Method for measuring key point of car frame based on coding points and computer vision

A computer vision and measurement method technology, applied in measurement devices, instruments, optical devices, etc., can solve problems such as difficult global control, large accumulated errors, and small single measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

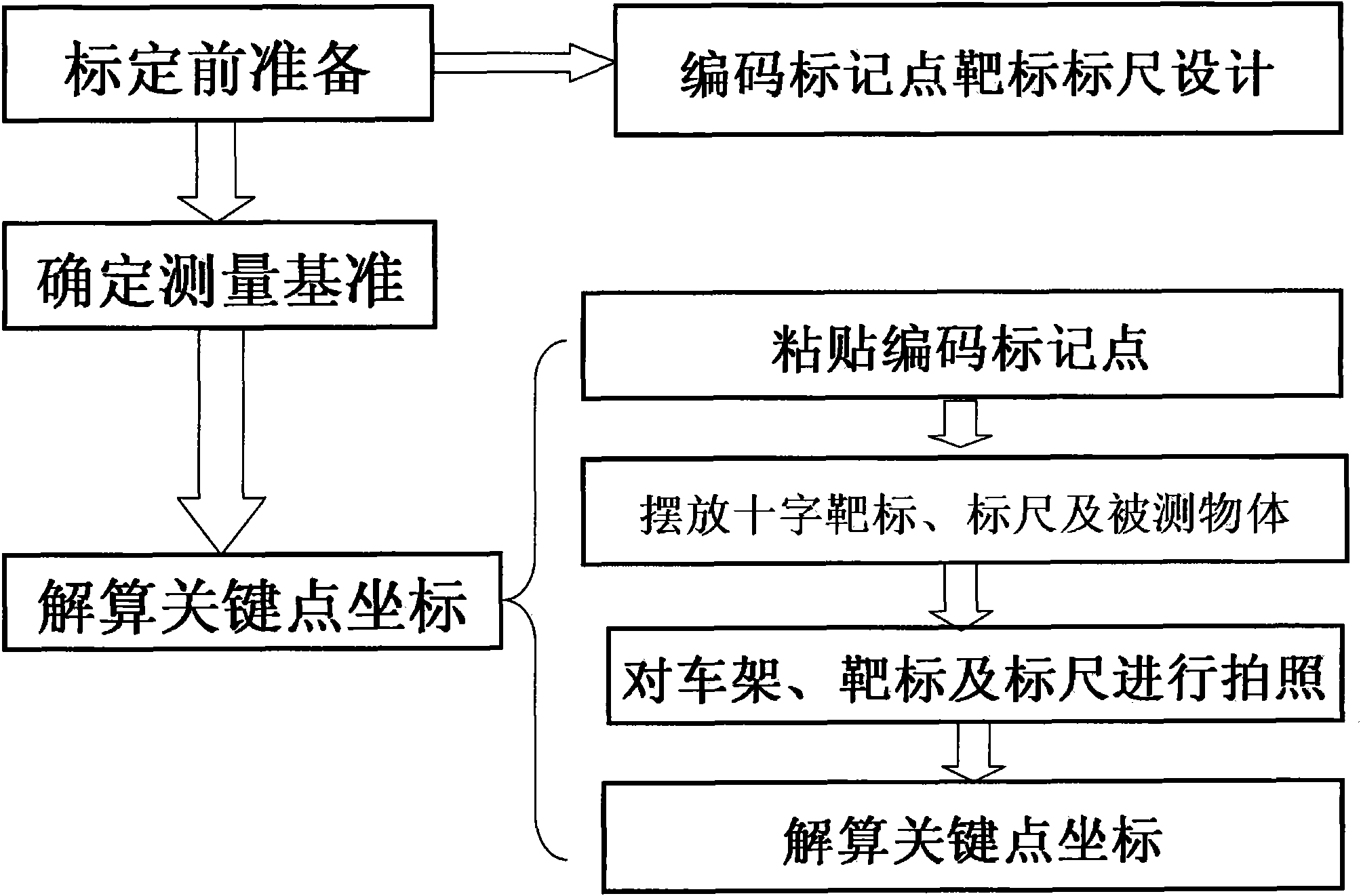

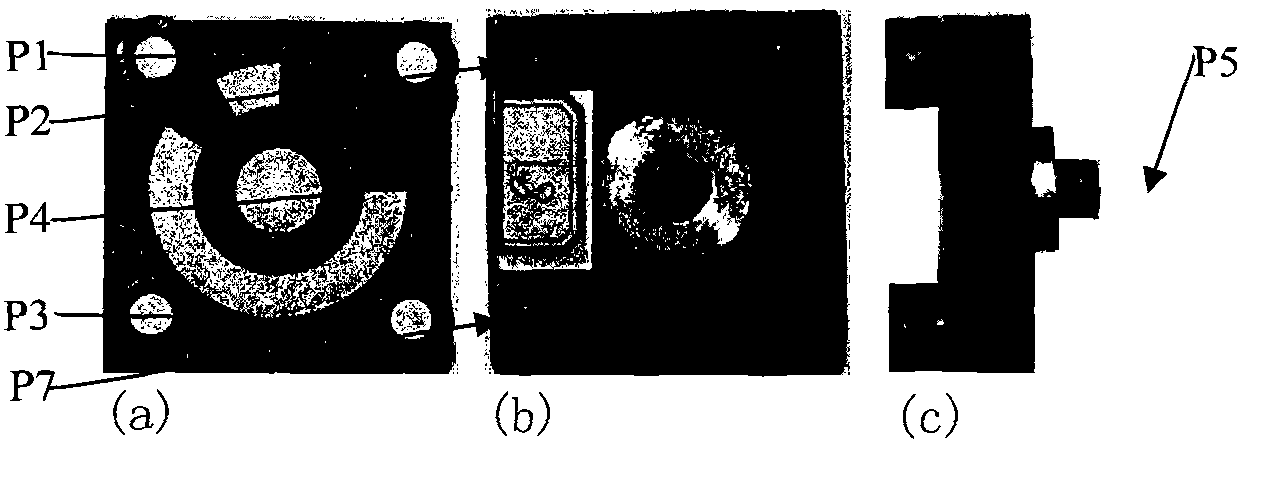

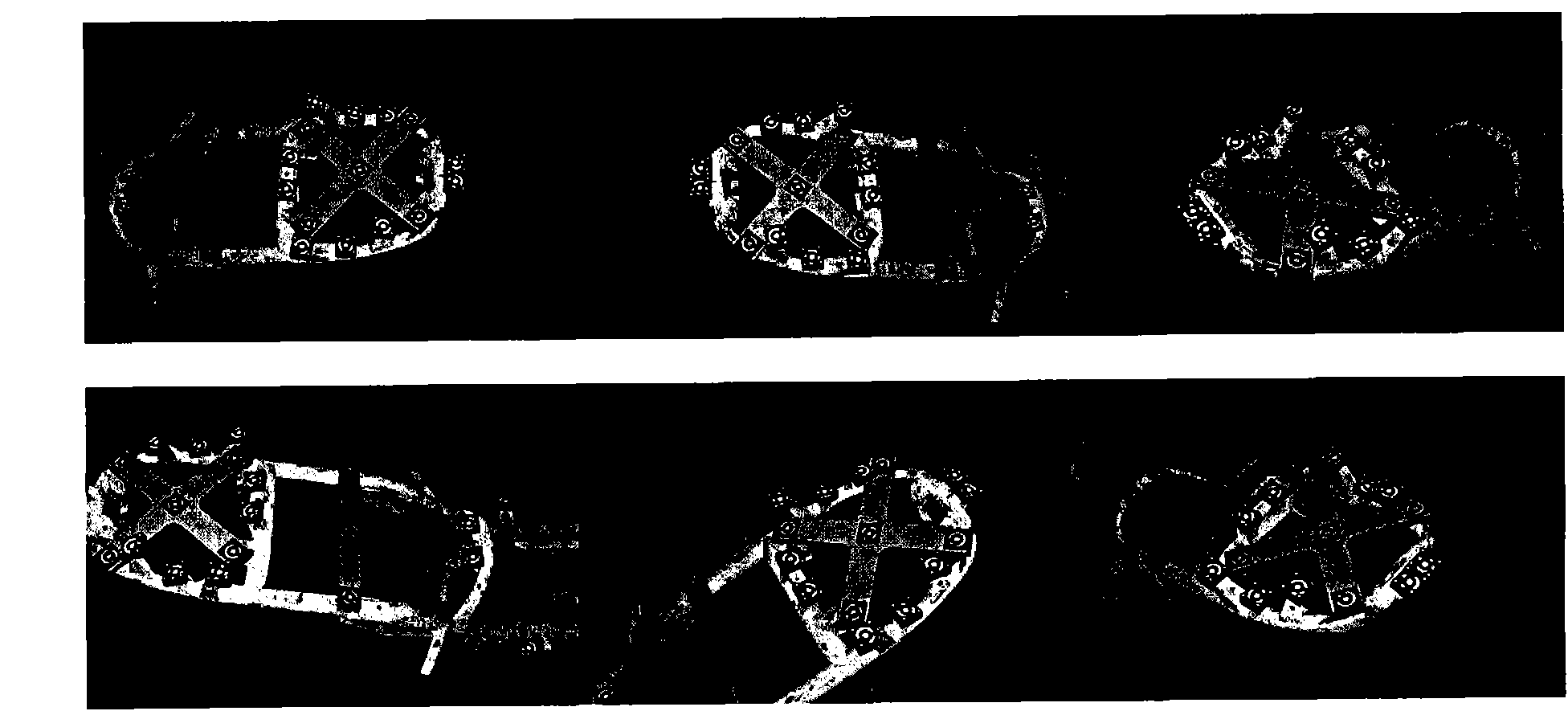

[0047]A specific implementation of the method for measuring key points of a vehicle frame based on coding points and computer vision is: designing and processing coding marking points, high-precision cross targets, and a ruler system; Marking points; place the cross target and the ruler near the measured object, the principle of placing the cross target and the ruler is: when using the high-precision digital camera to take pictures of the cross target and the ruler, the cross target and the ruler can be photographed at the same time At least three coded marking points other than the cross target and ruler; use the high-precision digital camera to take pictures of the measured object containing the cross target and ruler, change the shooting position and angle and continue to shoot the measured object, and collect at least 3 pictures The image of the measured object containing the cross target; use the high-precision digital camera to continue to take pictures of the measured ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com