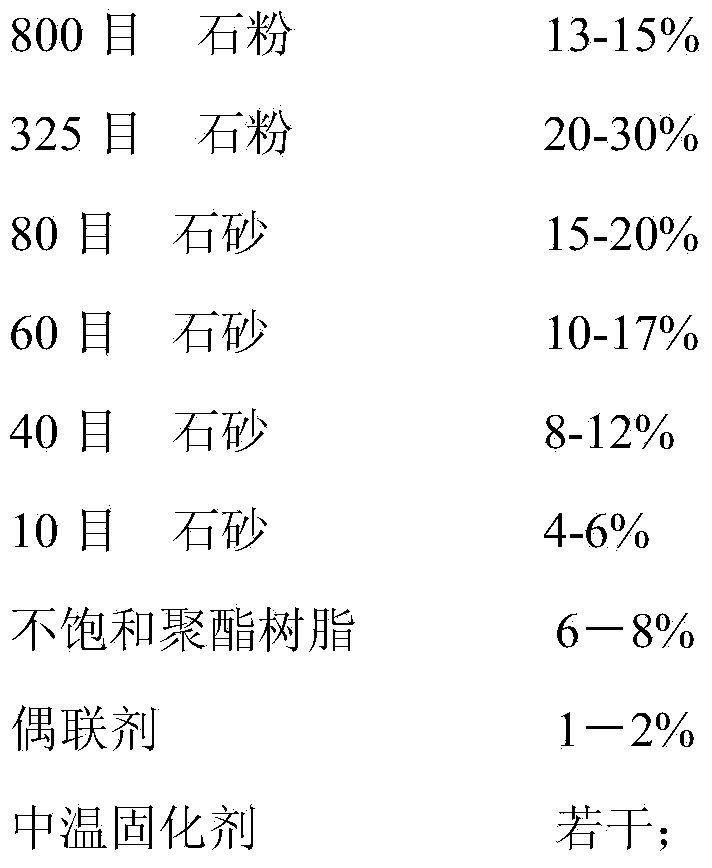

[0040] First of all, according to the formula ratio stipulated by the green body, mix the stone powder and stone sand of different meshes well, add resin, coupling agent, curing agent or resin, coupling agent, curing agent and color paste to it respectively, The whole is fully stirred and mixed, and then the mixed bottom and surface blanks are transported to the upper hopper of the large-tonnage press, and the secondary material distribution mechanism of the large-tonnage press automatically separates the bottom and surface blanks in layers. Send it into the mold of a large tonnage press. After the automatic press controlled by the computer program is vacuum-presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com