Shot-blasting intensifying and cleaning device for inner and outer walls of petroleum drilling rod

A technology for oil drill pipes and cleaning devices, which is applied to used abrasive processing devices, abrasives, metal processing equipment, etc. It can solve the problems of no shot blasting treatment process, improve wear resistance and strength, and solve wear problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

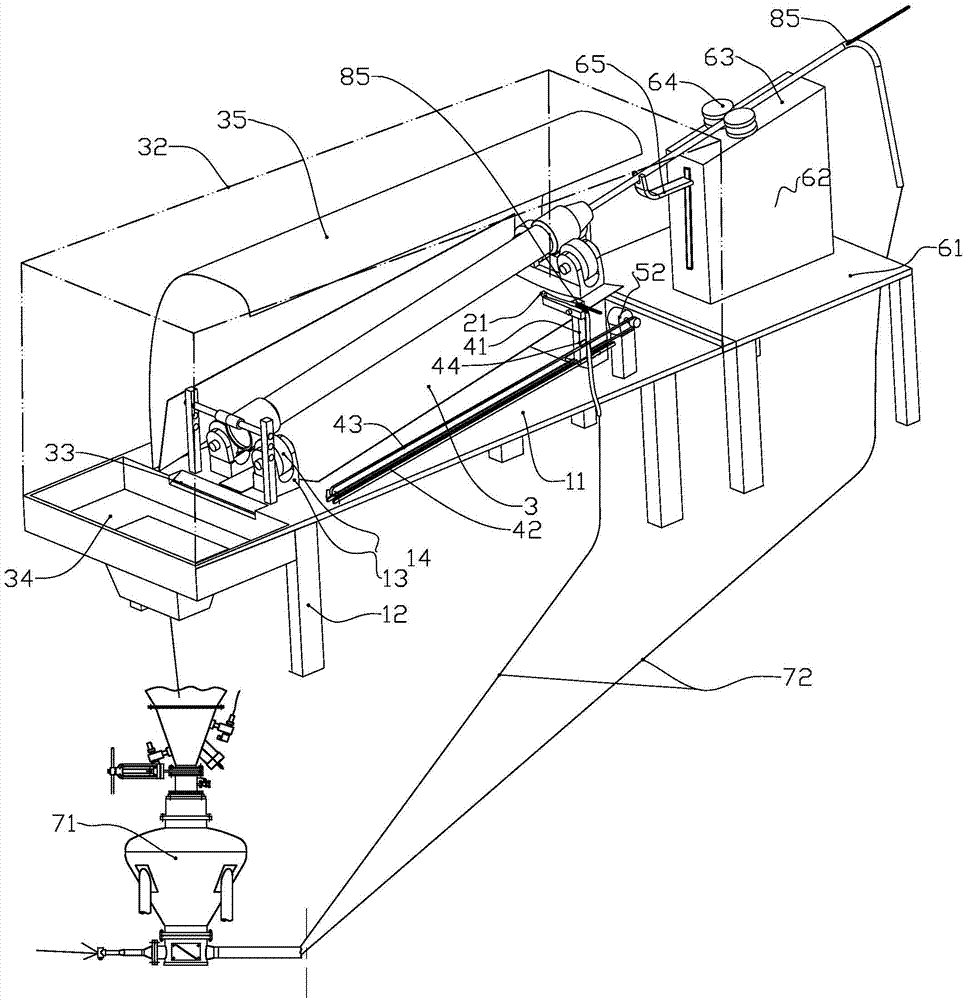

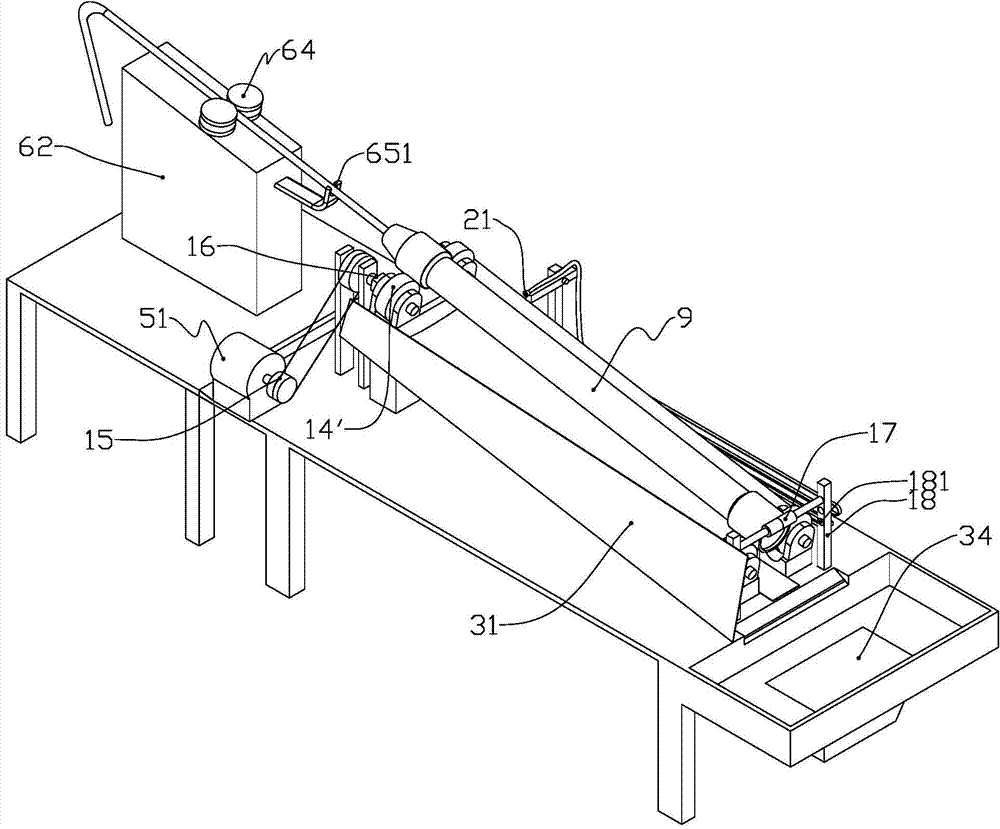

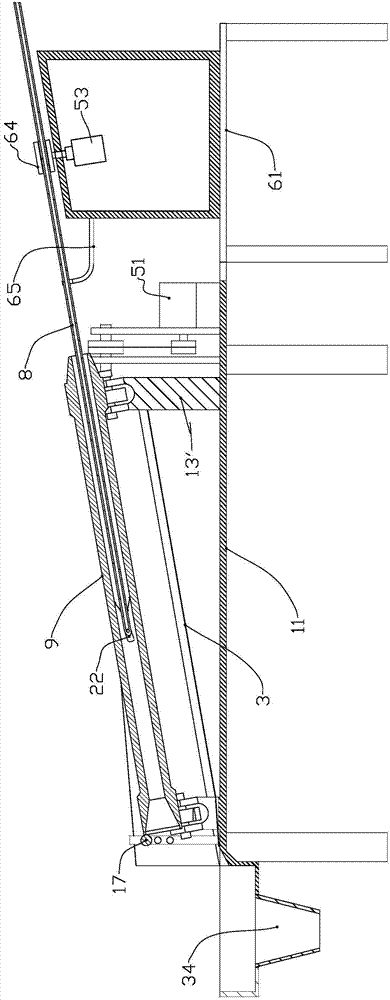

[0049] A shot blasting strengthening and cleaning device for the inner and outer walls of an oil drill pipe, including a support part, a driving power part and a pneumatic shot blasting part, wherein the support part mainly forms an inclined structure for supporting the oil drill pipe, so that the oil drill The two ends of the rod can be placed on the supporting rollers of the support part to form a support, and can rotate under the drive of the motor. In the support part, there is also a slope for collecting shot blasting and a protective cover for protecting the entire shot blasting space. The collected shot blasting blanking enters a pneumatic conveying bin, which is a device for conveying shot blasting. The shot blasting is transported to the corresponding pipeline through the pipeline. The pneumatic shot blasting part includes a first nozzle and a second nozzle. The first nozzle blasts the outer wall of the oil drill pipe, and the second nozzle cleans the inner wall. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com