Control method for tooth shape size precision of cold forming straight bevel gear

A technology of straight bevel gears and dimensional accuracy, which is applied in manufacturing tools, forming tools, forming tools for metal extrusion, etc. The effect of tooth profile dimensional accuracy, excellent contact and transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

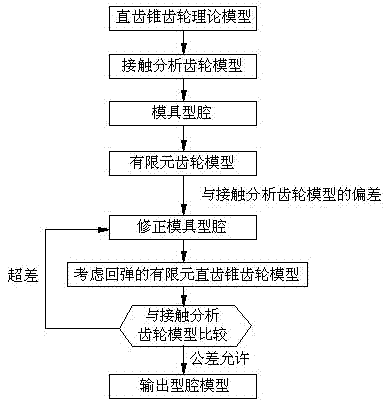

[0031] The process flow of the control method of the tooth shape dimensional accuracy of the cold-formed straight bevel gear of the present invention is as follows figure 1 , the steps are:

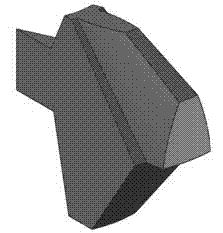

[0032] 1) According to the theoretical model of straight bevel gear, the modified contact analysis gear model is determined according to the contact analysis. The contact analysis gear model is as follows: figure 2 shown;

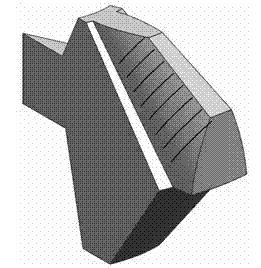

[0033] 2) The mold cavity under the cold forming process is generated from the contact analysis gear model;

[0034] 3) According to the mold cavity, the finite element analysis of the forming process is carried out to determine the finite element gear model after considering springback;

[0035] 4) Compare the finite element gear model obtained in step 3) with the contact analysis gear model in step 1) to obtain the model deviation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com